Star delta starters reduce the initial current by starting the motor in a star configuration, then switching to delta for full power, making them ideal for applications requiring high starting torque. Soft starters gradually ramp up voltage to limit inrush current, providing smoother acceleration and better control to protect your motor and extend its lifespan.

Table of Comparison

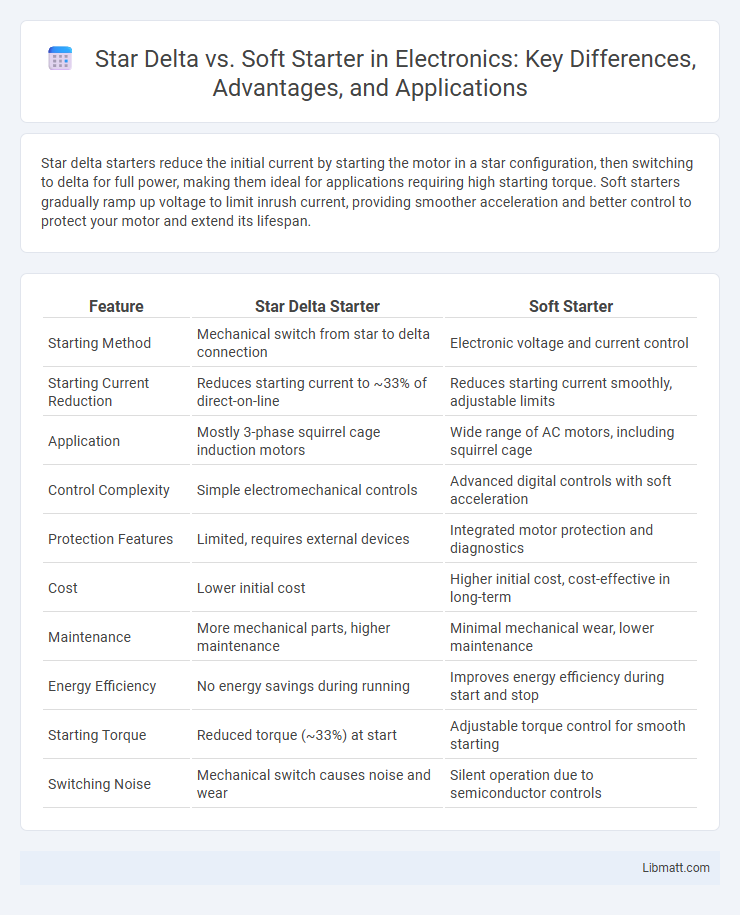

| Feature | Star Delta Starter | Soft Starter |

|---|---|---|

| Starting Method | Mechanical switch from star to delta connection | Electronic voltage and current control |

| Starting Current Reduction | Reduces starting current to ~33% of direct-on-line | Reduces starting current smoothly, adjustable limits |

| Application | Mostly 3-phase squirrel cage induction motors | Wide range of AC motors, including squirrel cage |

| Control Complexity | Simple electromechanical controls | Advanced digital controls with soft acceleration |

| Protection Features | Limited, requires external devices | Integrated motor protection and diagnostics |

| Cost | Lower initial cost | Higher initial cost, cost-effective in long-term |

| Maintenance | More mechanical parts, higher maintenance | Minimal mechanical wear, lower maintenance |

| Energy Efficiency | No energy savings during running | Improves energy efficiency during start and stop |

| Starting Torque | Reduced torque (~33%) at start | Adjustable torque control for smooth starting |

| Switching Noise | Mechanical switch causes noise and wear | Silent operation due to semiconductor controls |

Introduction to Motor Starting Methods

Star delta and soft starters are common motor starting methods designed to reduce inrush current and mechanical stress during startup. Star delta starters initially connect the motor in a star configuration, reducing voltage and current, then switch to delta for full power operation. Soft starters gradually ramp up voltage, providing smooth acceleration and better control over motor starting torque, protecting your equipment from electrical and mechanical shocks.

What is a Star Delta Starter?

A Star Delta Starter is an electrical motor starting method that reduces the initial current by initially connecting the motor windings in a star (Y) configuration, then switching to a delta (D) configuration for normal operation. This technique lowers the starting current to approximately one-third of the direct-on-line starting current, minimizing voltage drop and mechanical stress. Star Delta Starters are commonly used for three-phase induction motors rated between 5 to 50 HP in industrial applications to improve efficiency and extend motor lifespan.

Understanding Soft Starters

Soft starters control the voltage supply to your motor, gradually increasing it to reduce current surge and mechanical stress during startup. Unlike star-delta starters that switch connections from star to delta, soft starters use thyristor technology for smooth acceleration and deceleration. This precise control helps extend motor lifespan and improve operational efficiency in industrial applications.

Key Differences Between Star Delta and Soft Starter

Star delta starters reduce the initial starting current by switching the motor windings from a star to a delta configuration after startup, whereas soft starters control voltage supply smoothly to limit inrush current and torque. Star delta starters are mechanical and suited for large induction motors requiring reduced starting current, while soft starters offer precise control and protection for motors in applications needing smooth acceleration and deceleration. Your choice impacts motor performance, energy efficiency, and mechanical stress management depending on load requirements.

Advantages of Star Delta Starters

Star delta starters offer significant advantages such as reduced starting current, which limits electrical stress on motors and enhances power efficiency during startup. This method provides reliable mechanical and electrical simplicity, leading to lower maintenance costs and increased equipment lifespan. Additionally, star delta starters improve overall system stability by minimizing voltage drops in the power supply network during motor startup.

Benefits of Using Soft Starters

Soft starters provide precise voltage control during motor startup, reducing mechanical stress and electrical peak currents, which extends the lifespan of your equipment. They offer smooth acceleration and deceleration, minimizing wear on gears and belts compared to traditional star delta starters. Enhanced flexibility and energy efficiency make soft starters ideal for applications requiring frequent starts and stops.

Application Areas: Where to Use Each Starter

Star delta starters are ideal for reducing the starting current in large induction motors used in industrial applications such as pumps, compressors, and conveyors where mechanical stress reduction is crucial. Soft starters are preferred in applications requiring smooth acceleration and deceleration, such as HVAC systems, fans, and escalators, benefiting your equipment by minimizing electrical and mechanical wear. Choosing the right starter depends on the specific load characteristics and operational needs of your machinery.

Energy Efficiency Comparison

Star delta starters reduce initial inrush current by gradually switching the motor winding from star to delta configuration, lowering energy consumption during startup. Soft starters provide precise voltage control, minimizing electrical stress and achieving smoother acceleration with potentially higher energy efficiency under variable load conditions. Energy efficiency depends on specific application requirements, with soft starters often favored for complex operations demanding more refined control.

Cost Analysis: Star Delta vs Soft Starter

Star delta starters generally incur lower initial costs due to simpler design and fewer components, making them a cost-effective choice for reducing inrush current in squirrel cage induction motors. Soft starters, while having higher upfront costs because of advanced electronic controls and features like adjustable starting torque, deliver savings over time through reduced mechanical stress and improved process control. Maintenance expenses for star delta starters tend to be higher due to mechanical components, whereas soft starters offer lower long-term maintenance costs, enhancing overall cost efficiency.

Choosing the Right Starter for Your Application

Selecting between a star-delta starter and a soft starter depends on your motor's starting current requirements and control needs. Star-delta starters reduce initial inrush current by switching motor windings from star to delta configuration, suitable for simple, cost-effective applications with moderate starting torque. Soft starters offer precise voltage control and smooth acceleration, ideal for applications requiring reduced mechanical stress and customizable starting profiles to protect your equipment and extend its lifespan.

Star delta vs Soft starter Infographic

libmatt.com

libmatt.com