Inductive sensors detect metal objects by generating an electromagnetic field, making them ideal for proximity detection in industrial environments, while capacitive sensors sense changes in capacitance caused by both metallic and non-metallic materials, allowing Your system to detect a wider range of objects including liquids and plastics. Choosing the right sensor depends on the material and application requirements, with inductive sensors offering durability and capacitive sensors providing versatility.

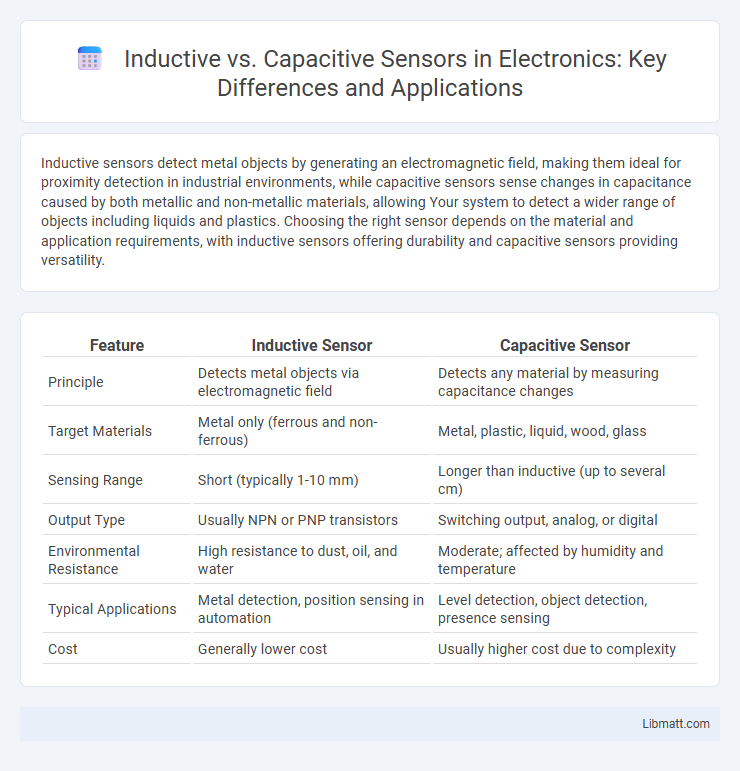

Table of Comparison

| Feature | Inductive Sensor | Capacitive Sensor |

|---|---|---|

| Principle | Detects metal objects via electromagnetic field | Detects any material by measuring capacitance changes |

| Target Materials | Metal only (ferrous and non-ferrous) | Metal, plastic, liquid, wood, glass |

| Sensing Range | Short (typically 1-10 mm) | Longer than inductive (up to several cm) |

| Output Type | Usually NPN or PNP transistors | Switching output, analog, or digital |

| Environmental Resistance | High resistance to dust, oil, and water | Moderate; affected by humidity and temperature |

| Typical Applications | Metal detection, position sensing in automation | Level detection, object detection, presence sensing |

| Cost | Generally lower cost | Usually higher cost due to complexity |

Introduction to Inductive and Capacitive Sensors

Inductive sensors detect metallic objects by generating an electromagnetic field and measuring changes caused by metal presence, making them highly reliable for metal detection and proximity sensing in industrial applications. Capacitive sensors detect changes in capacitance caused by the presence of both metallic and non-metallic materials, enabling versatile sensing of liquids, plastics, and granular materials. Both sensor types are integral to automation systems, providing precise and contactless detection for diverse manufacturing and control processes.

Basic Working Principles

Inductive sensors operate by generating an electromagnetic field to detect metallic objects through changes in inductance caused by the target's presence. Capacitive sensors measure variations in capacitance between the sensor and the target, allowing detection of both metallic and non-metallic materials based on changes in dielectric properties. These fundamental working principles define their applications in industrial automation, with inductive sensors suited for metal detection and capacitive sensors ideal for level sensing and material identification.

Key Differences Between Inductive and Capacitive Sensors

Inductive sensors detect metallic objects by generating an electromagnetic field, making them ideal for metal detection and high durability in harsh environments. Capacitive sensors sense changes in capacitance caused by both metallic and non-metallic materials, enabling detection of liquids, plastics, and more diverse substances. Understanding these key differences helps you choose the right sensor based on the target material and application requirements.

Typical Applications in Industry

Inductive sensors are widely used in manufacturing for detecting metal objects in automation systems, CNC machines, and assembly lines due to their robustness and precision in metal detection. Capacitive sensors excel in applications requiring the detection of non-metallic materials such as liquids, plastics, and powders, making them ideal for packaging, level sensing, and material handling industry processes. Your choice between inductive and capacitive sensors should consider the material properties and environmental conditions specific to your industrial application.

Advantages of Inductive Sensors

Inductive sensors offer high durability and reliability in harsh environments, as they are resistant to dirt, oil, and water, making them ideal for industrial automation. Their ability to detect metal objects with precise accuracy provides consistent performance and minimal maintenance requirements. Fast response time and long lifespan further enhance their suitability for high-speed manufacturing processes.

Advantages of Capacitive Sensors

Capacitive sensors offer the advantage of detecting both metallic and non-metallic objects, including liquids, plastics, and glass, providing versatile application options. They deliver high sensitivity and can measure changes in material properties like moisture content, making them ideal for level detection and quality control. Your systems benefit from their non-contact operation, durability, and resistance to dust, dirt, and corrosion, enhancing long-term reliability in diverse environments.

Limitations and Challenges

Inductive sensors are limited by their inability to detect non-metallic objects and have a shorter sensing range compared to capacitive sensors, making them less versatile in applications requiring detection of diverse materials. Capacitive sensors face challenges with sensitivity to environmental factors such as humidity, dust, and temperature variations, which can cause false readings or reduced accuracy. Your choice between these sensors should consider these limitations to ensure reliable performance in specific industrial or automation environments.

Choosing the Right Sensor for Your Application

Inductive sensors detect metal objects through electromagnetic fields, making them ideal for applications requiring precise metal detection and resistance to harsh environments. Capacitive sensors measure changes in capacitance to detect various materials, including liquids, plastics, and powders, offering versatility for diverse applications beyond metals. Choosing the right sensor depends on your target object's material and environmental conditions to ensure optimal performance and reliability.

Installation and Calibration Tips

Inductive sensors require precise alignment with metal targets during installation to ensure accurate detection, while capacitive sensors need careful positioning to avoid interference from non-metallic materials. Calibration for inductive sensors involves setting the sensing distance according to the metal object's size and material, whereas capacitive sensors demand sensitivity adjustments to differentiate between target objects and ambient conditions. Your optimal sensor performance depends on following manufacturer guidelines for mounting, wiring, and fine-tuning sensitivity based on the specific application environment.

Future Trends in Sensor Technology

Future trends in sensor technology highlight the integration of inductive and capacitive sensors with advanced IoT and AI systems, enabling smarter, real-time object detection and environmental monitoring. Innovations in materials for capacitive sensors improve sensitivity and miniaturization, while inductive sensors benefit from enhanced electromagnetic interference (EMI) shielding and energy efficiency. Emerging applications in autonomous vehicles and Industry 4.0 accelerate the development of hybrid sensor systems combining the strengths of both inductive and capacitive technologies.

Inductive vs Capacitive sensor Infographic

libmatt.com

libmatt.com