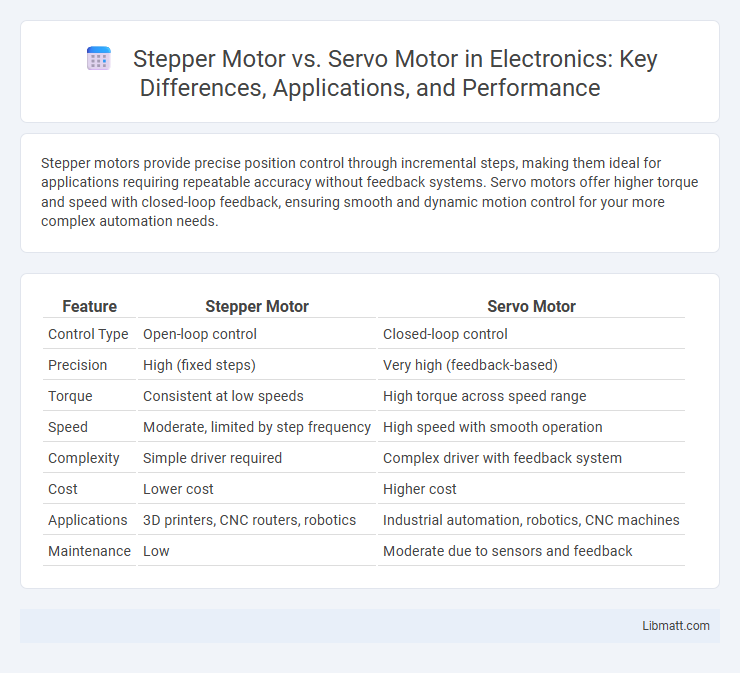

Stepper motors provide precise position control through incremental steps, making them ideal for applications requiring repeatable accuracy without feedback systems. Servo motors offer higher torque and speed with closed-loop feedback, ensuring smooth and dynamic motion control for your more complex automation needs.

Table of Comparison

| Feature | Stepper Motor | Servo Motor |

|---|---|---|

| Control Type | Open-loop control | Closed-loop control |

| Precision | High (fixed steps) | Very high (feedback-based) |

| Torque | Consistent at low speeds | High torque across speed range |

| Speed | Moderate, limited by step frequency | High speed with smooth operation |

| Complexity | Simple driver required | Complex driver with feedback system |

| Cost | Lower cost | Higher cost |

| Applications | 3D printers, CNC routers, robotics | Industrial automation, robotics, CNC machines |

| Maintenance | Low | Moderate due to sensors and feedback |

Introduction to Stepper and Servo Motors

Stepper motors operate by moving in precise, fixed increments, making them ideal for applications requiring accurate positioning without feedback control. Servo motors use a feedback system to provide continuous rotation control, offering high torque and speed with precise movement. Both types are essential in automation, with stepper motors favored for simplicity and servo motors for dynamic performance.

How Stepper Motors Work

Stepper motors operate by dividing a full rotation into equal steps, allowing precise control of angular position without feedback systems. They use multiple coils organized in phases that are energized in sequence to create a magnetic field, which causes the rotor to move step by step. This open-loop control makes stepper motors ideal for applications requiring accurate positioning, such as 3D printers and CNC machines.

How Servo Motors Operate

Servo motors operate through closed-loop control systems that continuously monitor position, velocity, and torque using feedback from encoders or resolvers. This precise feedback allows servo motors to adjust the input current to the motor windings in real-time, ensuring accurate movement and high torque at various speeds. Their ability to maintain position under load and execute complex motion profiles makes servo motors ideal for applications requiring precision and dynamic response.

Key Differences Between Stepper and Servo Motors

Stepper motors provide precise position control through incremental steps, making them ideal for applications requiring consistent and repeatable movements without feedback systems. Servo motors offer higher torque, speed, and dynamic response by using closed-loop feedback to adjust position and speed accurately. Choosing between stepper and servo motors depends on your specific requirements for precision, load capacity, and control complexity.

Accuracy and Precision Comparison

Stepper motors offer high positional accuracy through discrete step movements but can experience missed steps under heavy loads, affecting precision. Servo motors provide superior accuracy and precision by using closed-loop feedback systems, continuously correcting position errors for smooth, precise motion. In applications requiring consistent repeatability and fine control, servo motors typically outperform stepper motors in accuracy and precision.

Speed and Torque Characteristics

Stepper motors provide precise positioning with consistent torque at low to moderate speeds, but their torque significantly drops as speed increases, making them suitable for applications requiring accurate control at lower speeds. Servo motors deliver higher torque across a wide speed range, maintaining performance even at high speeds due to feedback control systems that adjust motor output dynamically. This makes servo motors ideal for applications demanding rapid acceleration, variable speed, and sustained torque under varying load conditions.

Control Systems and Complexity

Stepper motors operate with open-loop control systems, offering simplicity and precise position control without feedback, ideal for applications where cost-effective and straightforward control is sufficient. Servo motors utilize closed-loop control systems with sensors that provide continuous feedback, enabling complex, highly accurate movements and adaptive responses in demanding environments. Your choice depends on the required control complexity and precision, with stepper motors suited for basic tasks and servo motors for advanced, dynamic applications.

Cost and Maintenance Factors

Stepper motors generally have a lower initial cost compared to servo motors, making them a cost-effective choice for applications with budget constraints. Maintenance requirements for stepper motors are minimal due to their simpler design and lack of feedback systems, resulting in reduced downtime and servicing expenses. Servo motors, while more expensive upfront, often require regular maintenance of their feedback components and encoders, which can increase long-term operational costs.

Typical Applications for Each Motor Type

Stepper motors are commonly used in applications requiring precise position control at low to moderate speeds, such as 3D printers, CNC machines, and robotics for incremental movement tasks. Servo motors excel in dynamic applications needing high torque, accurate speed control, and rapid acceleration, including industrial automation, robotic arms, and camera gimbals. Your choice depends on whether the application demands continuous rotation with feedback (servo) or open-loop incremental positioning (stepper).

Choosing the Right Motor for Your Project

Selecting the right motor for your project depends on precision, speed, and control requirements. Stepper motors offer reliable position control and are ideal for applications needing consistent speed at moderate torque, such as 3D printers and CNC machines. Servo motors provide high torque, accuracy, and dynamic response, making them suitable for robotics and automation systems requiring precise movement and feedback.

Stepper Motor vs Servo Motor Infographic

libmatt.com

libmatt.com