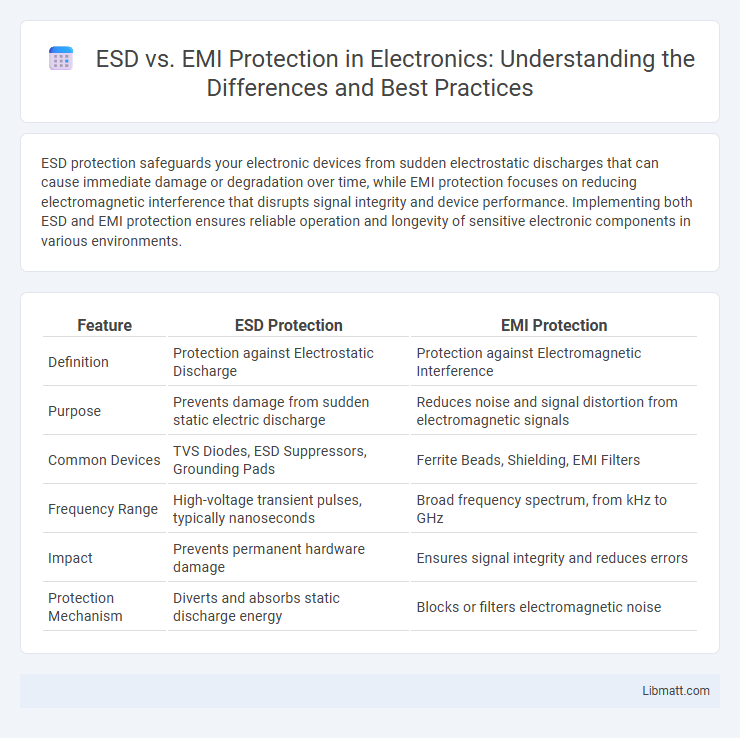

ESD protection safeguards your electronic devices from sudden electrostatic discharges that can cause immediate damage or degradation over time, while EMI protection focuses on reducing electromagnetic interference that disrupts signal integrity and device performance. Implementing both ESD and EMI protection ensures reliable operation and longevity of sensitive electronic components in various environments.

Table of Comparison

| Feature | ESD Protection | EMI Protection |

|---|---|---|

| Definition | Protection against Electrostatic Discharge | Protection against Electromagnetic Interference |

| Purpose | Prevents damage from sudden static electric discharge | Reduces noise and signal distortion from electromagnetic signals |

| Common Devices | TVS Diodes, ESD Suppressors, Grounding Pads | Ferrite Beads, Shielding, EMI Filters |

| Frequency Range | High-voltage transient pulses, typically nanoseconds | Broad frequency spectrum, from kHz to GHz |

| Impact | Prevents permanent hardware damage | Ensures signal integrity and reduces errors |

| Protection Mechanism | Diverts and absorbs static discharge energy | Blocks or filters electromagnetic noise |

Introduction to ESD and EMI Protection

Electrostatic Discharge (ESD) and Electromagnetic Interference (EMI) protection are crucial for maintaining the reliability and performance of electronic devices by preventing damage caused by static electricity and electromagnetic noise. ESD protection involves designing components and circuits to safely dissipate sudden high-voltage discharges, while EMI protection minimizes unwanted electromagnetic signals that can disrupt device operation. Your electronic systems require both ESD and EMI protection to ensure longevity and compliance with industry standards.

Understanding Electrostatic Discharge (ESD)

Electrostatic Discharge (ESD) refers to the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. ESD can damage sensitive electronic components by creating high voltage spikes that exceed the device's threshold. Protecting against ESD involves using specialized materials and circuit designs to safely dissipate static electricity and prevent harmful surges.

What is Electromagnetic Interference (EMI)?

Electromagnetic Interference (EMI) refers to the disturbance generated by external electromagnetic fields that disrupt the normal operation of electronic devices and systems. EMI can originate from natural sources such as lightning or man-made sources like radio transmitters, causing signal degradation, data loss, and equipment malfunctions. Effective EMI protection involves shielding, filtering, and grounding techniques to prevent electromagnetic noise from affecting sensitive electronics.

Key Differences Between ESD and EMI

ESD (Electrostatic Discharge) protection safeguards sensitive electronic components from sudden, high-voltage electrostatic shocks that can cause immediate damage or degradation. EMI (Electromagnetic Interference) protection, on the other hand, aims to reduce unwanted electromagnetic noise from disrupting signal integrity and device performance over time. Understanding these differences ensures your circuits maintain both reliability against static discharges and stable operation in noisy electromagnetic environments.

Common Sources of ESD and EMI in Electronics

Common sources of ESD in electronics include human body discharge, charged objects, and manufacturing processes, which can cause sudden voltage spikes damaging sensitive components. EMI originates from switching power supplies, radio frequency transmissions, and nearby electrical motors, leading to disturbances in signal integrity and device performance. Protecting your circuits requires addressing both ESD and EMI through appropriate shielding, grounding, and filtering techniques to ensure reliable operation.

Impact of ESD and EMI on Device Performance

Electrostatic discharge (ESD) can cause immediate damage or latent defects in semiconductor devices, leading to device failure or reduced lifespan, while electromagnetic interference (EMI) primarily degrades signal integrity and causes malfunctions in sensitive electronics. Proper ESD protection safeguards your device from sudden voltage spikes that can destroy internal components, whereas EMI shielding minimizes noise and crosstalk, ensuring stable and accurate operation. Implementing both ESD and EMI protection strategies is crucial for maintaining optimal device performance and reliability in complex electronic systems.

ESD Protection Techniques and Solutions

ESD protection techniques involve using components like transient voltage suppressor (TVS) diodes, metal-oxide varistors (MOVs), and specialized ESD protection ICs to safely dissipate electrostatic discharge events. Solutions often include PCB layout strategies such as grounding, shielding, and the use of series resistors or ferrite beads to reduce the risk of ESD damage. Effective ESD protection combines component-level devices with design-level methods to ensure system reliability in sensitive electronic circuits.

EMI Shielding and Mitigation Methods

EMI shielding involves the use of conductive or magnetic materials to block or reduce electromagnetic interference by reflecting or absorbing unwanted signals. Mitigation methods include the application of metal enclosures, conductive coatings, grounding techniques, and the integration of ferrite beads or EMI filters on cables and circuits. Effective EMI protection enhances signal integrity and prevents device malfunction in sensitive electronic systems.

Choosing the Right Protection: ESD vs EMI

Selecting the appropriate protection depends on the specific threat: Electrostatic Discharge (ESD) protection safeguards sensitive electronic components from sudden high-voltage static shocks, while Electromagnetic Interference (EMI) protection prevents noise and signal disturbances caused by external electromagnetic fields. ESD protection typically involves using transient voltage suppressors, specialized coatings, and grounding techniques, whereas EMI protection employs shielding, filtering, and careful PCB layout to minimize interference. Understanding the operating environment and the vulnerability of the device to either static discharge or electromagnetic noise is crucial for effective protection strategy implementation.

Best Practices for Integrated ESD and EMI Protection

Integrated ESD and EMI protection requires designing with low-capacitance components and proper grounding techniques to minimize signal distortion and ensure device reliability. Utilizing multi-layer PCB layouts with dedicated ground planes and implementing transient voltage suppression diodes can effectively mitigate both electrostatic discharge and electromagnetic interference. Selecting components with fast response times and placing them close to signal entry points enhances protection while maintaining high-frequency performance.

ESD vs EMI Protection Infographic

libmatt.com

libmatt.com