IR LED emits infrared light invisible to the human eye, primarily used in remote controls, night vision, and sensing applications, while UV LED emits ultraviolet light with higher energy, useful for sterilization, curing, and fluorescence detection. Choosing the right LED depends on your specific needs for wavelength, intensity, and application environment.

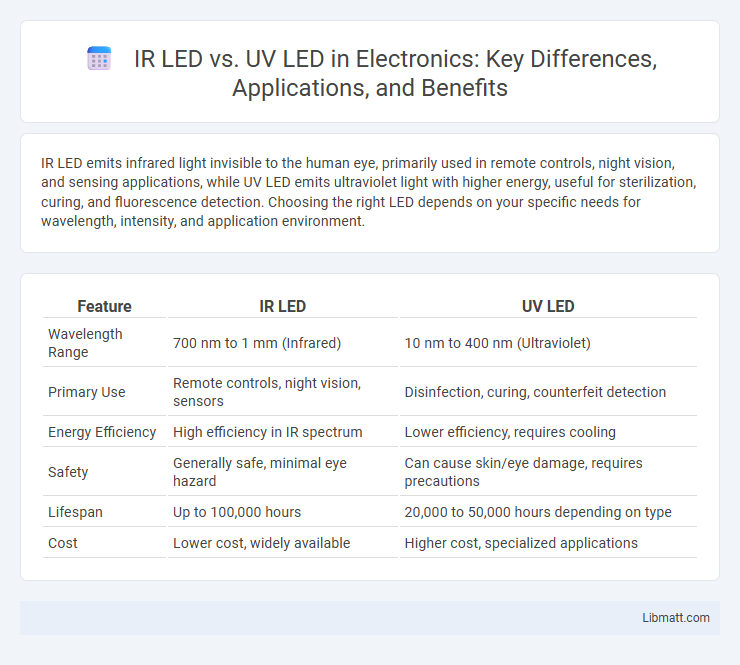

Table of Comparison

| Feature | IR LED | UV LED |

|---|---|---|

| Wavelength Range | 700 nm to 1 mm (Infrared) | 10 nm to 400 nm (Ultraviolet) |

| Primary Use | Remote controls, night vision, sensors | Disinfection, curing, counterfeit detection |

| Energy Efficiency | High efficiency in IR spectrum | Lower efficiency, requires cooling |

| Safety | Generally safe, minimal eye hazard | Can cause skin/eye damage, requires precautions |

| Lifespan | Up to 100,000 hours | 20,000 to 50,000 hours depending on type |

| Cost | Lower cost, widely available | Higher cost, specialized applications |

Introduction to IR and UV LEDs

IR LEDs emit infrared light with wavelengths typically between 700 nm and 1 mm, making them ideal for remote controls, night vision devices, and optical communication. UV LEDs produce ultraviolet light within the 100 nm to 400 nm range, widely used for sterilization, curing adhesives, and detecting counterfeit products. Your choice between IR and UV LEDs depends on the specific application and the wavelength needed for optimal performance.

Fundamental Differences Between IR and UV LEDs

IR LEDs emit infrared light with wavelengths typically ranging from 700 nm to 1 mm, primarily used for remote controls and night vision, while UV LEDs produce ultraviolet light between 10 nm and 400 nm, essential for sterilization and curing applications. The fundamental difference lies in their photon energy; UV LEDs emit higher-energy photons capable of breaking molecular bonds, whereas IR LEDs emit lower-energy photons suited for heat generation and sensing. Material composition also varies, with IR LEDs often made from gallium arsenide and UV LEDs from aluminum gallium nitride, influencing their emission spectra and application domains.

Wavelength Range and Light Spectrum

IR LEDs emit light in the infrared spectrum, typically within the wavelength range of 700 nm to 1,000 nm, which is invisible to the human eye but effective for night vision and remote sensing applications. UV LEDs operate within the ultraviolet spectrum, spanning approximately 200 nm to 400 nm, and are used for sterilization, fluorescence, and curing processes due to their higher energy light. Your choice between IR and UV LEDs depends on whether you need longer wavelength, low-energy light or shorter wavelength, high-energy UV light for specific tasks.

Applications of IR LEDs

IR LEDs are widely used in remote controls, night vision equipment, and optical communication systems due to their ability to emit infrared light invisible to the human eye. They play a crucial role in security cameras for low-light surveillance and in medical devices for non-invasive treatments and diagnostics. Industrial applications include gas sensing, flame detection, and proximity sensors, leveraging IR LEDs for accurate and reliable performance.

Applications of UV LEDs

UV LEDs are widely used in applications such as water purification, sterilization, and counterfeit detection due to their ability to emit ultraviolet light that destroys bacteria and viruses. They also play a critical role in curing adhesives and coatings in industrial processes, as well as in forensic analysis to detect bodily fluids or materials invisible to the naked eye. Your choice of UV LED can enhance performance in medical, security, and manufacturing fields where precise UV light emission is essential.

Efficiency and Energy Consumption

IR LEDs typically exhibit higher electrical-to-optical conversion efficiency compared to UV LEDs, resulting in lower energy consumption for equivalent output power. UV LEDs often require higher forward currents and voltage to achieve sufficient emission intensity, leading to increased energy usage and heat generation. Advances in semiconductor materials and chip design continue to improve the energy efficiency of both IR and UV LEDs, but IR LEDs currently maintain an advantage in energy-saving performance for most applications.

Safety Considerations: IR vs UV LEDs

IR LEDs emit longer wavelengths that penetrate deeper into tissues, posing less risk of surface skin damage but potential eye hazards like retinal burns if exposure is prolonged or intense. UV LEDs generate shorter wavelengths with higher energy, leading to risks of skin erythema, photokeratitis, and DNA damage due to ultraviolet radiation exposure. Proper protective measures, such as UV-blocking eyewear for UV LEDs and avoiding direct eye exposure for IR LEDs, are essential to minimize health risks.

Cost Comparison and Market Trends

IR LEDs generally cost less than UV LEDs due to simpler manufacturing processes and more widespread applications in consumer electronics and remote controls, driving mass production economies. UV LEDs, while pricier, are gaining market traction in sterilization, medical, and industrial sectors, prompting investment in research and development to reduce costs and improve efficiency. Market trends indicate a growing demand for UV LEDs driven by health and sanitation concerns, while IR LEDs maintain steady demand supported by established uses in security and sensing technologies.

Advantages and Disadvantages of Each Type

IR LEDs offer advantages such as deep penetration for applications like night vision and remote controls, with lower power consumption and longer lifespan. However, they have limited data transmission rates and are less effective for surface-level curing compared to UV LEDs. UV LEDs provide precise surface sterilization and rapid curing in industrial processes, but they typically consume more power, have shorter lifespans, and require careful handling due to potential health risks from UV exposure.

Choosing the Right LED: Key Factors to Consider

When choosing between IR LED and UV LED, consider wavelength requirements, as IR LEDs emit infrared light typically between 700 nm and 1 mm, while UV LEDs operate in the 100-400 nm range crucial for applications like sterilization and curing. Efficiency and power output vary, with IR LEDs generally offering higher energy efficiency for sensing and communication, whereas UV LEDs excel in disinfection and photolithography processes. Your decision should align with the specific application's spectral needs, durability, and safety considerations to optimize performance and functionality.

IR LED vs UV LED Infographic

libmatt.com

libmatt.com