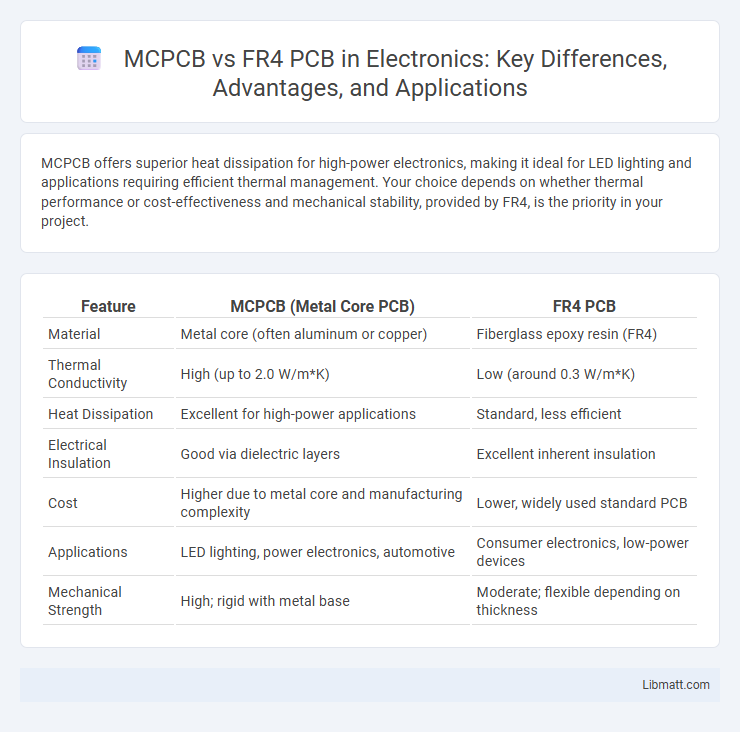

MCPCB offers superior heat dissipation for high-power electronics, making it ideal for LED lighting and applications requiring efficient thermal management. Your choice depends on whether thermal performance or cost-effectiveness and mechanical stability, provided by FR4, is the priority in your project.

Table of Comparison

| Feature | MCPCB (Metal Core PCB) | FR4 PCB |

|---|---|---|

| Material | Metal core (often aluminum or copper) | Fiberglass epoxy resin (FR4) |

| Thermal Conductivity | High (up to 2.0 W/m*K) | Low (around 0.3 W/m*K) |

| Heat Dissipation | Excellent for high-power applications | Standard, less efficient |

| Electrical Insulation | Good via dielectric layers | Excellent inherent insulation |

| Cost | Higher due to metal core and manufacturing complexity | Lower, widely used standard PCB |

| Applications | LED lighting, power electronics, automotive | Consumer electronics, low-power devices |

| Mechanical Strength | High; rigid with metal base | Moderate; flexible depending on thickness |

Introduction to MCPCB and FR4 PCB

MCPCB (Metal Core Printed Circuit Board) features a metal base, typically aluminum or copper, providing superior heat dissipation ideal for high-power applications like LED lighting and power modules. FR4 PCB consists of a fiberglass-reinforced epoxy laminate, known for its lightweight, cost-effectiveness, and versatility across standard electronic circuits. Understanding the key differences between MCPCB and FR4 PCB helps you select the right board based on thermal management and mechanical requirements.

Core Material Differences

MCPCB (Metal Core Printed Circuit Board) uses a metal core, typically aluminum or copper, providing superior heat dissipation for high-power applications. FR4 PCB features a core made of woven fiberglass epoxy resin, offering good electrical insulation but lower thermal conductivity. The core material difference directly impacts thermal management, mechanical stability, and application suitability.

Thermal Management Capabilities

MCPCB (Metal Core Printed Circuit Board) offers superior thermal management capabilities compared to FR4 PCB due to its metal core, typically aluminum or copper, which efficiently dissipates heat away from high-power components. FR4 PCBs rely on a fiberglass epoxy substrate with limited thermal conductivity, making them less effective in heat dissipation and prone to overheating in power-intensive applications. The enhanced heat dissipation of MCPCBs extends component lifespan and improves overall performance in LED lighting, power electronics, and automotive industries.

Electrical Performance Comparison

MCPCB offers superior electrical performance with enhanced thermal management, reducing resistance and improving current carrying capacity compared to FR4 PCB. Its metal core efficiently dissipates heat, minimizing signal loss and ensuring stable operation in high-power applications. Your choice of MCPCB can significantly improve reliability and efficiency in circuits demanding better electrical conductivity and heat control.

Mechanical Strength and Durability

MCPCBs (Metal Core Printed Circuit Boards) offer superior mechanical strength and durability compared to FR4 PCBs due to their metal base, typically aluminum or copper, which provides enhanced structural support and better thermal management. FR4 PCBs, made from fiberglass epoxy resin, are less robust under high stress or thermal cycling, making them more susceptible to cracking or warping. These characteristics make MCPCBs ideal for applications requiring high mechanical reliability and thermal endurance.

Application Areas and Industry Use

MCPCBs excel in high-power LED lighting, automotive electronics, and power supplies due to their superior thermal management and high heat dissipation capabilities. FR4 PCBs dominate consumer electronics, computing devices, and low-frequency communication equipment, prized for cost-effectiveness and versatile structural integrity. Industrial automation and telecommunications sectors leverage MCPCB for heat-sensitive components, while FR4 remains the standard in general-purpose circuit boards and prototyping.

Manufacturing Processes

MCPCB manufacturing involves layering a metal base, typically aluminum or copper, with dielectric insulation and a copper circuit layer, enhancing heat dissipation for high-power applications. FR4 PCB production uses woven fiberglass cloth with epoxy resin to form a solid laminate, supporting multiple layers of copper traces for general electronics. Your choice impacts thermal management and production complexity based on the manufacturing differences between MCPCB and FR4 PCB.

Cost Analysis: MCPCB vs FR4 PCB

MCPCB (Metal Core Printed Circuit Board) generally incurs higher manufacturing costs compared to FR4 PCB due to its specialized metal core materials like aluminum or copper, which enhance thermal conductivity. FR4 PCBs are more cost-effective for standard electronic applications because of their widespread availability and simpler fabrication process using fiberglass epoxy resin. While MCPCBs justify their premium price through superior heat dissipation capabilities essential for high-power LED and power electronics, FR4 PCBs remain budget-friendly options for most general-purpose circuits.

Design Flexibility and Limitations

MCPCB offers superior thermal management through its metal core but has limited design flexibility compared to FR4 PCB, restricting complex circuit layouts and multi-layer configurations. FR4 PCB provides greater design versatility, supporting intricate signal routing and diverse component placements, making it suitable for complex electronic applications. Your choice depends on whether thermal conductivity or intricate design requirements take precedence in your project.

Choosing the Right PCB for Your Project

Selecting between MCPCB and FR4 PCB depends on your project's thermal management and performance needs. MCPCB (Metal Core Printed Circuit Board) excels in dissipating heat, making it ideal for high-power LED and automotive applications, while FR4 PCB offers cost-effective insulation and is suitable for general electronic devices with moderate thermal requirements. Assessing factors such as operating temperature, electrical insulation, mechanical strength, and budget ensures the right PCB choice for optimized functionality and reliability.

MCPCB vs FR4 PCB Infographic

libmatt.com

libmatt.com