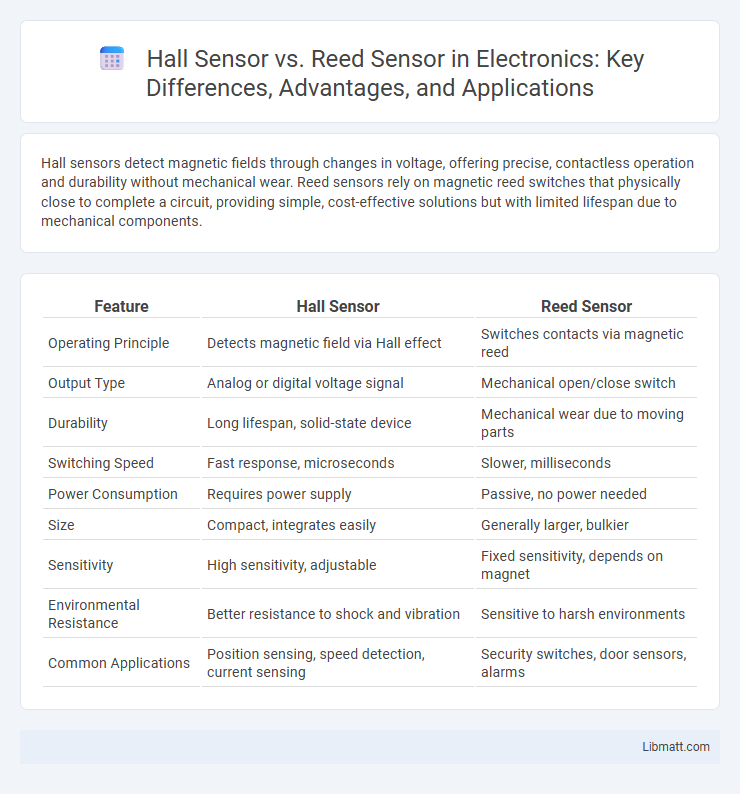

Hall sensors detect magnetic fields through changes in voltage, offering precise, contactless operation and durability without mechanical wear. Reed sensors rely on magnetic reed switches that physically close to complete a circuit, providing simple, cost-effective solutions but with limited lifespan due to mechanical components.

Table of Comparison

| Feature | Hall Sensor | Reed Sensor |

|---|---|---|

| Operating Principle | Detects magnetic field via Hall effect | Switches contacts via magnetic reed |

| Output Type | Analog or digital voltage signal | Mechanical open/close switch |

| Durability | Long lifespan, solid-state device | Mechanical wear due to moving parts |

| Switching Speed | Fast response, microseconds | Slower, milliseconds |

| Power Consumption | Requires power supply | Passive, no power needed |

| Size | Compact, integrates easily | Generally larger, bulkier |

| Sensitivity | High sensitivity, adjustable | Fixed sensitivity, depends on magnet |

| Environmental Resistance | Better resistance to shock and vibration | Sensitive to harsh environments |

| Common Applications | Position sensing, speed detection, current sensing | Security switches, door sensors, alarms |

Introduction to Hall Sensors and Reed Sensors

Hall sensors operate based on the Hall effect, detecting magnetic fields through voltage changes induced in a conductor, while reed sensors consist of two ferromagnetic blades sealed in a glass tube that close or open in response to magnetic presence. Hall sensors offer precise, contactless magnetic field measurement with solid-state reliability, making them suitable for various applications such as speed detection and current sensing. Reed sensors provide simple, mechanical switching action commonly used for position sensing and security systems due to their low cost and ease of integration.

Basic Operating Principles

Hall sensors detect magnetic fields through the Hall effect, producing a voltage proportional to the magnetic flux density, enabling non-contact position and speed sensing. Reed sensors rely on two ferromagnetic reed blades sealed in a glass tube, which close or open an electrical circuit when exposed to a magnetic field, providing a simple on/off switch operation. Hall sensors support continuous and analog measurements, while reed sensors function as discrete switches triggered by proximity to a magnet.

Key Differences Between Hall and Reed Sensors

Hall sensors utilize the Hall effect to detect magnetic fields with high sensitivity and precision, while reed sensors operate through magnetic reed switches that physically open or close when exposed to a magnetic field. Hall sensors offer faster response times, longer life spans, and better durability in harsh environments compared to reed sensors, which are simpler and cost-effective but have moving parts prone to wear. The key differences lie in their sensing mechanisms, response speed, durability, and typical applications in automation and security systems.

Sensitivity and Response Time Comparison

Hall sensors exhibit higher sensitivity due to their ability to detect minute changes in magnetic fields, enabling accurate measurement at low magnetic flux densities. Reed sensors offer faster response times, often in the microsecond range, making them ideal for applications requiring swift switching. The choice between these sensors depends on whether sensitivity to small magnetic variations or rapid response is paramount for the application.

Applications in Automotive and Industrial Fields

Hall sensors are widely utilized in automotive applications for precise position sensing, speed detection, and current measurement, often found in anti-lock braking systems (ABS), throttle position sensing, and electric motor control. Reed sensors are commonly employed in industrial settings for limit switching, fluid level detection, and security systems due to their reliability in harsh environments and simplicity in detecting magnetic fields. Both sensors complement each other in automotive and industrial sectors, where Hall sensors offer higher durability and sensitivity while reed sensors provide cost-effective, straightforward solutions.

Durability and Reliability Factors

Hall sensors offer superior durability and reliability compared to reed sensors due to their solid-state construction, which eliminates mechanical contacts prone to wear and failure. Reed sensors rely on a pair of ferromagnetic reeds enclosed in a glass tube, making them vulnerable to contact degradation and breakage under vibration or shock. You benefit from Hall sensors' consistent performance in harsh environments, providing longer service life and reduced maintenance needs.

Power Consumption and Supply Requirements

Hall sensors typically require a continuous power supply, consuming more power due to their active electronic components, which makes them ideal for applications needing precise and continuous position sensing. Reed sensors are passive devices, drawing power only when their magnetic contacts close, resulting in very low power consumption and suitability for battery-operated or energy-sensitive environments. Your choice between these sensors depends heavily on power availability and the specific demands of your application's energy efficiency.

Installation and Maintenance Considerations

Hall sensors require precise alignment and a stable power supply for optimal performance, often necessitating careful mounting near a magnet, which simplifies maintenance through non-contact sensing and reduces wear. Reed sensors involve simpler installation with two moving contacts enclosed in a glass capsule that close or open circuits in response to magnetic fields, but they are susceptible to mechanical fatigue and may require periodic replacement. The non-contact nature of Hall sensors offers longer lifespan and minimal maintenance, whereas reed sensors, though cost-effective, demand more frequent inspections due to potential contact degradation.

Cost Analysis: Hall Sensor vs Reed Sensor

Hall sensors generally have a higher upfront cost compared to reed sensors due to their semiconductor components and advanced technology. Reed sensors, being simpler magnetic switches, offer a lower initial price and are cost-effective for basic applications requiring reliable switching with minimal power consumption. Your decision should weigh the total cost of ownership, including durability and maintenance, as Hall sensors often provide longer lifespan and greater precision, potentially reducing replacement frequency and long-term expenses.

Choosing the Right Sensor for Your Needs

Hall sensors provide precise, contactless magnetic field detection with higher durability and faster response times, making them ideal for applications requiring accurate position or speed measurements. Reed sensors operate through a simple mechanical switch activated by a magnetic field, offering cost-effective solutions for basic on/off detection in less demanding environments. Your choice depends on the required sensitivity, environmental conditions, and whether you prioritize longevity or budget constraints.

Hall Sensor vs Reed Sensor Infographic

libmatt.com

libmatt.com