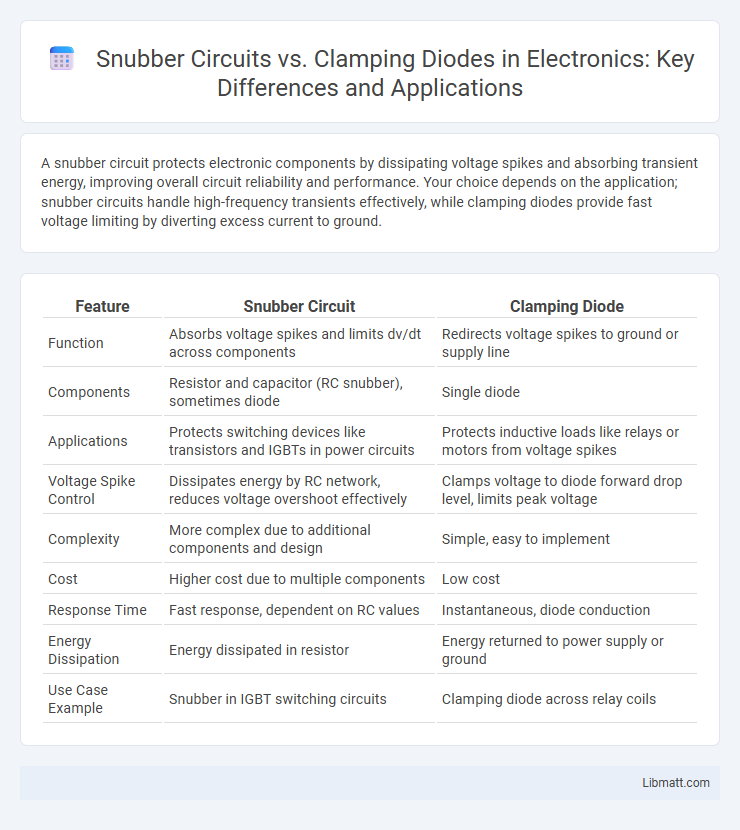

A snubber circuit protects electronic components by dissipating voltage spikes and absorbing transient energy, improving overall circuit reliability and performance. Your choice depends on the application; snubber circuits handle high-frequency transients effectively, while clamping diodes provide fast voltage limiting by diverting excess current to ground.

Table of Comparison

| Feature | Snubber Circuit | Clamping Diode |

|---|---|---|

| Function | Absorbs voltage spikes and limits dv/dt across components | Redirects voltage spikes to ground or supply line |

| Components | Resistor and capacitor (RC snubber), sometimes diode | Single diode |

| Applications | Protects switching devices like transistors and IGBTs in power circuits | Protects inductive loads like relays or motors from voltage spikes |

| Voltage Spike Control | Dissipates energy by RC network, reduces voltage overshoot effectively | Clamps voltage to diode forward drop level, limits peak voltage |

| Complexity | More complex due to additional components and design | Simple, easy to implement |

| Cost | Higher cost due to multiple components | Low cost |

| Response Time | Fast response, dependent on RC values | Instantaneous, diode conduction |

| Energy Dissipation | Energy dissipated in resistor | Energy returned to power supply or ground |

| Use Case Example | Snubber in IGBT switching circuits | Clamping diode across relay coils |

Introduction to Snubber Circuits and Clamping Diodes

Snubber circuits and clamping diodes both protect electronic components from voltage spikes, but they operate differently in managing transient energy. Snubber circuits use resistors and capacitors to absorb and dissipate excess energy, reducing voltage overshoot and ringing in switching devices. Clamping diodes, on the other hand, redirect voltage spikes by providing a low-resistance path, instantly clamping the voltage to a safe level, protecting your circuits from damage.

Fundamental Function of Snubber Circuits

Snubber circuits primarily protect semiconductor devices by absorbing voltage spikes and limiting surge currents during switching events, thereby preventing damage caused by inductive loads. They consist of resistors, capacitors, and sometimes diodes, designed to control the rate of voltage change (dV/dt) and dissipate transient energy safely. Unlike clamping diodes that provide a simple path for current to suppress voltage spikes, snubber circuits offer enhanced control over switching transients and improve overall circuit reliability.

Core Operation of Clamping Diodes

Clamping diodes operate by redirecting voltage spikes to a safe reference level, protecting sensitive components from transient overvoltages through rapid conduction during voltage excursions beyond a predetermined threshold. In contrast to snubber circuits that utilize resistors and capacitors to absorb and dissipate energy, clamping diodes provide a simpler, faster response by limiting voltage to a diode's forward voltage drop. Understanding the core operation of clamping diodes helps you design efficient protection schemes in power electronics and switching circuits.

Key Differences Between Snubber Circuits and Clamping Diodes

Snubber circuits and clamping diodes both protect electronic components from voltage spikes but differ in design and application. Snubber circuits typically use resistors and capacitors to absorb and dissipate energy, reducing switching transients, whereas clamping diodes redirect excess voltage to a safe path, preventing overvoltage damage. Understanding these key differences helps optimize your circuit protection strategy for improved performance and longevity.

Advantages of Using Snubber Circuits

Snubber circuits effectively protect power electronic devices by absorbing voltage spikes and reducing switching transients, enhancing overall circuit reliability and longevity. They provide controlled energy dissipation and improve switching performance by minimizing electromagnetic interference (EMI) and voltage stress on components. Your systems benefit from precise snubber design, which optimizes efficiency and prevents damage from sudden voltage variations more effectively than clamping diodes.

Benefits of Clamping Diodes in Electronic Circuits

Clamping diodes protect sensitive electronic components by limiting voltage spikes, ensuring circuit stability and preventing damage from transient overvoltages. They provide fast response times and reliable voltage clamping, enhancing the durability and performance of power electronics and switching devices. Your circuits benefit from improved noise suppression and extended component lifespan due to the diode's ability to absorb and redirect excess energy efficiently.

Application Scenarios for Snubber Circuits

Snubber circuits are primarily applied in power electronics to protect switching devices such as transistors and thyristors from voltage spikes caused by inductive loads during switching. They are commonly used in motor drives, DC-DC converters, and inverter circuits to suppress transient voltages and reduce electromagnetic interference (EMI). Unlike clamping diodes, which provide a simple path for voltage spikes, snubber circuits offer controlled dissipation of energy, enhancing reliability in high-frequency switching applications.

Typical Uses of Clamping Diodes

Clamping diodes are typically used to protect sensitive electronic components by limiting voltage spikes in inductive loads such as relays, motors, and solenoids. They prevent voltage transients from damaging semiconductor devices by redirecting the energy back to the power supply or ground, thus ensuring circuit reliability. Common applications include flyback diode configurations in DC motor drives and relay coil protection in automotive and industrial control systems.

Design Considerations for Snubber Circuits vs Clamping Diodes

Design considerations for snubber circuits focus on controlling voltage transients and dissipating energy using resistors and capacitors, requiring careful selection of component values to match the load and switching frequency. Clamping diodes prioritize rapid voltage clamp near the supply level to prevent overvoltage by providing a low-impedance path for inductive kickback, with emphasis on diode speed, reverse recovery time, and voltage rating. Your choice depends on the trade-offs between energy dissipation, circuit complexity, and response time needed for protecting switching devices.

Choosing Between Snubber Circuits and Clamping Diodes: Summary

Choosing between snubber circuits and clamping diodes depends on the specific application and voltage transient requirements; snubber circuits effectively control voltage spikes and dampen oscillations in inductive loads, while clamping diodes primarily protect against reverse voltage by providing a low-resistance path for inductive kickback. Your decision should factor in the complexity, cost, and response speed needed, with snubber circuits offering more precise waveform control and clamping diodes providing simpler, cost-effective protection. Selecting the optimal protection approach enhances circuit reliability and extends component lifespan.

Snubber circuit vs Clamping diode Infographic

libmatt.com

libmatt.com