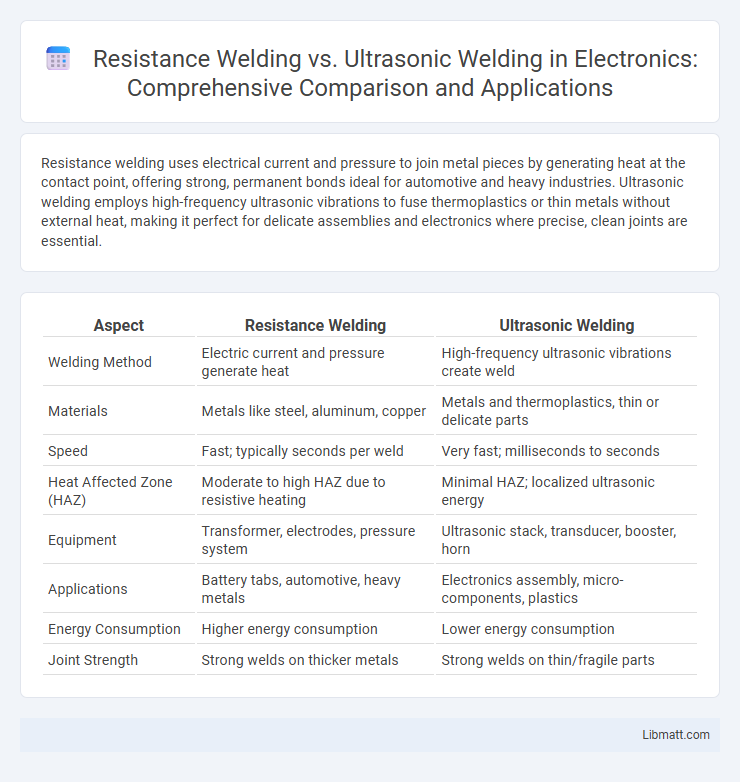

Resistance welding uses electrical current and pressure to join metal pieces by generating heat at the contact point, offering strong, permanent bonds ideal for automotive and heavy industries. Ultrasonic welding employs high-frequency ultrasonic vibrations to fuse thermoplastics or thin metals without external heat, making it perfect for delicate assemblies and electronics where precise, clean joints are essential.

Table of Comparison

| Aspect | Resistance Welding | Ultrasonic Welding |

|---|---|---|

| Welding Method | Electric current and pressure generate heat | High-frequency ultrasonic vibrations create weld |

| Materials | Metals like steel, aluminum, copper | Metals and thermoplastics, thin or delicate parts |

| Speed | Fast; typically seconds per weld | Very fast; milliseconds to seconds |

| Heat Affected Zone (HAZ) | Moderate to high HAZ due to resistive heating | Minimal HAZ; localized ultrasonic energy |

| Equipment | Transformer, electrodes, pressure system | Ultrasonic stack, transducer, booster, horn |

| Applications | Battery tabs, automotive, heavy metals | Electronics assembly, micro-components, plastics |

| Energy Consumption | Higher energy consumption | Lower energy consumption |

| Joint Strength | Strong welds on thicker metals | Strong welds on thin/fragile parts |

Introduction to Resistance Welding and Ultrasonic Welding

Resistance welding uses electric current to generate heat through the resistance of metal surfaces, creating a strong bond between materials, commonly used for joining sheet metals. Ultrasonic welding employs high-frequency mechanical vibrations to fuse plastic or metal parts without melting, ideal for delicate components and thermoplastics. Your choice depends on material type, precision, and application requirements, with resistance welding favored for metals and ultrasonic welding preferred for plastics and thin materials.

Principles of Resistance Welding

Resistance welding operates on the principle of generating heat through the electrical resistance of materials at the interface of the parts being joined. When electric current passes through the materials under pressure, localized heating occurs, causing the metal surfaces to melt and fuse together. This process results in a strong, permanent bond, commonly used in manufacturing industries for joining metals like steel and aluminum.

Principles of Ultrasonic Welding

Ultrasonic welding operates by applying high-frequency ultrasonic vibrations to materials held together under pressure, causing localized heat through friction that bonds the surfaces without melting the entire workpiece. This process is ideal for joining dissimilar metals, plastics, and delicate components with precision and minimal thermal distortion. Unlike resistance welding, which relies on electrical resistance and heat generation, ultrasonic welding emphasizes mechanical vibrations to create strong, clean joints rapidly and efficiently.

Key Differences Between Resistance and Ultrasonic Welding

Resistance welding uses electrical current to generate heat and fuse metal parts, ideal for thicker materials and high-strength joints, while ultrasonic welding employs high-frequency ultrasonic vibrations to join plastics or thin metals with precision and speed. The process temperature in resistance welding is significantly higher, often exceeding 1000degC, whereas ultrasonic welding remains below the melting point, preserving material integrity. Your choice between these methods depends on material type, thickness, joint strength requirements, and production speed.

Materials Suitable for Resistance Welding

Resistance welding is highly effective for joining conductive metals such as steel, stainless steel, aluminum, and copper alloys due to their excellent electrical conductivity and heat generation properties during the welding process. This method is particularly suitable for thin sheets and wire materials, making it prevalent in automotive, aerospace, and electronics manufacturing where strong, precise welds are required. Metals with high electrical resistance are preferred in resistance welding as they allow efficient heat buildup at the weld interface, ensuring consistent fusion and joint strength.

Materials Suitable for Ultrasonic Welding

Ultrasonic welding is highly effective for joining thermoplastics such as ABS, polycarbonate, and polypropylene, as well as thin metal foils including aluminum and copper. This method excels in bonding dissimilar materials without additives or adhesives, making it ideal for delicate components in electronics and medical devices. Resistance welding, by contrast, is more suited for heavier gauge metals but lacks versatility with plastics and fine materials where ultrasonic welding excels.

Applications of Resistance Welding

Resistance welding is widely used in automotive manufacturing for joining sheet metals and components due to its speed and reliability in producing strong welds. It is also essential in electrical industry applications, such as battery pack assembly and terminal connections, where precise control over heat and pressure ensures consistent conductivity. Your production process benefits from resistance welding's ability to join dissimilar metals efficiently in mass production environments.

Applications of Ultrasonic Welding

Ultrasonic welding is widely applied in the electronics industry for assembling delicate components such as sensors, microcircuits, and medical devices due to its precision and low thermal impact. It is also prevalent in the automotive sector for joining thermoplastic parts and lightweight materials, improving fuel efficiency through weight reduction. Furthermore, ultrasonic welding is essential in packaging applications, especially for sealing blister packs and containers made from thin plastic films.

Advantages and Limitations of Each Welding Method

Resistance welding offers advantages such as fast processing, strong and consistent joints, and minimal need for filler materials, making it ideal for metal fabrication. Its limitations include high energy consumption and sensitivity to material thickness and surface condition, which can affect weld quality. Ultrasonic welding provides precise bonding of dissimilar materials, low thermal distortion, and suitability for delicate components, but its limitations involve restrictions to thin materials and lower joint strength compared to resistance welding, which you should consider based on your project requirements.

Choosing the Right Welding Technique for Your Application

Resistance welding excels in joining metals with high electrical conductivity and thickness, offering strong, durable bonds ideal for automotive and heavy manufacturing applications. Ultrasonic welding is preferred for delicate materials like plastics and thin metals, delivering precise, heat-free joins suitable for electronics and medical devices. Selecting the right welding technique depends on material type, thickness, production speed, and the required bond strength for the specific application.

Resistance welding vs Ultrasonic welding Infographic

libmatt.com

libmatt.com