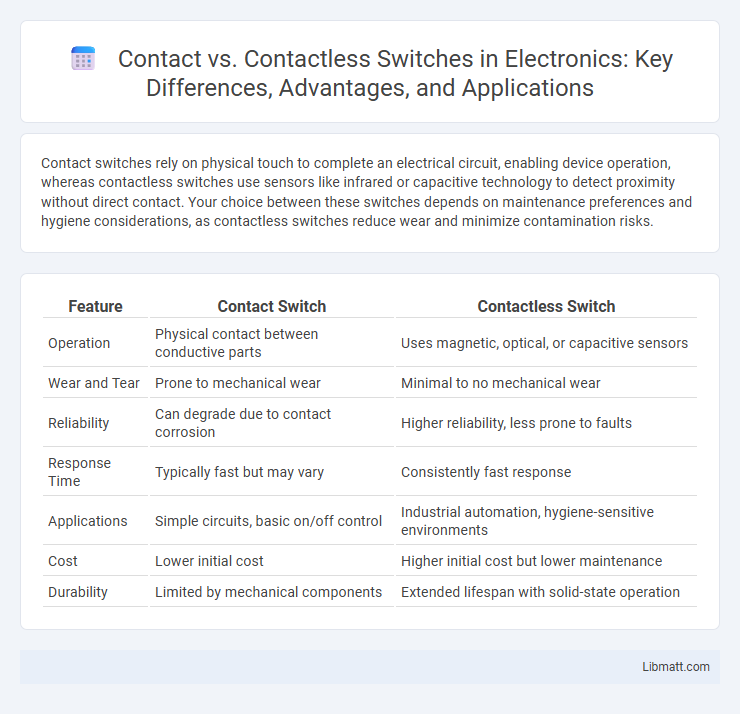

Contact switches rely on physical touch to complete an electrical circuit, enabling device operation, whereas contactless switches use sensors like infrared or capacitive technology to detect proximity without direct contact. Your choice between these switches depends on maintenance preferences and hygiene considerations, as contactless switches reduce wear and minimize contamination risks.

Table of Comparison

| Feature | Contact Switch | Contactless Switch |

|---|---|---|

| Operation | Physical contact between conductive parts | Uses magnetic, optical, or capacitive sensors |

| Wear and Tear | Prone to mechanical wear | Minimal to no mechanical wear |

| Reliability | Can degrade due to contact corrosion | Higher reliability, less prone to faults |

| Response Time | Typically fast but may vary | Consistently fast response |

| Applications | Simple circuits, basic on/off control | Industrial automation, hygiene-sensitive environments |

| Cost | Lower initial cost | Higher initial cost but lower maintenance |

| Durability | Limited by mechanical components | Extended lifespan with solid-state operation |

Introduction to Contact and Contactless Switches

Contact switches operate by physically closing or opening an electrical circuit through mechanical means, ensuring direct electrical contact and reliable switching performance. Contactless switches use technologies like capacitive, inductive, or optical sensing to detect presence or motion without any physical interaction, providing enhanced durability and reduced wear. Choosing between contact and contactless switches depends on your application's need for longevity, maintenance, and response speed.

Understanding Contact Switch Technology

Contact switch technology relies on physical interaction where metal components touch to complete an electrical circuit, ensuring reliable signal transmission. Contactless switches use magnetic, capacitive, or optical sensors to detect user input without physical contact, reducing wear and enhancing durability. Understanding these differences helps you select the ideal switch type for applications requiring either tactile feedback or long-term maintenance-free operation.

Exploring Contactless Switch Mechanisms

Contactless switch mechanisms utilize magnetic, capacitive, or optical sensors to detect user inputs without physical contact, improving durability and hygiene by eliminating mechanical wear and contamination risks. These switches offer faster response times and greater reliability compared to traditional contact switches, which rely on physical metal contacts that can degrade over time. Understanding your needs for maintenance-free operation and enhanced user experience can help you choose the ideal switch technology for modern electronic applications.

Key Differences: Contact vs Contactless Switches

Contact switches operate through physical touch between conductive components to complete an electrical circuit, while contactless switches use magnetic, capacitive, or optical sensors to detect activation without direct physical contact. Contact switches typically experience wear and tear due to mechanical movement, whereas contactless switches offer longer durability and reduced maintenance by eliminating physical friction. Response time and sensitivity in contactless switches are generally higher, enabling more precise and faster control in industrial and consumer applications.

Advantages of Contact Switches

Contact switches offer reliable and precise operation due to direct physical connection between components, ensuring consistent signal transmission and minimal electrical noise. They provide tactile feedback, enhancing user control and confidence during interaction. Your devices benefit from simpler circuitry design and lower cost compared to contactless alternatives, making them ideal for many standard applications.

Benefits of Contactless Switches

Contactless switches offer increased durability by eliminating physical wear and tear, ensuring longer lifespan and consistent performance. These switches provide enhanced reliability and faster response times, making them ideal for high-frequency or critical applications. By reducing mechanical failure risks, your systems gain improved safety and lower maintenance costs.

Common Applications for Contact Switches

Contact switches are commonly used in industrial machinery, home appliances, and automotive controls due to their reliable mechanical operation and distinct on/off states. These switches excel in applications requiring precise tactile feedback and durability, such as limit switches, pushbuttons, and toggle switches. Their widespread use in control panels and safety systems highlights their dependable performance in environments with frequent mechanical engagement.

Typical Uses for Contactless Switches

Contactless switches are typically used in environments demanding high durability, hygiene, and reliability, such as medical devices, industrial automation, and consumer electronics. They utilize technologies like capacitive, inductive, or optical sensing, eliminating mechanical wear and minimizing the risk of contamination. Your applications benefit from contactless switches by ensuring longer lifespan and reduced maintenance needs in harsh or clean environments.

Factors to Consider When Choosing Between Switch Types

Choosing between contact and contactless switches depends on factors such as durability requirements, environmental conditions, and maintenance preferences. Contact switches are preferred for their simplicity and cost-effectiveness in low-dust environments, while contactless switches offer longer lifespan and reliability in harsh or high-vibration settings by eliminating physical wear. Electrical performance, sensitivity, and installation complexity also influence the selection to ensure optimal functionality in specific applications.

Future Trends in Switching Technology

Contactless switches are rapidly advancing with integrated sensor technology and wireless communication capabilities, offering enhanced durability and reduced maintenance compared to traditional contact switches. Future trends highlight the adoption of IoT-enabled smart switches that provide real-time data and remote control, improving automation across various industries. Your choice of switching technology will increasingly favor contactless solutions due to their reliability and compatibility with emerging smart system infrastructures.

Contact vs Contactless Switch Infographic

libmatt.com

libmatt.com