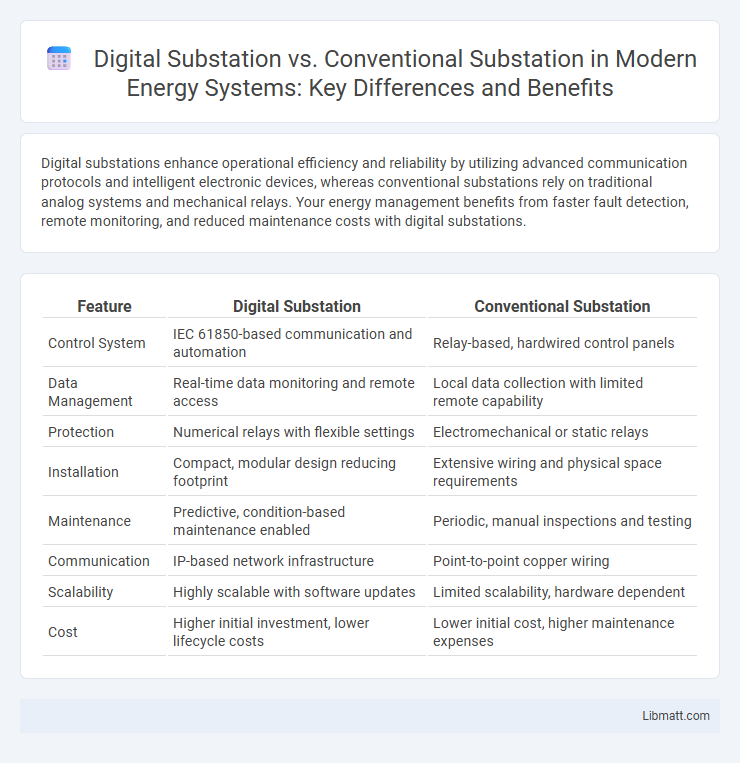

Digital substations enhance operational efficiency and reliability by utilizing advanced communication protocols and intelligent electronic devices, whereas conventional substations rely on traditional analog systems and mechanical relays. Your energy management benefits from faster fault detection, remote monitoring, and reduced maintenance costs with digital substations.

Table of Comparison

| Feature | Digital Substation | Conventional Substation |

|---|---|---|

| Control System | IEC 61850-based communication and automation | Relay-based, hardwired control panels |

| Data Management | Real-time data monitoring and remote access | Local data collection with limited remote capability |

| Protection | Numerical relays with flexible settings | Electromechanical or static relays |

| Installation | Compact, modular design reducing footprint | Extensive wiring and physical space requirements |

| Maintenance | Predictive, condition-based maintenance enabled | Periodic, manual inspections and testing |

| Communication | IP-based network infrastructure | Point-to-point copper wiring |

| Scalability | Highly scalable with software updates | Limited scalability, hardware dependent |

| Cost | Higher initial investment, lower lifecycle costs | Lower initial cost, higher maintenance expenses |

Introduction to Substation Technologies

Digital substations utilize advanced communication protocols like IEC 61850 to enable real-time data exchange and remote monitoring, enhancing operational efficiency and reliability. Conventional substations rely on hardwired control and analog instruments, limiting automation and dynamic data processing capabilities. Transitioning to digital substation technologies facilitates improved fault detection, protection schemes, and integration with smart grid systems.

What is a Conventional Substation?

A conventional substation uses electromechanical relays and analog devices to control and protect electrical power systems, relying on hard-wired connections for communication and monitoring. These substations typically feature separate control panels and rely on physical wiring for signal transmission, leading to complex infrastructure and slower response times. Maintenance and upgrades tend to be labor-intensive due to the lack of digital integration and standardized communication protocols.

Defining Digital Substation: Key Components

A digital substation integrates advanced communication protocols, merging traditional protection, control, and monitoring equipment into a cohesive digital network. Key components include Intelligent Electronic Devices (IEDs), Process Bus systems, and Ethernet-based communication networks that replace conventional copper wiring. Your electrical infrastructure benefits from improved real-time data accuracy, enhanced reliability, and streamlined maintenance through these digital innovations.

Core Differences: Digital vs Conventional Substations

Digital substations leverage advanced communication protocols and intelligent electronic devices (IEDs) to enhance real-time data monitoring, automation, and fault diagnosis, significantly improving operational efficiency and safety. Conventional substations rely on hardwired connections and analog instrumentation, which can limit data accessibility and increase maintenance complexity. Your choice between digital and conventional substations impacts scalability, integration capabilities, and long-term operational costs, with digital substations offering superior flexibility and intelligent control.

Protection and Control Systems: A Comparative Analysis

Digital substations utilize advanced microprocessor-based protection relays and communication protocols like IEC 61850, enabling faster fault detection and real-time data exchange compared to conventional substations that rely on electromechanical relays and point-to-point wiring. Your protection and control systems benefit from enhanced accuracy, remote diagnostics, and improved reliability in digital substations, reducing downtime and maintenance costs. The integration of smart sensors and intelligent electronic devices (IEDs) in digital substations allows for more adaptive and automated responses to faults, significantly surpassing the capabilities of traditional setups.

Communication Networks in Substations

Digital substations utilize advanced communication networks based on IEC 61850 standards, enabling real-time data exchange and interoperability through fiber-optic cables and Ethernet protocols. Conventional substations rely on hardwired connections and conventional relays, limiting flexibility and data transfer speeds. The shift to digital communication networks enhances monitoring, control, and protection functions, significantly improving substation efficiency and reliability.

Advantages of Digital Substations

Digital substations offer enhanced monitoring and control capabilities through real-time data acquisition and advanced communication protocols, improving operational efficiency and reliability. Your network benefits from reduced physical wiring and space requirements, lowering installation and maintenance costs compared to conventional substations. The integration of intelligent electronic devices (IEDs) enables faster fault detection and automated response, significantly minimizing downtime and enhancing grid stability.

Challenges and Limitations of Both Types

Digital substations face challenges such as high initial costs, cybersecurity vulnerabilities, and reliance on complex software integration, which can complicate maintenance and require specialized skills. Conventional substations are limited by slower fault detection, lack of real-time data processing, and increased physical space requirements due to extensive wiring and equipment. Both types struggle with interoperability issues, where digital systems must integrate with legacy components, posing risks of communication failures and operational inefficiencies.

Implementation and Integration Considerations

Digital substations leverage IEC 61850 communication protocols and IEC standards for seamless integration with advanced protection, control, and monitoring systems, reducing wiring complexity and enabling real-time data exchange. Conventional substations rely on hardwired connections and analog relays, leading to increased installation time, higher maintenance requirements, and limited scalability. Implementing digital substations demands compatibility with intelligent electronic devices (IEDs) and robust cybersecurity measures, while conventional substations prioritize tried-and-true hardware solutions with less emphasis on digital interoperability.

Future Trends in Substation Technology

Digital substations leverage advanced communication protocols like IEC 61850 and real-time data analytics to enhance operational efficiency, predictive maintenance, and fault detection compared to conventional substations relying on analog signaling and manual controls. Future trends include integrating IoT devices, AI-driven automation, and edge computing to enable smarter grid management, improved cyber-security measures, and reduced operational costs. The shift towards fully digital substations supports the development of smart grids and renewable energy integration, meeting increasing demands for reliability and sustainability in power systems.

Digital Substation vs Conventional Substation Infographic

libmatt.com

libmatt.com