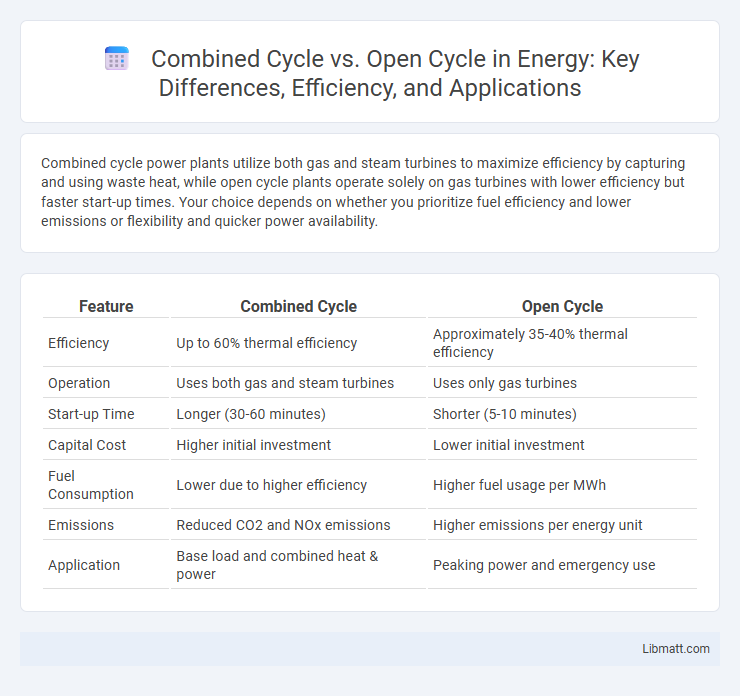

Combined cycle power plants utilize both gas and steam turbines to maximize efficiency by capturing and using waste heat, while open cycle plants operate solely on gas turbines with lower efficiency but faster start-up times. Your choice depends on whether you prioritize fuel efficiency and lower emissions or flexibility and quicker power availability.

Table of Comparison

| Feature | Combined Cycle | Open Cycle |

|---|---|---|

| Efficiency | Up to 60% thermal efficiency | Approximately 35-40% thermal efficiency |

| Operation | Uses both gas and steam turbines | Uses only gas turbines |

| Start-up Time | Longer (30-60 minutes) | Shorter (5-10 minutes) |

| Capital Cost | Higher initial investment | Lower initial investment |

| Fuel Consumption | Lower due to higher efficiency | Higher fuel usage per MWh |

| Emissions | Reduced CO2 and NOx emissions | Higher emissions per energy unit |

| Application | Base load and combined heat & power | Peaking power and emergency use |

Introduction to Power Generation Cycles

Combined cycle power plants utilize both gas and steam turbines to maximize energy efficiency by capturing and reusing waste heat, often achieving thermal efficiencies above 60%. Open cycle plants, typically based on simple gas turbines, convert fuel energy directly to mechanical work, resulting in lower efficiencies around 30-40% but offering faster start-up times and greater operational flexibility. Selection between combined and open cycle power generation depends on balancing efficiency goals, fuel availability, and responsiveness to fluctuating power demands.

What is a Combined Cycle?

A Combined Cycle power plant integrates both gas and steam turbines to enhance efficiency by utilizing waste heat from the gas turbine to generate steam for the steam turbine. This process significantly improves fuel efficiency, often reaching thermal efficiencies above 60%, compared to about 35-40% in Open Cycle systems. Combined Cycle Technology reduces greenhouse gas emissions by making more effective use of fuel energy.

What is an Open Cycle?

An Open Cycle gas turbine operates by drawing air, compressing it, mixing with fuel, and combusting the mixture before directly exhausting hot gases through the turbine to generate power without recovering waste heat. Unlike Combined Cycle systems, open cycle plants do not utilize a heat recovery steam generator (HRSG) to capture exhaust heat for additional electricity production, resulting in lower overall thermal efficiency, typically around 30-40%. Your choice between open cycle and combined cycle depends on factors like startup speed, operational flexibility, and efficiency requirements.

Key Differences Between Combined and Open Cycles

Combined cycle power plants integrate both gas and steam turbines to enhance efficiency, reaching thermal efficiencies of up to 60%, whereas open cycle plants operate solely with gas turbines, typically achieving 30-40% efficiency. Combined cycles recover waste heat from the gas turbine exhaust to generate steam for additional power, significantly reducing fuel consumption and emissions compared to open cycle systems. Open cycle plants offer quicker startup times and lower capital costs, making them suitable for peaking power applications, while combined cycle plants provide superior fuel economy and continuous power generation for base load demands.

Efficiency Comparison: Combined Cycle vs Open Cycle

Combined cycle power plants achieve efficiency rates of up to 60%, significantly higher than the 35-40% efficiency typical of open cycle systems. The combined cycle integrates gas and steam turbines to capture and utilize waste heat, enhancing overall energy conversion. Your choice between these technologies impacts fuel consumption and operational cost due to these efficiency differences.

Environmental Impact Analysis

Combined cycle power plants significantly reduce environmental impact by utilizing waste heat to generate additional electricity, resulting in higher efficiency and lower greenhouse gas emissions compared to open cycle plants. Open cycle plants, typically less efficient, release more CO2 and pollutants due to incomplete fuel combustion and higher fuel consumption per unit of electricity produced. Choosing combined cycle technology can greatly improve your facility's sustainability and compliance with stricter environmental regulations.

Cost Analysis and Economic Considerations

Combined cycle power plants generally offer lower operational costs and higher thermal efficiency compared to open cycle systems, resulting in better fuel utilization and reduced overall expenses. Your investment in a combined cycle setup can provide significant economic advantages due to longer plant life and greater energy output per unit of fuel, despite higher initial capital costs. Open cycle plants incur lower upfront costs but tend to have higher fuel consumption and maintenance expenses, making them less cost-effective for continuous power generation.

Applications and Industry Use Cases

Combined cycle power plants are widely used in large-scale power generation facilities due to their high efficiency and lower emissions, making them ideal for utility companies and industrial complexes aiming to reduce operational costs and environmental impact. Open cycle gas turbines find applications in peak power plants, emergency backup, and oil and gas industries where rapid start-up times and flexibility are critical despite their lower efficiency compared to combined cycle systems. Your choice between these technologies should consider factors such as operational requirements, fuel availability, and project scale to optimize performance and economic benefits.

Advantages and Disadvantages of Each Cycle

Combined Cycle power plants offer higher efficiency by utilizing both gas and steam turbines, resulting in lower fuel consumption and reduced emissions, making them suitable for baseload power generation. Open Cycle systems have simpler design and faster start-up times, which provide flexibility in meeting peak demand but suffer from lower thermal efficiency and higher fuel costs. You should consider Combined Cycle plants for long-term efficiency and environmental benefits, while Open Cycle plants are advantageous for quick deployment and operational flexibility.

Future Trends in Power Generation Technologies

Combined cycle power plants leverage both gas and steam turbines to achieve higher efficiency and lower emissions, making them a leading choice for future power generation technologies. Open cycle plants, though simpler and faster to start, typically have lower efficiency and higher fuel consumption, limiting their long-term viability amid tightening environmental regulations. Your energy strategy will benefit from prioritizing combined cycle systems to meet evolving sustainability goals and optimize operational performance.

Combined Cycle vs Open Cycle Infographic

libmatt.com

libmatt.com