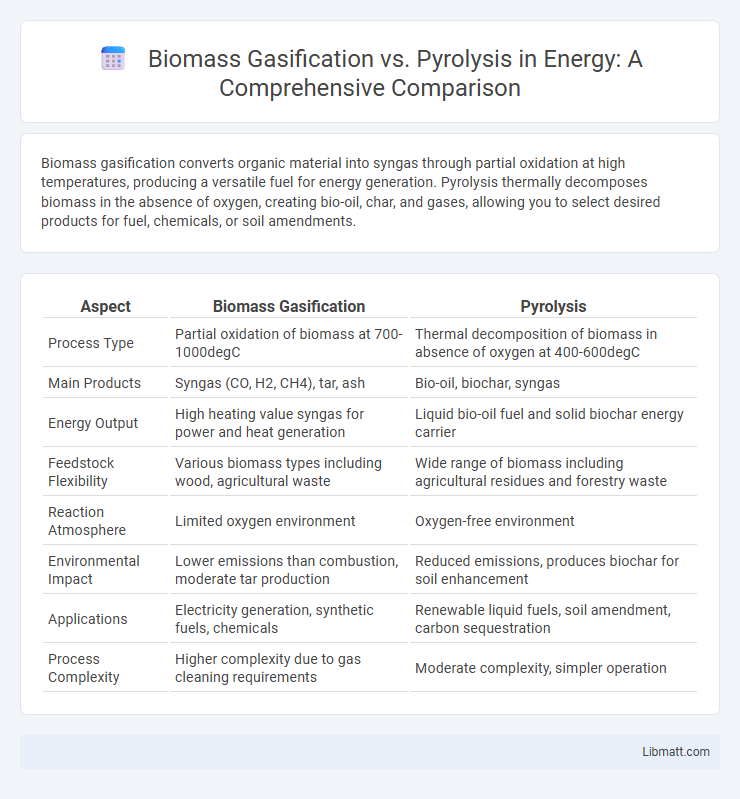

Biomass gasification converts organic material into syngas through partial oxidation at high temperatures, producing a versatile fuel for energy generation. Pyrolysis thermally decomposes biomass in the absence of oxygen, creating bio-oil, char, and gases, allowing you to select desired products for fuel, chemicals, or soil amendments.

Table of Comparison

| Aspect | Biomass Gasification | Pyrolysis |

|---|---|---|

| Process Type | Partial oxidation of biomass at 700-1000degC | Thermal decomposition of biomass in absence of oxygen at 400-600degC |

| Main Products | Syngas (CO, H2, CH4), tar, ash | Bio-oil, biochar, syngas |

| Energy Output | High heating value syngas for power and heat generation | Liquid bio-oil fuel and solid biochar energy carrier |

| Feedstock Flexibility | Various biomass types including wood, agricultural waste | Wide range of biomass including agricultural residues and forestry waste |

| Reaction Atmosphere | Limited oxygen environment | Oxygen-free environment |

| Environmental Impact | Lower emissions than combustion, moderate tar production | Reduced emissions, produces biochar for soil enhancement |

| Applications | Electricity generation, synthetic fuels, chemicals | Renewable liquid fuels, soil amendment, carbon sequestration |

| Process Complexity | Higher complexity due to gas cleaning requirements | Moderate complexity, simpler operation |

Introduction to Biomass Conversion Technologies

Biomass gasification and pyrolysis are key biomass conversion technologies that transform organic materials into valuable fuels and chemicals. Gasification converts biomass into syngas through partial oxidation at high temperatures, enabling efficient energy generation and chemical synthesis. Pyrolysis thermally decomposes biomass in an oxygen-free environment, producing bio-oil, char, and syngas, offering versatile applications for sustainable energy and material production.

What is Biomass Gasification?

Biomass gasification is a thermal conversion process that transforms organic materials into syngas, a mixture of carbon monoxide, hydrogen, and methane, through partial oxidation at high temperatures. This method efficiently converts biomass into a clean, renewable energy source suitable for power generation, heating, or as a precursor for biofuels. Your choice of gasification technology can significantly impact the efficiency and environmental benefits of biomass energy production.

What is Biomass Pyrolysis?

Biomass pyrolysis is a thermochemical decomposition process that converts organic materials into bio-oil, syngas, and biochar by heating biomass in the absence of oxygen. This method produces valuable renewable energy products and soil-enhancing biochar while operating at lower temperatures compared to gasification. Your choice between pyrolysis and gasification depends on desired outputs, with pyrolysis favoring liquid and solid biofuels for energy and agricultural uses.

Key Differences Between Gasification and Pyrolysis

Biomass gasification involves partial oxidation of organic material at high temperatures to produce syngas, a mixture of hydrogen, carbon monoxide, and methane, whereas pyrolysis decomposes biomass thermally in the absence of oxygen, resulting in bio-oil, syngas, and char. Gasification operates typically at temperatures above 700degC with limited oxygen supply, maximizing gaseous fuel yield, while pyrolysis occurs between 300degC and 600degC with no oxygen, favoring liquid bio-oil production. The key difference lies in the oxygen presence and reaction conditions, influencing the type and proportions of energy products generated from biomass.

Feedstock Requirements for Gasification vs Pyrolysis

Biomass gasification requires feedstocks with low moisture content, typically less than 20%, to ensure efficient conversion into syngas, while pyrolysis can process a wider range of feedstocks, including those with higher moisture levels up to 30-40%. Gasification feedstocks favor uniform particle size to maintain consistent temperature and reaction rates, whereas pyrolysis is more flexible regarding particle size and feedstock heterogeneity. These differing feedstock requirements influence the design and operational conditions of gasification and pyrolysis systems in bioenergy production.

End Products: Syngas vs Bio-Oil

Biomass gasification primarily produces syngas, a clean, combustible mixture of carbon monoxide, hydrogen, and methane, ideal for electricity generation and chemical synthesis. In contrast, pyrolysis yields bio-oil, a liquid fuel rich in energy content, suitable for transportation fuels and chemical feedstocks. Understanding the differences in your desired end product helps optimize the choice between gasification and pyrolysis for efficient biomass conversion.

Energy Efficiency Comparison

Biomass gasification generally achieves higher energy efficiency, converting 60-75% of feedstock energy into useful syngas, while pyrolysis efficiency ranges from 50-65%, producing bio-oil, gas, and char. Gasification operates at higher temperatures (800-1,200degC), enhancing conversion rates and reducing tar formation compared to pyrolysis, which occurs at lower temperatures (400-700degC) and yields more liquid products suitable for fuel refining. Your choice between these technologies depends on the desired energy output form and overall system efficiency requirements.

Environmental Impact Assessment

Biomass gasification produces syngas with lower tar and particulate emissions compared to pyrolysis, resulting in reduced air pollution and greenhouse gas emissions. Pyrolysis generates bio-oil and charcoal but often releases more volatile organic compounds, impacting local air quality. Both technologies contribute to carbon neutrality by utilizing renewable biomass, but gasification offers improved environmental efficiency through cleaner energy output and minimized waste byproducts.

Commercial Applications and Market Potential

Biomass gasification is widely utilized in power generation and industrial fuel production due to its efficiency in converting diverse feedstocks into syngas, fueling combined heat and power (CHP) systems and hydrogen production with strong market demand across Asia and Europe. Pyrolysis excels in producing bio-oil, biochar, and syngas, catering to biofuel markets and agricultural applications, with growing interest in carbon sequestration and soil enhancement boosting its commercial appeal. Market potential analysis indicates gasification's dominance in large-scale energy projects, while pyrolysis gains traction in niche sectors focused on sustainability and circular bioeconomy solutions.

Future Trends in Biomass Gasification and Pyrolysis

Future trends in biomass gasification emphasize the integration of advanced catalysts and high-efficiency gas cleaning technologies to enhance syngas quality for power generation and chemical synthesis. Innovations in fast pyrolysis focus on improving bio-oil yield and stability, supporting scalable production of renewable fuels and specialty chemicals. Both processes are increasingly aligned with circular economy principles, leveraging waste feedstocks and improving carbon capture and utilization to reduce greenhouse gas emissions.

Biomass Gasification vs Pyrolysis Infographic

libmatt.com

libmatt.com