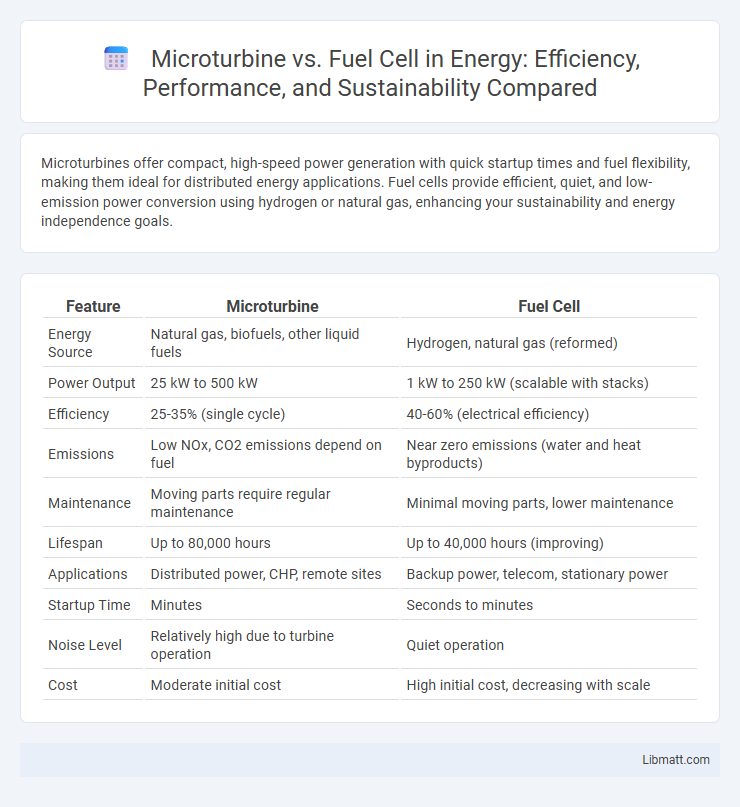

Microturbines offer compact, high-speed power generation with quick startup times and fuel flexibility, making them ideal for distributed energy applications. Fuel cells provide efficient, quiet, and low-emission power conversion using hydrogen or natural gas, enhancing your sustainability and energy independence goals.

Table of Comparison

| Feature | Microturbine | Fuel Cell |

|---|---|---|

| Energy Source | Natural gas, biofuels, other liquid fuels | Hydrogen, natural gas (reformed) |

| Power Output | 25 kW to 500 kW | 1 kW to 250 kW (scalable with stacks) |

| Efficiency | 25-35% (single cycle) | 40-60% (electrical efficiency) |

| Emissions | Low NOx, CO2 emissions depend on fuel | Near zero emissions (water and heat byproducts) |

| Maintenance | Moving parts require regular maintenance | Minimal moving parts, lower maintenance |

| Lifespan | Up to 80,000 hours | Up to 40,000 hours (improving) |

| Applications | Distributed power, CHP, remote sites | Backup power, telecom, stationary power |

| Startup Time | Minutes | Seconds to minutes |

| Noise Level | Relatively high due to turbine operation | Quiet operation |

| Cost | Moderate initial cost | High initial cost, decreasing with scale |

Introduction: Microturbines vs Fuel Cells Overview

Microturbines generate electricity through high-speed combustion of fuel, offering compact size and rapid startup capabilities, suitable for distributed power generation. Fuel cells convert chemical energy from fuels like hydrogen directly into electricity via electrochemical reactions, providing high efficiency and low emissions. Both technologies serve as clean energy solutions but differ in operational mechanisms, fuel flexibility, and application scope.

How Microturbines Work

Microturbines generate electricity by burning fuel to produce high-temperature, high-pressure gases that spin a turbine connected to an electric generator. Their compact design allows for efficient energy conversion with lower emissions compared to traditional combustion engines. Your choice between microturbines and fuel cells depends on factors like fuel type, efficiency, and operational scale for your energy needs.

How Fuel Cells Operate

Fuel cells generate electricity through an electrochemical reaction between hydrogen and oxygen, producing water and heat as byproducts, which results in highly efficient, clean energy conversion. Unlike microturbines that rely on combustion to drive mechanical rotation, fuel cells operate silently without moving parts, reducing maintenance requirements and improving reliability. Your choice of energy system can benefit from fuel cells' ability to provide consistent power with lower emissions, making them ideal for sustainable and resilient applications.

Efficiency Comparison: Microturbines vs Fuel Cells

Fuel cells typically achieve higher electrical efficiencies ranging from 40% to 60%, with combined heat and power (CHP) applications pushing overall efficiency beyond 80%, whereas microturbines generally operate at electrical efficiencies between 25% and 35%, with CHP efficiency reaching up to 85%. Fuel cells' electrochemical conversion process reduces energy losses compared to microturbines' combustion-based operation, which results in lower CO2 emissions per unit of electricity produced. In distributed generation and clean energy applications, fuel cells often provide superior fuel-to-electricity conversion efficiency, making them preferable for maximizing energy utilization and minimizing environmental impact.

Environmental Impact and Emissions

Microturbines typically emit higher levels of nitrogen oxides (NOx) and carbon dioxide (CO2) due to combustion processes, contributing to air pollution and greenhouse gas emissions. Fuel cells operate with near-zero emissions, producing only water and heat as byproducts, significantly reducing environmental impact. Their higher efficiency and clean energy conversion make fuel cells a more sustainable option for reducing carbon footprints and meeting stringent emission regulations.

Applications in Power Generation

Microturbines excel in distributed power generation and combined heat and power (CHP) systems, offering high reliability for commercial and industrial applications with capacities typically ranging from 30 kW to 500 kW. Fuel cells provide clean, efficient power generation with lower emissions, making them ideal for stationary power in remote locations, backup power, and emerging hydrogen economy applications, often delivering modular power outputs from a few kilowatts up to several megawatts. Both technologies support grid resilience but fuel cells lead in sustainability and microturbines in fuel flexibility and rapid start-up for diverse power generation needs.

Installation and Maintenance Requirements

Microturbines require compact installation with minimal infrastructure, benefiting from fewer moving parts that reduce routine maintenance needs but still demand regular inspections for air filters and bearings. Fuel cells involve more complex installation due to sensitive components and precise fuel supply systems, necessitating specialized maintenance to manage stack integrity and water management for optimal performance. Your choice depends on balancing the relatively straightforward upkeep of microturbines against the technical maintenance expertise required for fuel cells.

Cost Analysis: Initial Investment and Operating Expenses

Microturbines typically require a lower initial investment compared to fuel cells, with costs ranging from $1,200 to $1,700 per kW versus $3,000 to $4,500 per kW for fuel cells. Operating expenses for microturbines are generally higher due to maintenance and fuel costs, averaging around 3-7 cents per kWh, while fuel cells benefit from lower maintenance but can face higher fuel expenses depending on the type. Your decision should weigh upfront capital against long-term operational savings to find the most cost-effective solution for your energy needs.

Future Trends and Technology Developments

Microturbines are evolving with improvements in fuel flexibility and integration with renewable energy sources, enhancing their efficiency and reducing emissions. Fuel cells are advancing rapidly through innovations in solid oxide and proton exchange membrane technologies, driving higher electrical efficiency and lower operating temperatures. Your choice should consider the increasing adoption of hybrid systems combining microturbines and fuel cells to optimize performance and sustainability in future energy solutions.

Choosing the Right Solution: Key Considerations

Selecting between microturbines and fuel cells depends on factors such as efficiency, fuel flexibility, and environmental impact. Microturbines offer higher power output and fast start-up times, making them suitable for large-scale or grid-support applications, while fuel cells provide higher electrical efficiency with lower emissions, ideal for stationary power in sensitive environments. Evaluating operational costs, maintenance requirements, and site-specific energy demands ensures the optimal energy solution tailored to economic and sustainability goals.

Microturbine vs Fuel cell Infographic

libmatt.com

libmatt.com