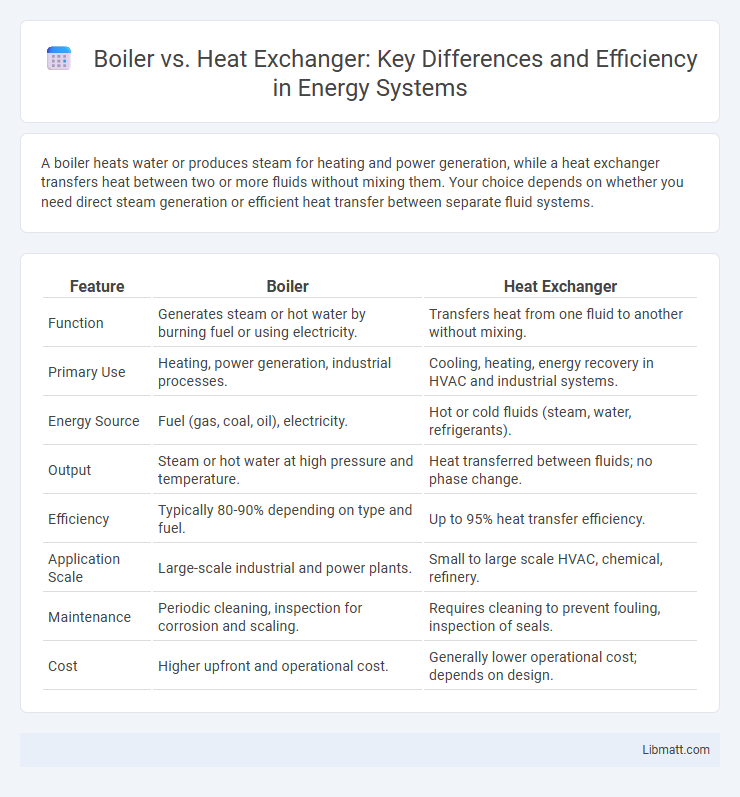

A boiler heats water or produces steam for heating and power generation, while a heat exchanger transfers heat between two or more fluids without mixing them. Your choice depends on whether you need direct steam generation or efficient heat transfer between separate fluid systems.

Table of Comparison

| Feature | Boiler | Heat Exchanger |

|---|---|---|

| Function | Generates steam or hot water by burning fuel or using electricity. | Transfers heat from one fluid to another without mixing. |

| Primary Use | Heating, power generation, industrial processes. | Cooling, heating, energy recovery in HVAC and industrial systems. |

| Energy Source | Fuel (gas, coal, oil), electricity. | Hot or cold fluids (steam, water, refrigerants). |

| Output | Steam or hot water at high pressure and temperature. | Heat transferred between fluids; no phase change. |

| Efficiency | Typically 80-90% depending on type and fuel. | Up to 95% heat transfer efficiency. |

| Application Scale | Large-scale industrial and power plants. | Small to large scale HVAC, chemical, refinery. |

| Maintenance | Periodic cleaning, inspection for corrosion and scaling. | Requires cleaning to prevent fouling, inspection of seals. |

| Cost | Higher upfront and operational cost. | Generally lower operational cost; depends on design. |

Introduction to Boilers and Heat Exchangers

Boilers generate steam or hot water by heating fluid through combustion or electric energy, widely used in heating, power generation, and industrial processes. Heat exchangers transfer heat between two or more fluids without mixing them, essential for energy conservation and efficient thermal management in HVAC, chemical processing, and refrigeration. Understanding these systems can help you optimize energy use and enhance process efficiency in your applications.

How Boilers Work: Key Principles

Boilers operate by burning fuel or utilizing electricity to heat water, producing steam or hot water used for heating and power generation. The key principle involves transferring heat from combustion gases or electric elements through a heat exchanger surface to the water. Efficient design maximizes heat transfer while minimizing heat loss, ensuring optimal energy conversion in the boiler system.

How Heat Exchangers Operate

Heat exchangers operate by transferring thermal energy between two or more fluids without mixing them, using conductive and convective heat transfer principles through a metal barrier. Your system benefits from enhanced efficiency as heat exchangers maintain distinct fluid pathways, enabling precise temperature control in industrial, HVAC, and refrigeration applications. This separation reduces contamination risks and energy waste compared to traditional boilers that directly heat fluids through combustion.

Key Differences Between Boilers and Heat Exchangers

Boilers generate steam or hot water by heating fluids through combustion, serving as a primary source of thermal energy, while heat exchangers transfer heat between two or more fluids without direct contact, optimizing energy efficiency in systems. Boilers operate at high pressures and temperatures to produce steam for power generation or heating, whereas heat exchangers function at lower pressure differences to facilitate heat transfer in HVAC, chemical, and industrial processes. Key differences include purpose--boilers produce heat, and heat exchangers transfer heat--along with structural design, fluid flow configurations, and operational conditions tailored to specific applications.

Applications: Boiler vs Heat Exchanger

Boilers are primarily used in power generation, industrial steam production, and heating systems to convert water into steam for mechanical work or heating purposes. Heat exchangers serve a broader range of applications including HVAC systems, chemical processing, refrigeration, and waste heat recovery by transferring heat between fluids without mixing them. While boilers generate steam for energy output, heat exchangers facilitate thermal energy transfer to improve energy efficiency across industries.

Energy Efficiency Comparison

Boilers and heat exchangers differ significantly in energy efficiency, with heat exchangers typically offering superior energy transfer performance due to their enhanced surface area design and optimized heat recovery capabilities. Boilers often consume more fuel energy to generate steam or hot water, resulting in higher operational costs and increased energy waste compared to heat exchangers that leverage existing thermal energy sources effectively. Your choice between the two should consider the specific application's demand for efficient energy use, where heat exchangers can substantially reduce fuel consumption and improve sustainability.

Maintenance Requirements and Costs

Boilers require regular inspection, cleaning of fuel lines, and monitoring of pressure gauges to prevent scaling and corrosion, resulting in moderate to high maintenance costs depending on fuel type and usage frequency. Heat exchangers demand frequent cleaning to remove fouling and routine checks for leaks or cracks, which generally incur lower maintenance expenses but can vary based on the exchanger material and process conditions. Both systems benefit from predictive maintenance technologies to extend service life and optimize operational efficiency, impacting overall maintenance budgets.

Installation Considerations

Boiler installation requires sufficient space, proper ventilation, and adherence to safety regulations to handle high-pressure steam or hot water generation. Heat exchanger installation demands precise alignment and compatibility with existing systems to ensure efficient thermal transfer without leaks. Your choice impacts the complexity and cost of installation, so evaluation of system requirements and maintenance access is crucial.

Safety Features and Concerns

Boilers incorporate multiple safety features like pressure relief valves, low-water cutoffs, and flame failure detectors to prevent explosions and overheating, ensuring safe operation in high-pressure environments. Heat exchangers, while generally operating under lower pressure, focus on preventing leaks and thermal stress through robust materials and proper maintenance to avoid cross-contamination and equipment failure. Understanding these safety aspects helps you choose the right system that aligns with your operational risk tolerance and maintenance capabilities.

Choosing the Right System for Your Needs

Choosing the right system between a boiler and a heat exchanger depends on your specific heating requirements and efficiency goals. Boilers generate steam or hot water directly for heating, making them ideal for residential or industrial applications needing consistent, high-temperature output. Heat exchangers transfer heat between fluids without mixing them, offering energy-efficient solutions in processes like HVAC systems or chemical plants where maintaining fluid separation is essential for safety and performance.

Boiler vs Heat Exchanger Infographic

libmatt.com

libmatt.com