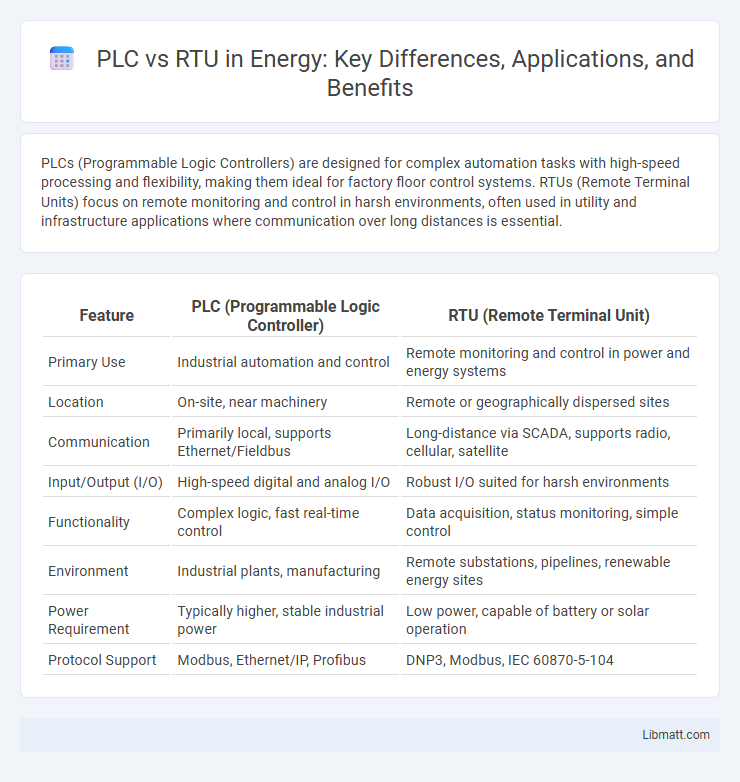

PLCs (Programmable Logic Controllers) are designed for complex automation tasks with high-speed processing and flexibility, making them ideal for factory floor control systems. RTUs (Remote Terminal Units) focus on remote monitoring and control in harsh environments, often used in utility and infrastructure applications where communication over long distances is essential.

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | RTU (Remote Terminal Unit) |

|---|---|---|

| Primary Use | Industrial automation and control | Remote monitoring and control in power and energy systems |

| Location | On-site, near machinery | Remote or geographically dispersed sites |

| Communication | Primarily local, supports Ethernet/Fieldbus | Long-distance via SCADA, supports radio, cellular, satellite |

| Input/Output (I/O) | High-speed digital and analog I/O | Robust I/O suited for harsh environments |

| Functionality | Complex logic, fast real-time control | Data acquisition, status monitoring, simple control |

| Environment | Industrial plants, manufacturing | Remote substations, pipelines, renewable energy sites |

| Power Requirement | Typically higher, stable industrial power | Low power, capable of battery or solar operation |

| Protocol Support | Modbus, Ethernet/IP, Profibus | DNP3, Modbus, IEC 60870-5-104 |

Introduction to PLC and RTU

Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs) are essential components in industrial automation and control systems. PLCs are designed for centralized control with high-speed processing and robust programmability, ideal for factory automation and complex logic operations. RTUs specialize in remote monitoring and data acquisition with rugged construction suitable for harsh environments, enabling efficient control of geographically dispersed assets to support your industrial system needs.

Key Differences Between PLC and RTU

Programmable Logic Controllers (PLCs) primarily serve industrial automation with fast processing speeds and complex control logic, while Remote Terminal Units (RTUs) specialize in remote monitoring and control in wide-area environments like utilities. PLCs offer modular design and extensive I/O options for factory automation, whereas RTUs provide robust communication capabilities across SCADA systems with long-distance telemetry. Key differences include PLCs' emphasis on real-time control within confined spaces versus RTUs' focus on reliable data acquisition and transmission in harsh, dispersed locations.

Core Functions of PLC Systems

PLC systems primarily control industrial processes through real-time monitoring, automation, and data acquisition. Their core functions include executing programmed logic operations, managing inputs and outputs from sensors and actuators, and ensuring system reliability in harsh environments. You can optimize production efficiency and minimize downtime by leveraging PLC's precise control and flexible programming capabilities.

Core Functions of RTU Systems

RTU systems primarily excel in remote monitoring and control of distributed assets, enabling real-time data acquisition from sensors and field devices in harsh or inaccessible environments. They specialize in telemetry, offering reliable communication over long distances using protocols like DNP3 and Modbus, ensuring seamless integration with SCADA systems for centralized management. Your operational efficiency benefits from RTUs' robust design for continuous data logging, event alarming, and local decision-making capabilities crucial for utility, oil and gas, and water treatment industries.

PLC vs RTU: Hardware Architecture

PLC hardware architecture typically consists of a compact modular design with a central processing unit (CPU), input/output (I/O) modules, power supply, and communication interfaces, optimized for industrial automation tasks. RTU hardware architecture is designed for remote and distributed control, featuring ruggedized components, lower power consumption, diverse communication options (such as radio or satellite), and integration with SCADA systems. PLCs excel in processing complex control algorithms locally, while RTUs prioritize durability and reliable data acquisition in harsh or remote environments.

Communication Capabilities: PLC vs RTU

Programmable Logic Controllers (PLCs) typically offer advanced communication capabilities with support for multiple industrial protocols such as Modbus TCP/IP, Ethernet/IP, and Profibus, enabling seamless integration into modern automation networks. Remote Terminal Units (RTUs) prioritize long-range communication and reliability, often utilizing protocols like DNP3 and IEC 60870-5-104 to ensure robust data transmission over wide-area networks. The selection between PLC and RTU communication depends largely on application requirements, with PLCs excelling in high-speed, localized control systems and RTUs optimized for remote monitoring and SCADA system interfacing.

Application Areas: Where Each Device Excels

PLCs excel in industrial automation environments such as manufacturing lines, robotics, and process control where real-time processing and complex logic operations are crucial. RTUs are designed for remote monitoring and control in distributed systems like oil and gas pipelines, water treatment plants, and electrical substations where robust communication and environmental durability are essential. Each device excels according to system requirements, with PLCs dominating localized, high-speed control and RTUs optimized for remote, wide-area telemetry and SCADA integration.

Scalability and Flexibility Comparison

PLCs offer high scalability through modular hardware configurations allowing easy expansion of I/O points and integration of new functionalities to adapt to evolving industrial processes. RTUs excel in flexibility with robust communication protocols designed for remote monitoring and control across geographically dispersed locations, making them ideal for large-scale distributed systems. Your choice depends on whether scalability in localized automation or flexibility in remote data acquisition is the priority.

Cost Considerations: PLC vs RTU

PLC systems generally incur higher initial costs due to advanced processing capabilities and extensive modular options, while RTUs offer cost-effective solutions tailored for remote monitoring with lower maintenance expenses. PLCs demand investment in software licensing and specialized programming, increasing overall costs in complex automation projects. RTUs provide economical scalability in distributed environments, making them ideal for extensive field deployments with budget constraints.

Choosing the Right Solution for Your Needs

Selecting between a Programmable Logic Controller (PLC) and a Remote Terminal Unit (RTU) depends on the specific operational requirements and environment of the application. PLCs excel in industrial automation where rapid processing and complex control logic are necessary, while RTUs are ideal for remote monitoring and control with robust communication capabilities in harsh or distributed environments. Evaluating factors such as system scalability, communication protocols, and environmental conditions ensures the best fit for operational efficiency and reliability.

PLC vs RTU Infographic

libmatt.com

libmatt.com