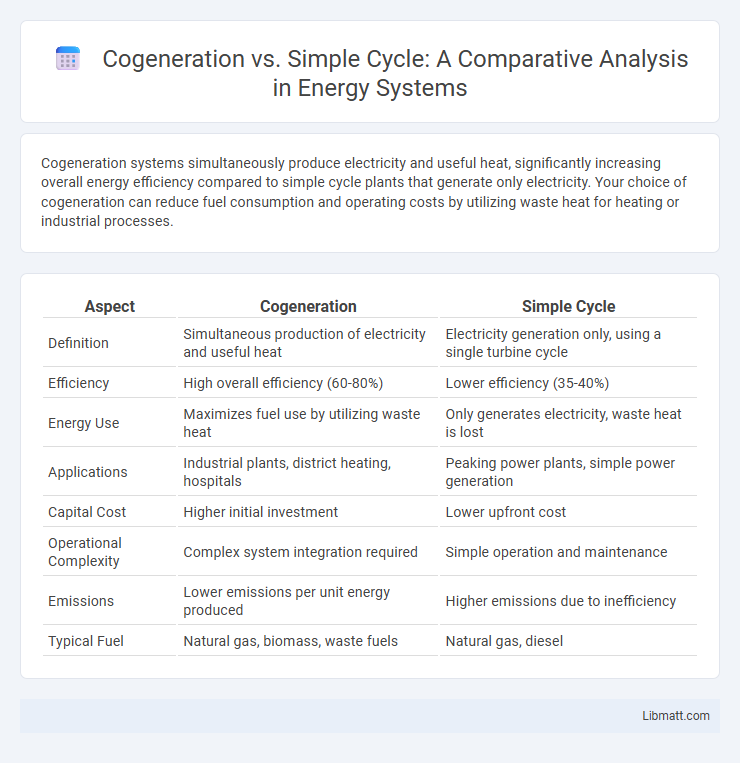

Cogeneration systems simultaneously produce electricity and useful heat, significantly increasing overall energy efficiency compared to simple cycle plants that generate only electricity. Your choice of cogeneration can reduce fuel consumption and operating costs by utilizing waste heat for heating or industrial processes.

Table of Comparison

| Aspect | Cogeneration | Simple Cycle |

|---|---|---|

| Definition | Simultaneous production of electricity and useful heat | Electricity generation only, using a single turbine cycle |

| Efficiency | High overall efficiency (60-80%) | Lower efficiency (35-40%) |

| Energy Use | Maximizes fuel use by utilizing waste heat | Only generates electricity, waste heat is lost |

| Applications | Industrial plants, district heating, hospitals | Peaking power plants, simple power generation |

| Capital Cost | Higher initial investment | Lower upfront cost |

| Operational Complexity | Complex system integration required | Simple operation and maintenance |

| Emissions | Lower emissions per unit energy produced | Higher emissions due to inefficiency |

| Typical Fuel | Natural gas, biomass, waste fuels | Natural gas, diesel |

Introduction to Cogeneration and Simple Cycle

Cogeneration, also known as combined heat and power (CHP), simultaneously produces electricity and useful thermal energy from a single fuel source, significantly enhancing overall energy efficiency by capturing heat that would otherwise be wasted. Simple cycle power plants generate electricity by burning fuel in a gas turbine or engine, with exhaust heat released into the atmosphere without recovery, resulting in lower efficiency compared to cogeneration systems. The key difference lies in cogeneration's ability to utilize waste heat for industrial processes, heating, or cooling, making it ideal for facilities with continuous thermal energy demands.

Definition of Cogeneration Systems

Cogeneration systems, also known as combined heat and power (CHP) systems, simultaneously produce electricity and useful thermal energy from a single fuel source, maximizing overall efficiency compared to simple cycle power plants that only generate electricity. By recovering waste heat for heating or industrial processes, cogeneration reduces fuel consumption and lowers emissions. Your energy costs and environmental impact can significantly improve with the integration of cogeneration systems over conventional simple cycle systems.

Simple Cycle Power Generation Explained

Simple cycle power generation involves a gas turbine that converts fuel directly into mechanical energy to drive a generator, producing electricity without recovering exhaust heat. This process results in lower overall efficiency, typically around 33-40%, compared to cogeneration systems that capture waste heat for additional energy use. Simple cycle plants are favored for rapid startup and peak power demands but are less efficient and environmentally friendly than combined heat and power (CHP) configurations.

Key Technology Differences

Cogeneration systems simultaneously produce electricity and useful heat by capturing waste heat from the power generation process, significantly increasing overall energy efficiency. Simple cycle plants generate electricity alone by combusting fuel in a gas turbine, with exhaust heat released unused, resulting in lower thermal efficiency. Your choice between these technologies impacts energy utilization, operating costs, and environmental footprint based on whether you prioritize combined heat and power or straightforward electricity generation.

Efficiency Comparison: Cogeneration vs Simple Cycle

Cogeneration systems achieve electrical efficiencies of 60-80% by simultaneously producing electricity and useful heat, significantly outperforming simple cycle gas turbines, which typically reach 35-40% electrical efficiency. Simple cycle units lose much energy as waste heat, whereas cogeneration captures this thermal energy for heating or industrial processes, enhancing overall fuel utilization. This increased efficiency translates to lower fuel costs and reduced carbon emissions in cogeneration compared to simple cycle power generation.

Environmental Impact and Emissions

Cogeneration systems achieve higher energy efficiency by simultaneously producing electricity and useful heat, significantly reducing greenhouse gas emissions compared to simple cycle power plants. Simple cycle plants typically burn fuel solely for electricity production, resulting in greater carbon dioxide and nitrogen oxide emissions per unit of energy delivered. Implementing cogeneration can lower overall environmental impact by up to 30-40% through reduced fuel consumption and minimized pollutant output.

Energy Cost Analysis

Cogeneration systems significantly reduce energy costs by simultaneously producing electricity and useful heat, achieving overall efficiency of 70-90%, compared to simple cycle plants with efficiencies around 33-40%. Your operational savings are amplified as cogeneration recycles waste heat for industrial or heating purposes, cutting fuel consumption and lowering utility expenses. Despite higher initial investment, cogeneration's lower levelized cost of energy (LCOE) often delivers superior long-term economic benefits over simple cycle configurations.

Application Areas and Use Cases

Cogeneration systems excel in industrial plants, hospitals, and large commercial buildings by simultaneously producing electricity and useful heat, significantly improving energy efficiency and reducing operational costs. Simple cycle gas turbines are commonly used for peak load power generation, remote locations, and quick-start applications due to their lower upfront costs and rapid startup times. While cogeneration is ideal for facilities with continuous thermal and electrical demands, simple cycle units suit intermittent power needs and emergency backup scenarios.

Future Trends and Innovations

Future trends in cogeneration emphasize enhanced energy efficiency and integration with renewable sources, positioning it as a key player in sustainable power generation. Innovations include advanced heat recovery systems and smart grid compatibility, improving operational flexibility compared to simple cycle plants. Your energy strategy benefits from cogeneration's evolving technology, offering reduced emissions and lower operational costs.

Choosing the Best System for Your Needs

Evaluating cogeneration versus simple cycle systems hinges on your energy efficiency goals and operational demands. Cogeneration maximizes fuel use by producing electricity and useful heat simultaneously, ideal for facilities requiring both power and thermal energy, resulting in up to 80% efficiency. Simple cycle systems offer faster start-up and lower capital costs, making them suitable for peak power needs or locations where heat recovery isn't necessary.

Cogeneration vs Simple cycle Infographic

libmatt.com

libmatt.com