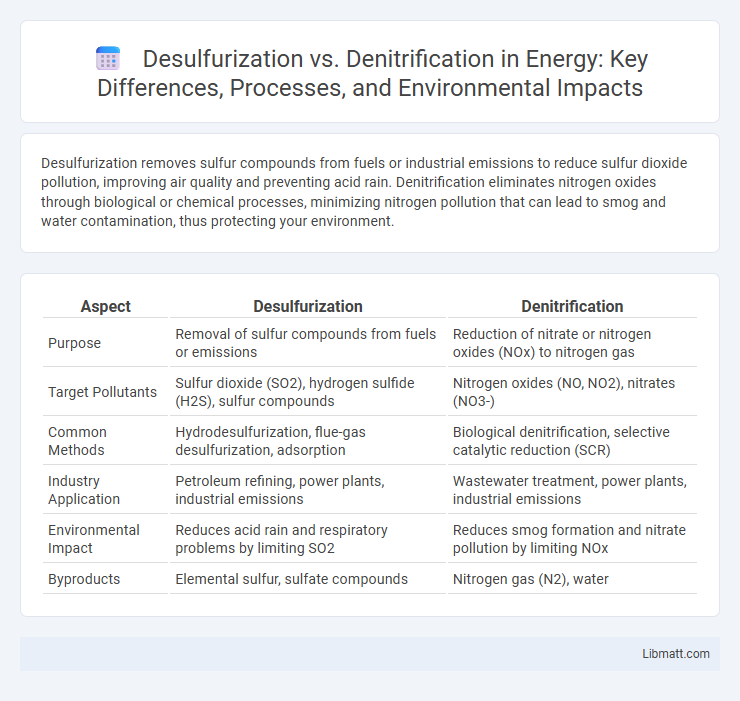

Desulfurization removes sulfur compounds from fuels or industrial emissions to reduce sulfur dioxide pollution, improving air quality and preventing acid rain. Denitrification eliminates nitrogen oxides through biological or chemical processes, minimizing nitrogen pollution that can lead to smog and water contamination, thus protecting your environment.

Table of Comparison

| Aspect | Desulfurization | Denitrification |

|---|---|---|

| Purpose | Removal of sulfur compounds from fuels or emissions | Reduction of nitrate or nitrogen oxides (NOx) to nitrogen gas |

| Target Pollutants | Sulfur dioxide (SO2), hydrogen sulfide (H2S), sulfur compounds | Nitrogen oxides (NO, NO2), nitrates (NO3-) |

| Common Methods | Hydrodesulfurization, flue-gas desulfurization, adsorption | Biological denitrification, selective catalytic reduction (SCR) |

| Industry Application | Petroleum refining, power plants, industrial emissions | Wastewater treatment, power plants, industrial emissions |

| Environmental Impact | Reduces acid rain and respiratory problems by limiting SO2 | Reduces smog formation and nitrate pollution by limiting NOx |

| Byproducts | Elemental sulfur, sulfate compounds | Nitrogen gas (N2), water |

Introduction to Desulfurization and Denitrification

Desulfurization removes sulfur compounds from fuels or industrial emissions to reduce sulfur dioxide pollution and acid rain formation. Denitrification is a microbial process that converts nitrate into nitrogen gas, reducing nitrogen oxide emissions responsible for smog and respiratory issues. Understanding these processes helps you select effective environmental strategies for controlling air pollutants.

Importance of Removing Sulfur and Nitrogen Compounds

Removing sulfur and nitrogen compounds is crucial for reducing air pollution and preventing acid rain, which adversely affect ecosystems and human health. Sulfur compounds, primarily sulfur dioxide (SO2), contribute to respiratory problems and environmental damage, while nitrogen compounds, especially nitrogen oxides (NOx), lead to smog formation and ozone layer depletion. Efficient desulfurization and denitrification processes in industrial emissions help comply with environmental regulations, improve air quality, and protect biodiversity.

Fundamental Principles of Desulfurization

Desulfurization involves the removal of sulfur compounds from fuels or industrial emissions to reduce sulfur oxide pollutants, primarily using chemical or biological methods such as adsorptive desulfurization, hydrodesulfurization, or biodesulfurization. The fundamental principles focus on breaking the sulfur-carbon bonds in organic sulfur compounds or converting sulfur compounds into less harmful substances like hydrogen sulfide or sulfate ions. Your choice of desulfurization technique depends on factors like sulfur concentration, type of feedstock, and environmental regulations.

Fundamental Principles of Denitrification

Denitrification is a microbial process that converts nitrate (NO3-) into nitrogen gas (N2), effectively removing nitrogen from wastewater under anaerobic conditions. It involves a series of enzymatic reductions where nitrate is sequentially reduced to nitrite, nitric oxide, nitrous oxide, and finally nitrogen gas. This process is essential for controlling nitrogen pollution, reducing eutrophication risks, and maintaining ecosystem balance in aquatic environments.

Comparison of Chemical Processes

Desulfurization primarily involves the chemical removal of sulfur compounds from fuels or industrial gases, often using processes like flue gas desulfurization (FGD) with limestone or lime scrubbers to convert sulfur dioxide (SO2) into gypsum. Denitrification targets the reduction of nitrogen oxides (NOx) emissions through selective catalytic reduction (SCR) or selective non-catalytic reduction (SNCR) methods, converting NOx into nitrogen (N2) and water (H2O) under controlled temperature conditions. Both processes utilize distinct chemical reactions to mitigate specific pollutants, with desulfurization focusing on acid gas neutralization and denitrification emphasizing redox reactions for nitrogen oxide removal.

Industrial Applications of Desulfurization

Desulfurization is a critical industrial process used extensively to remove sulfur compounds from fuels and gases, thereby reducing harmful sulfur dioxide emissions and meeting environmental regulations. This process is vital in refining petroleum, processing natural gas, and treating industrial flue gases to prevent acid rain and equipment corrosion. Your compliance with stricter emission standards relies heavily on efficient desulfurization technologies like hydrodesulfurization and fluidized bed desulfurization.

Industrial Applications of Denitrification

Denitrification plays a vital role in industrial wastewater treatment by removing excess nitrates and preventing eutrophication in natural water bodies. It is extensively applied in chemical manufacturing, power plants, and fertilizer industries to reduce nitrogen oxide emissions and comply with environmental regulations. Industrial denitrification enhances water quality by converting harmful nitrates into harmless nitrogen gas through microbial processes.

Environmental Impact and Benefits

Desulfurization significantly reduces sulfur dioxide (SO2) emissions, lowering acid rain and respiratory health risks, while denitrification targets nitrogen oxides (NOx), preventing smog and ground-level ozone formation. Both processes enhance air quality by mitigating harmful pollutants from industrial and vehicular sources, contributing to ecosystem protection and public health improvement. Implementing advanced desulfurization and denitrification technologies promotes compliance with environmental regulations and supports sustainable development goals by reducing greenhouse gas precursors and toxic emissions.

Technological Innovations in Sulfur and Nitrogen Removal

Technological innovations in desulfurization leverage advanced methods like flue gas desulfurization (FGD) with wet scrubbers and regenerative processes to efficiently remove sulfur oxides (SOx) from industrial emissions. In denitrification, selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR) technologies have evolved to convert nitrogen oxides (NOx) into harmless nitrogen and water vapor, enhancing nitrogen removal efficiency. Emerging hybrid systems combining biofiltration with chemical absorption further optimize simultaneous sulfur and nitrogen removal in air pollution control systems.

Future Trends in Emission Control Technologies

Future trends in emission control technologies emphasize advanced desulfurization methods like regenerative catalyst systems and membrane-based sulfur removal for higher efficiency and lower operational costs. Emerging denitrification technologies prioritize selective catalytic reduction (SCR) enhancements and bio-denitrification innovations to achieve near-zero nitrogen oxide (NOx) emissions. Your decisions on emission control investments should consider these cutting-edge solutions to comply with stricter environmental regulations and promote sustainable industrial practices.

Desulfurization vs Denitrification Infographic

libmatt.com

libmatt.com