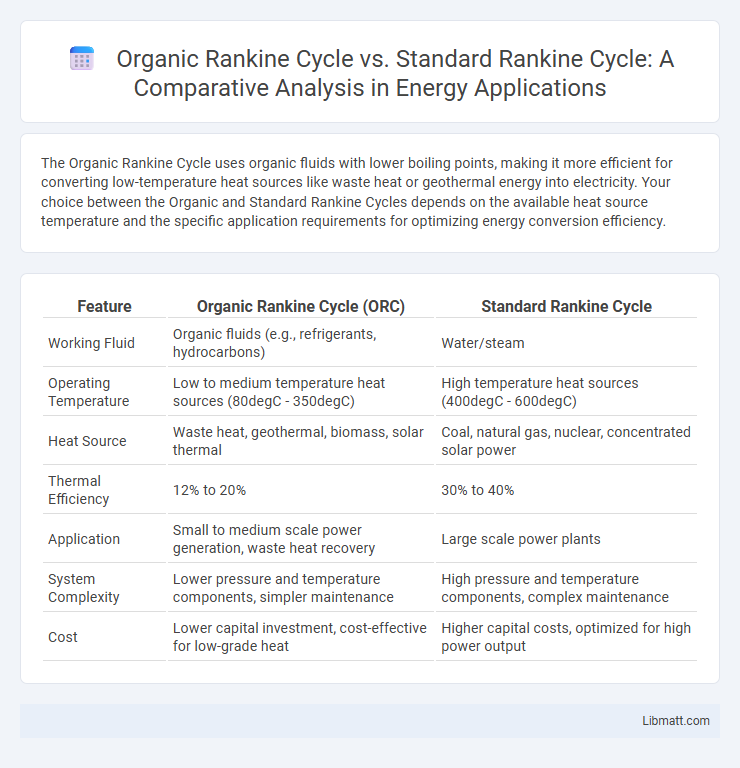

The Organic Rankine Cycle uses organic fluids with lower boiling points, making it more efficient for converting low-temperature heat sources like waste heat or geothermal energy into electricity. Your choice between the Organic and Standard Rankine Cycles depends on the available heat source temperature and the specific application requirements for optimizing energy conversion efficiency.

Table of Comparison

| Feature | Organic Rankine Cycle (ORC) | Standard Rankine Cycle |

|---|---|---|

| Working Fluid | Organic fluids (e.g., refrigerants, hydrocarbons) | Water/steam |

| Operating Temperature | Low to medium temperature heat sources (80degC - 350degC) | High temperature heat sources (400degC - 600degC) |

| Heat Source | Waste heat, geothermal, biomass, solar thermal | Coal, natural gas, nuclear, concentrated solar power |

| Thermal Efficiency | 12% to 20% | 30% to 40% |

| Application | Small to medium scale power generation, waste heat recovery | Large scale power plants |

| System Complexity | Lower pressure and temperature components, simpler maintenance | High pressure and temperature components, complex maintenance |

| Cost | Lower capital investment, cost-effective for low-grade heat | Higher capital costs, optimized for high power output |

Introduction to Rankine Cycles

The Rankine Cycle is a fundamental thermodynamic process used in power generation, converting heat energy into mechanical work, commonly using water as the working fluid. The Organic Rankine Cycle (ORC) differs by utilizing organic fluids with lower boiling points, enabling efficient energy recovery from low-temperature heat sources such as geothermal or waste heat. While the Standard Rankine Cycle operates optimally at high temperatures and pressures, the ORC expands application possibilities by adapting to variable and moderate thermal conditions.

Overview of the Standard Rankine Cycle

The Standard Rankine Cycle is a thermodynamic process used in steam power plants to convert heat energy into mechanical work by vaporizing water into steam, which then drives a turbine connected to a generator. Key components include the boiler, turbine, condenser, and feedwater pump, operating on high-pressure steam to maximize energy extraction. Efficiency depends on temperatures and pressures within the cycle, typically limited by the boiling point of water and the thermodynamic properties of steam.

Introduction to the Organic Rankine Cycle

The Organic Rankine Cycle (ORC) uses organic fluids with low boiling points to efficiently convert low-temperature heat sources into electricity, contrasting with the Standard Rankine Cycle that relies on water/steam and higher temperature heat. ORC systems excel in waste heat recovery, geothermal, and biomass applications due to their ability to operate at lower temperatures and pressures. This thermal efficiency improvement reduces operational costs and broadens feasibility for renewable and distributed energy generation.

Working Fluids: Water vs Organic Compounds

The Organic Rankine Cycle (ORC) utilizes organic compounds like refrigerants or hydrocarbons as working fluids, which have lower boiling points and higher vapor pressures compared to water used in the Standard Rankine Cycle. These organic fluids enable efficient energy recovery from low to medium temperature heat sources, enhancing overall system flexibility. In contrast, water in Standard Rankine systems offers high thermal stability and heat capacity, making it ideal for high-temperature, high-pressure steam turbines in large-scale power plants.

Thermodynamic Efficiency Comparison

The Organic Rankine Cycle (ORC) typically achieves higher thermodynamic efficiency than the Standard Rankine Cycle when operating at low to medium temperature heat sources due to its use of organic working fluids with lower boiling points. This allows ORC systems to recover waste heat more effectively, converting thermal energy into mechanical work with less thermal loss. Your choice between the two cycles should consider the specific temperature range and fluid properties to optimize overall energy conversion efficiency.

Operating Temperature and Pressure Ranges

The Organic Rankine Cycle (ORC) operates efficiently at lower temperature ranges, typically between 80degC and 350degC, utilizing organic fluids with low boiling points, whereas the Standard Rankine Cycle functions at higher temperatures, often exceeding 500degC, using water as the working fluid. ORC systems operate at lower pressure ranges, generally below 30 bar, compared to Standard Rankine Cycle pressures that can reach up to 160 bar or more. Your choice between these cycles depends on the heat source temperature and pressure constraints of your energy conversion application.

Applications in Power Generation

The Organic Rankine Cycle (ORC) is widely used for low-temperature waste heat recovery and geothermal power plants, effectively converting heat sources below 200degC into electricity. Standard Rankine Cycle systems are preferred in large-scale thermal power plants, such as coal, nuclear, and gas-fired plants, due to their efficiency at high temperatures and pressures exceeding 500degC. Your choice between these technologies depends on the heat source temperature and the scale of power generation required.

Environmental Impact and Sustainability

The Organic Rankine Cycle (ORC) offers significant environmental benefits over the Standard Rankine Cycle by utilizing organic fluids with lower boiling points, enabling efficient waste heat recovery and reducing greenhouse gas emissions. Unlike standard Rankine systems that rely on water-steam phases requiring high temperatures and pressures, ORC operates at lower thermal thresholds, minimizing thermal pollution and enhancing sustainability in renewable energy applications. The use of non-toxic and often biodegradable organic working fluids further decreases environmental risks associated with leaks or disposal, promoting a more eco-friendly energy generation process.

Economic Considerations and Cost Analysis

Economic considerations between the Organic Rankine Cycle (ORC) and the Standard Rankine Cycle (SRC) highlight significant differences in capital and operational costs due to working fluid properties and system design. ORC systems often present lower upfront costs and improved efficiency at smaller scales, leveraging organic fluids that enable lower temperature heat source utilization and reduced material requirements. Evaluating your project's budget and heat source profile is crucial to determine whether the cost savings and economic benefits of the ORC outweigh the more established SRC in large-scale, high-temperature power generation applications.

Future Trends and Technological Advancements

Future trends in Organic Rankine Cycle (ORC) technology emphasize enhanced working fluids and improved system integration to maximize efficiency at lower temperature heat sources compared to Standard Rankine Cycles. Technological advancements such as novel organic refrigerants, high-performance heat exchangers, and advanced control systems are driving the expansion of ORC applications in waste heat recovery and renewable energy sectors. Your choice of cycle will impact energy recovery capabilities and sustainability outcomes as ORC systems increasingly outperform conventional Rankine configurations in diverse industrial and power generation contexts.

Organic Rankine Cycle vs Standard Rankine Cycle Infographic

libmatt.com

libmatt.com