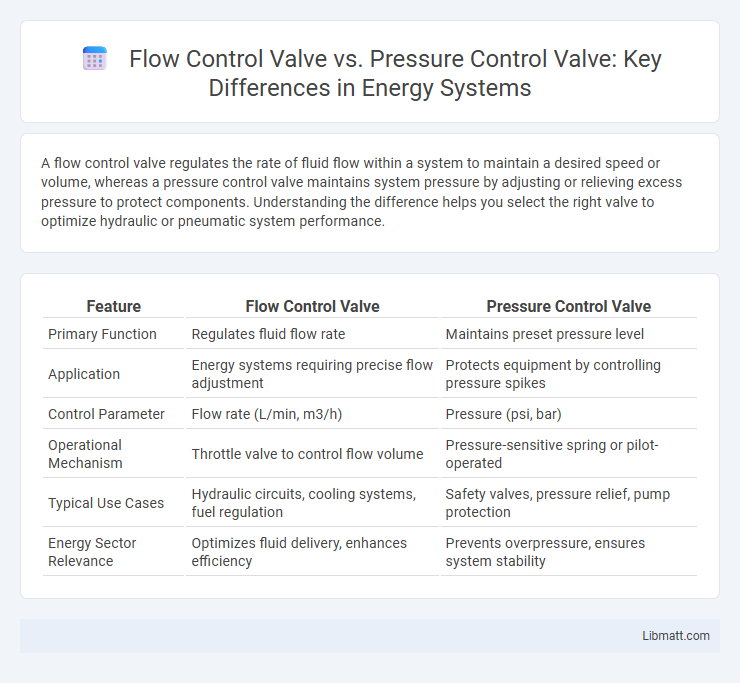

A flow control valve regulates the rate of fluid flow within a system to maintain a desired speed or volume, whereas a pressure control valve maintains system pressure by adjusting or relieving excess pressure to protect components. Understanding the difference helps you select the right valve to optimize hydraulic or pneumatic system performance.

Table of Comparison

| Feature | Flow Control Valve | Pressure Control Valve |

|---|---|---|

| Primary Function | Regulates fluid flow rate | Maintains preset pressure level |

| Application | Energy systems requiring precise flow adjustment | Protects equipment by controlling pressure spikes |

| Control Parameter | Flow rate (L/min, m3/h) | Pressure (psi, bar) |

| Operational Mechanism | Throttle valve to control flow volume | Pressure-sensitive spring or pilot-operated |

| Typical Use Cases | Hydraulic circuits, cooling systems, fuel regulation | Safety valves, pressure relief, pump protection |

| Energy Sector Relevance | Optimizes fluid delivery, enhances efficiency | Prevents overpressure, ensures system stability |

Introduction to Flow and Pressure Control Valves

Flow control valves regulate the rate and volume of fluid moving through a hydraulic or pneumatic system, ensuring consistent flow regardless of pressure changes. Pressure control valves maintain system pressure within set limits by diverting or relieving excess pressure to protect components and maintain safety. Both types of valves are essential for optimizing performance and preventing damage in industrial fluid control applications.

Fundamental Differences Between Flow and Pressure Control Valves

Flow control valves regulate the speed or flow rate of fluid within a hydraulic or pneumatic system by adjusting the passage size, ensuring consistent flow under varying pressure conditions. Pressure control valves maintain a preset pressure level by opening or closing based on the system's pressure, protecting circuits from excessive pressure and preventing damage. The fundamental difference lies in their primary function: flow control valves manage fluid velocity, while pressure control valves regulate system pressure for safety and stability.

How Flow Control Valves Work

Flow control valves regulate the speed of fluid flow by adjusting the aperture through which the fluid passes, maintaining consistent flow rates despite pressure variations. These valves use adjustable orifices or needle mechanisms to restrict flow, enabling precise control over actuator speed or process consistency. Unlike pressure control valves, which maintain system pressure, flow control valves prioritize controlling volumetric flow for optimized hydraulic and pneumatic system performance.

Operation Principles of Pressure Control Valves

Pressure control valves operate by maintaining a preset pressure level within hydraulic or pneumatic systems through modulation of flow based on pressure feedback mechanisms. They use components such as springs, diaphragms, or pistons that respond dynamically to pressure changes, adjusting valve openings to either restrict or allow fluid passage. This precise regulation prevents system damage from excessive pressure while ensuring consistent operational efficiency.

Key Applications: Flow Control vs Pressure Control Valves

Flow control valves are essential in hydraulic systems to regulate fluid flow rates, ensuring precise control in applications like conveyor systems, irrigation, and fuel injection. Pressure control valves maintain system pressure within safe limits, commonly used in hydraulic presses, water supply networks, and safety relief systems. Selecting between flow control and pressure control valves depends on whether the priority is controlling flow velocity or maintaining consistent pressure to protect equipment and optimize performance.

Advantages of Using Flow Control Valves

Flow control valves offer precise regulation of fluid flow rates, enhancing system efficiency and performance in hydraulic and pneumatic applications. These valves enable consistent flow regardless of pressure variations, reducing energy consumption and preventing equipment damage. Their ability to provide smooth and adjustable flow control supports optimized process control and improved operational safety.

Benefits of Pressure Control Valves

Pressure control valves provide precise regulation of system pressure, ensuring safety and preventing equipment damage in hydraulic and pneumatic systems. They enhance operational efficiency by maintaining consistent pressure levels, reducing energy consumption and minimizing wear on components. These valves also allow for automatic pressure adjustments under varying load conditions, improving overall system reliability and performance.

Selecting the Right Valve for Your System

Selecting the right valve for your system requires understanding the distinct functions of flow control valves and pressure control valves. Flow control valves regulate the rate of fluid flow to maintain desired system speed, crucial for hydraulic and pneumatic applications where precise flow manipulation is necessary. Pressure control valves protect system components by maintaining set pressure levels, preventing damage from overpressure and ensuring operational safety.

Common Issues and Troubleshooting

Flow control valves often face issues like leakage, clogged orifices, and improper adjustment, which can lead to inconsistent flow rates and reduced system efficiency; troubleshooting involves checking for debris, tightening connections, and recalibrating the valve settings. Pressure control valves commonly experience problems such as pressure spikes, valve chatter, or failure to maintain set pressure, usually caused by worn seals, incorrect spring tension, or contamination; resolving these issues requires inspecting and replacing seals, adjusting the spring, and cleaning the valve components. Your maintenance routine should include regular inspections and cleaning to prevent common flow and pressure valve problems and ensure optimal hydraulic system performance.

Summary: Choosing Between Flow and Pressure Control Valves

Flow control valves regulate the rate of fluid movement to maintain desired speed in hydraulic or pneumatic systems, while pressure control valves maintain system pressure within safe limits to prevent damage or failure. Selecting the right valve depends on your system's requirements: if precise speed and flow rates are critical, a flow control valve is ideal; if maintaining consistent pressure to protect components is essential, a pressure control valve is necessary. Understanding the operational parameters and system demands ensures optimal valve performance and extends equipment lifespan.

Flow Control Valve vs Pressure Control Valve Infographic

libmatt.com

libmatt.com