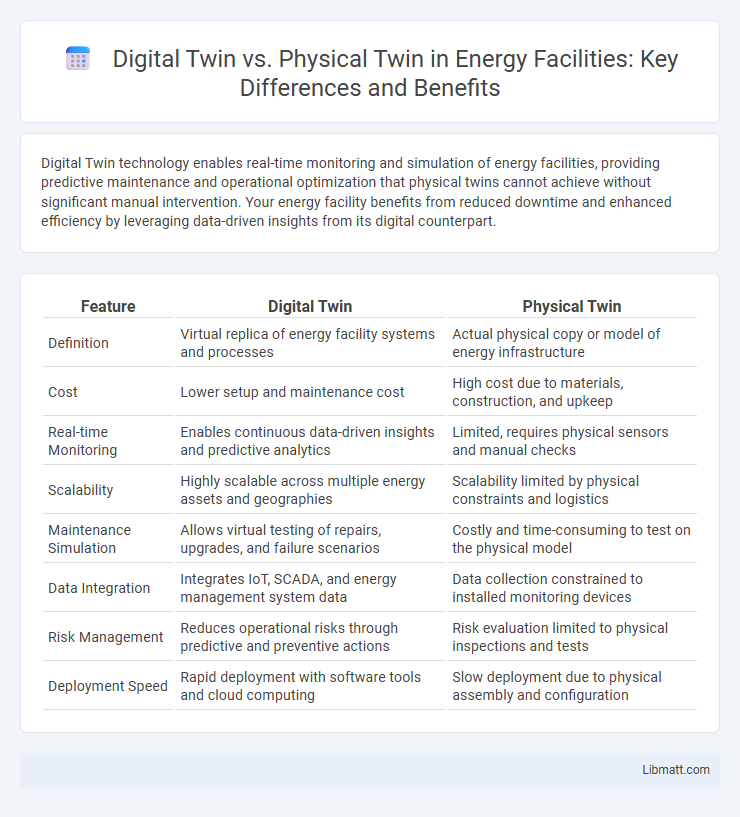

Digital Twin technology enables real-time monitoring and simulation of energy facilities, providing predictive maintenance and operational optimization that physical twins cannot achieve without significant manual intervention. Your energy facility benefits from reduced downtime and enhanced efficiency by leveraging data-driven insights from its digital counterpart.

Table of Comparison

| Feature | Digital Twin | Physical Twin |

|---|---|---|

| Definition | Virtual replica of energy facility systems and processes | Actual physical copy or model of energy infrastructure |

| Cost | Lower setup and maintenance cost | High cost due to materials, construction, and upkeep |

| Real-time Monitoring | Enables continuous data-driven insights and predictive analytics | Limited, requires physical sensors and manual checks |

| Scalability | Highly scalable across multiple energy assets and geographies | Scalability limited by physical constraints and logistics |

| Maintenance Simulation | Allows virtual testing of repairs, upgrades, and failure scenarios | Costly and time-consuming to test on the physical model |

| Data Integration | Integrates IoT, SCADA, and energy management system data | Data collection constrained to installed monitoring devices |

| Risk Management | Reduces operational risks through predictive and preventive actions | Risk evaluation limited to physical inspections and tests |

| Deployment Speed | Rapid deployment with software tools and cloud computing | Slow deployment due to physical assembly and configuration |

Understanding Digital Twins in Energy Facilities

Digital Twins in energy facilities create real-time virtual models that replicate the physical assets' performance and conditions, enabling precise monitoring and predictive maintenance. These digital replicas integrate sensor data, historical information, and advanced analytics to optimize operational efficiency and reduce downtime. By simulating scenarios, Digital Twins support informed decision-making and enhance energy management strategies without physical intervention.

Defining Physical Twins in Industrial Context

Physical twins in energy facilities refer to exact, tangible replicas of industrial equipment or systems used for real-time monitoring, performance evaluation, and maintenance. These physical counterparts enable direct experimentation and validation under actual operating conditions, providing critical insights that digital models alone cannot offer. Your ability to integrate physical twins with digital simulations enhances predictive maintenance and operational efficiency in complex energy environments.

Key Differences: Digital Twin vs Physical Twin

Digital Twin in energy facilities is a virtual replica that enables real-time monitoring, simulation, and predictive maintenance, while Physical Twin refers to the actual physical infrastructure and equipment. The key differences lie in Digital Twin's ability to analyze data remotely and optimize operations through advanced analytics, whereas Physical Twin requires on-site inspection and manual intervention. Your facility can benefit from digital twins by enhancing efficiency, reducing downtime, and improving decision-making processes without disrupting physical assets.

Core Components of a Digital Twin System

A Digital Twin system for energy facilities integrates core components such as real-time data acquisition from sensors, cloud-based data storage, and advanced analytics platforms powered by AI algorithms to simulate physical asset behavior. Digital Twins continuously mirror your physical twin's operational status, enabling predictive maintenance, performance optimization, and risk reduction through virtual testing and scenario analysis. These components ensure seamless synchronization between the digital model and the physical energy facility, enhancing decision-making accuracy and operational efficiency.

Real-world Applications of Physical Twins in Energy

Physical twins in energy facilities enable precise monitoring and maintenance by replicating equipment and system conditions, improving operational reliability and safety. These real-world applications include predictive maintenance for turbines, leak detection in pipelines, and real-time performance optimization of power grids. By leveraging sensor data and advanced simulations, physical twins reduce downtime and enhance energy efficiency across wind farms, solar parks, and thermal power plants.

Integration of Digital Twins with IoT and AI

Integration of Digital Twins with IoT and AI revolutionizes energy facility management by enabling real-time data collection and advanced analytics. Digital Twins continuously receive sensor data from IoT devices embedded within physical energy infrastructure, providing accurate simulations and predictive insights that optimize operational efficiency and reduce downtime. Your ability to leverage AI algorithms on this integrated data enhances decision-making processes, ensuring proactive maintenance and improved energy performance across the facility.

Advantages of Digital Twins for Facility Management

Digital twins offer real-time monitoring and predictive analytics for energy facilities, enabling proactive maintenance and reducing operational downtime. Your facility management benefits from enhanced data accuracy and simulation capabilities, which optimize energy efficiency and resource allocation. By leveraging digital twins, you achieve improved decision-making and cost savings compared to managing physical twins alone.

Limitations of Physical Twins in Energy Operations

Physical twins in energy operations face significant limitations due to their inflexibility and high maintenance costs, making real-time data integration and dynamic analysis challenging. These models cannot easily simulate complex scenarios or predict system behaviors under varying conditions, leading to less effective decision-making. Their scalability issues and potential downtime during physical upgrades hinder continuous operational optimization compared to digital twins.

Case Studies: Digital Twin Success Stories in Energy

Digital Twin technology has transformed energy facilities by providing real-time monitoring, predictive maintenance, and operational optimization, as demonstrated in Siemens' gas turbine projects where digital simulations reduced downtime by 20%. Shell's adoption of Digital Twins for offshore platforms enabled enhanced risk management and improved resource allocation, resulting in a 15% increase in production efficiency. Your energy asset management can benefit from these case studies, leveraging Digital Twins to surpass traditional Physical Twin limitations in cost, scalability, and data integration.

Future Trends: Bridging Digital and Physical Twins

Emerging trends in energy facilities emphasize seamless integration between digital twins and physical twins, enhancing real-time monitoring and predictive maintenance through IoT sensors and AI-driven analytics. Advanced synchronization technologies enable continuous data exchange, reducing operational downtime and optimizing energy efficiency. Future developments focus on scalable hybrid models that leverage augmented reality for immersive visualization and autonomous decision-making in smart grids.

Digital Twin vs Physical Twin (Energy Facilities) Infographic

libmatt.com

libmatt.com