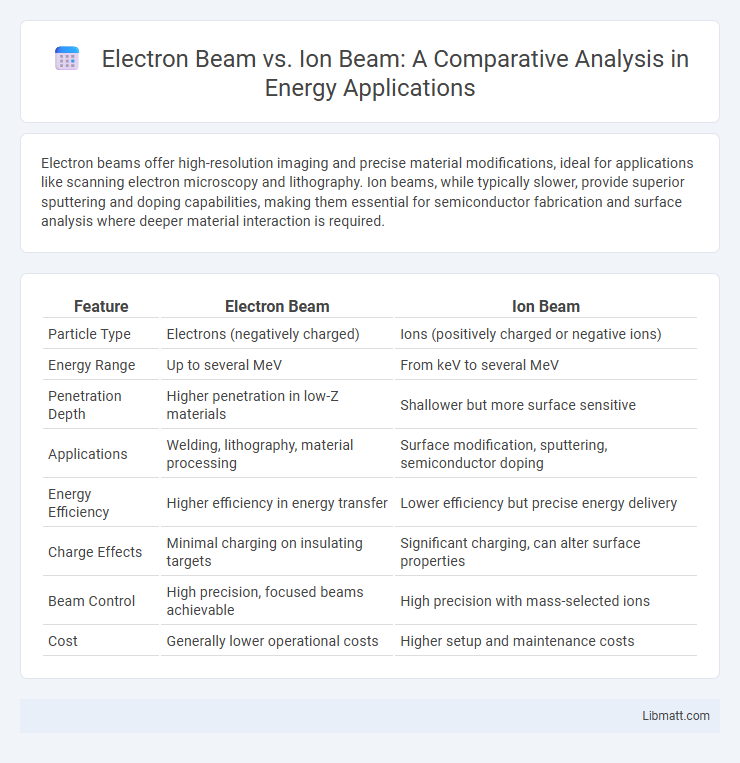

Electron beams offer high-resolution imaging and precise material modifications, ideal for applications like scanning electron microscopy and lithography. Ion beams, while typically slower, provide superior sputtering and doping capabilities, making them essential for semiconductor fabrication and surface analysis where deeper material interaction is required.

Table of Comparison

| Feature | Electron Beam | Ion Beam |

|---|---|---|

| Particle Type | Electrons (negatively charged) | Ions (positively charged or negative ions) |

| Energy Range | Up to several MeV | From keV to several MeV |

| Penetration Depth | Higher penetration in low-Z materials | Shallower but more surface sensitive |

| Applications | Welding, lithography, material processing | Surface modification, sputtering, semiconductor doping |

| Energy Efficiency | Higher efficiency in energy transfer | Lower efficiency but precise energy delivery |

| Charge Effects | Minimal charging on insulating targets | Significant charging, can alter surface properties |

| Beam Control | High precision, focused beams achievable | High precision with mass-selected ions |

| Cost | Generally lower operational costs | Higher setup and maintenance costs |

Introduction to Electron Beams and Ion Beams

Electron beams consist of focused streams of electrons accelerated to high velocities, commonly used in applications such as electron microscopy and welding due to their fine spatial resolution and high energy density. Ion beams, composed of charged ions accelerated under electric fields, are widely utilized in semiconductor fabrication, surface modification, and ion implantation because of their precise material interaction and ability to alter surface properties. Both beams enable advanced material analysis and processing by exploiting distinct particle properties and interactions with matter.

Fundamental Principles of Electron Beams

Electron beams operate by accelerating electrons through electromagnetic fields to high velocities, forming a focused stream that interacts with materials at the atomic level. Their fundamental principle involves manipulating electron wavelength and energy to generate precise imaging or modifications, commonly utilized in electron microscopy and lithography. Unlike ion beams, electron beams offer higher resolution due to shorter electron wavelengths and can achieve nanoscale precision in surface analysis and structuring.

Fundamental Principles of Ion Beams

Ion beams consist of charged particles, usually ions like gallium or argon, accelerated using electromagnetic fields to precisely target materials at the atomic level. Unlike electron beams that rely on electrons, ion beams offer higher mass and momentum, enabling more effective surface sputtering, milling, and implantation in material processing. Your choice of ion beam analysis or modification benefits from understanding these fundamental principles, as they determine resolution, penetration depth, and interaction effects crucial in semiconductor fabrication and nanotechnology.

Key Differences Between Electron and Ion Beams

Electron beams consist of high-speed electrons, offering superior resolution and minimal sample damage in imaging applications, whereas ion beams comprise positively charged ions, providing greater material sputtering and surface modification capabilities. The mass difference between electrons and ions results in electron beams having higher penetration depth but less surface interaction, while ion beams exhibit stronger surface interaction and higher implantation potential. Your choice depends on whether precise imaging or aggressive surface treatment is required, as each beam type excels in different nanofabrication and microscopy tasks.

Applications of Electron Beams in Industry and Research

Electron beams are widely used in industries for applications such as welding, surface treatment, lithography, and sterilization due to their precision and high energy density. In research, electron beams enable advanced imaging techniques like electron microscopy and facilitate material analysis at the atomic scale. Your projects can benefit from electron beam technology to achieve high-resolution manufacturing and detailed structural insights.

Applications of Ion Beams in Industry and Research

Ion beams are extensively used in industry and research for applications such as semiconductor fabrication, surface modification, and material analysis. Techniques like ion implantation enhance electrical properties of silicon wafers, while ion beam milling enables precise microfabrication in nanotechnology. In research, focused ion beams (FIB) assist in imaging, sample preparation for electron microscopy, and nanoscale device prototyping.

Advantages and Limitations of Electron Beams

Electron beams offer high resolution and precision in applications like microscopy and lithography, allowing detailed imaging and nanoscale fabrication. Their advantages include faster scanning speeds and lower damage to samples compared to ion beams. Limitations involve lower material penetration and reduced effectiveness on non-conductive samples without proper coating, which may affect your analysis or manufacturing outcomes.

Advantages and Limitations of Ion Beams

Ion beams offer superior surface modification capabilities due to their higher mass and energy, enabling precise material sputtering and implantation for semiconductor fabrication and nanostructuring. Their advantages include deeper penetration depth and enhanced control over ion energy, improving doping uniformity and defect engineering. You should consider limitations such as potential sample damage from higher ion mass and beam-induced charging effects, which can complicate analysis and require specialized vacuum conditions.

Selection Criteria: When to Use Electron or Ion Beams

Electron beams are ideal for high-resolution imaging and precise surface modifications due to their smaller wavelength and suitability for analyzing conductive materials. Ion beams excel in material sputtering, milling, and doping processes, offering superior mass and momentum transfer for modifying surface topography and composition. Your choice depends on the required penetration depth, sample sensitivity, and whether surface imaging or material alteration is the primary goal.

Future Trends in Electron and Ion Beam Technologies

Future trends in electron and ion beam technologies emphasize advances in nanoscale fabrication, enhanced imaging resolution, and increased material interaction control. Electron beam systems are evolving with higher brightness sources and improved beam coherence for precise semiconductor manufacturing and 3D nanoprinting applications. Ion beam technology trends highlight the development of focused ion beam (FIB) instruments with novel ion species and cryogenic capabilities to enable atomic-level material analysis and modification in quantum device fabrication.

Electron Beam vs Ion Beam Infographic

libmatt.com

libmatt.com