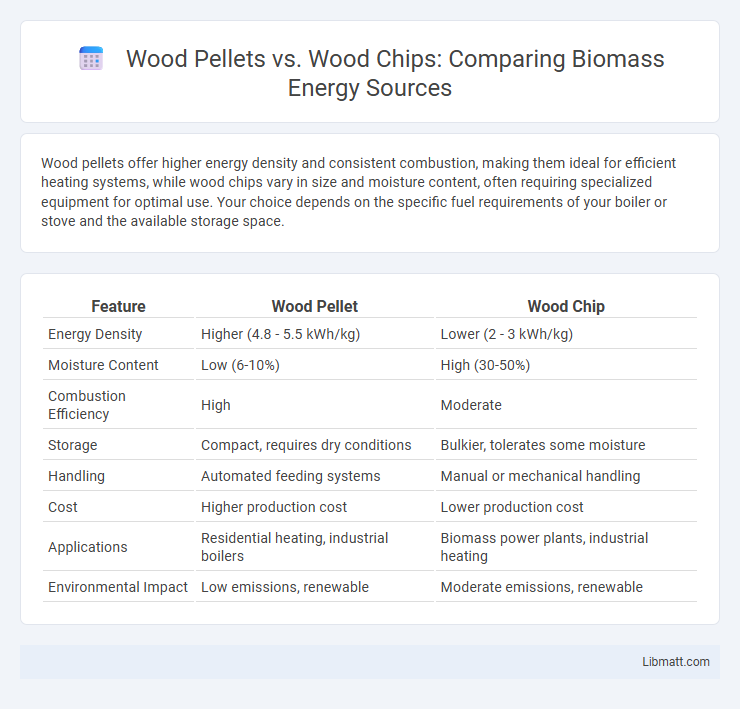

Wood pellets offer higher energy density and consistent combustion, making them ideal for efficient heating systems, while wood chips vary in size and moisture content, often requiring specialized equipment for optimal use. Your choice depends on the specific fuel requirements of your boiler or stove and the available storage space.

Table of Comparison

| Feature | Wood Pellet | Wood Chip |

|---|---|---|

| Energy Density | Higher (4.8 - 5.5 kWh/kg) | Lower (2 - 3 kWh/kg) |

| Moisture Content | Low (6-10%) | High (30-50%) |

| Combustion Efficiency | High | Moderate |

| Storage | Compact, requires dry conditions | Bulkier, tolerates some moisture |

| Handling | Automated feeding systems | Manual or mechanical handling |

| Cost | Higher production cost | Lower production cost |

| Applications | Residential heating, industrial boilers | Biomass power plants, industrial heating |

| Environmental Impact | Low emissions, renewable | Moderate emissions, renewable |

Introduction to Wood Pellet vs Wood Chip

Wood pellets are small, dense fuel units made from compressed sawdust and wood shavings, offering higher energy efficiency and consistent size for easy handling and uniform combustion. Wood chips consist of larger, irregular pieces of wood generated from chipping branches, logs, or wood waste, commonly used in biomass boilers and power plants but with lower energy density compared to pellets. Both materials serve as renewable biomass fuels, with wood pellets preferred for residential heating and industrial use due to their higher calorific value and lower moisture content.

Composition and Manufacturing Process

Wood pellets are composed of compressed sawdust and wood shavings, produced through a process involving drying, grinding, and extrusion under high pressure to form dense, uniform cylinders. Wood chips consist of larger, irregular pieces of wood, typically created by mechanically chipping branches, logs, or wood residues without extensive compression or shaping. The pellet manufacturing process enhances energy density and combustion efficiency, while wood chips retain higher moisture content and variability due to minimal processing.

Energy Efficiency Comparison

Wood pellets offer higher energy efficiency compared to wood chips due to their uniform size, density, and moisture content, resulting in more consistent combustion and greater heat output. Wood pellets typically have an energy content of around 16-18 MJ/kg, while wood chips range from 8-15 MJ/kg depending on species and moisture levels. Choosing wood pellets can optimize your heating system's performance by providing a cleaner burn and maximizing energy utilization.

Storage and Handling Differences

Wood pellets require dry, airtight storage to prevent moisture absorption and maintain combustion efficiency, whereas wood chips tolerate higher moisture content but need larger, well-ventilated storage areas to avoid mold and decomposition. Handling wood pellets involves specialized equipment like augers and pellet stoves for precise fuel delivery, while wood chips typically use front loaders and chip hoppers designed for bulk transport and combustion. Understanding these storage and handling differences helps you optimize fuel management for your heating system's performance.

Environmental Impact and Sustainability

Wood pellets have a lower moisture content and higher energy density compared to wood chips, resulting in more efficient combustion and reduced carbon emissions, enhancing environmental sustainability. Wood chips, often sourced from forestry residues and waste, support sustainable forest management by recycling biomass but tend to release more particulates and require more frequent handling. Your choice between these biomass fuels can significantly impact carbon footprint and particulate pollution, aligning with your sustainability goals.

Cost Analysis: Wood Pellet vs Wood Chip

Wood pellets typically cost more per ton than wood chips due to the additional processing required to compress the material into uniform pellets, but they offer higher energy density and more efficient combustion, potentially reducing overall fuel consumption. Wood chips are generally cheaper and more readily available, making them a cost-effective option for large-scale heating systems where storage space is less of a concern. Your choice between wood pellets and wood chips should consider not only the upfront fuel cost but also handling, storage, and boiler compatibility factors that impact long-term expenses.

Applications and Suitability

Wood pellets provide consistent energy density and are ideal for residential heating systems, small-scale boilers, and pellet stoves due to their uniform size and low moisture content. Wood chips, with variable size and higher moisture levels, are better suited for large-scale industrial boilers, biomass power plants, and pulping processes where fuel flexibility and volume handling are critical. Selection between wood pellets and wood chips depends on specific application needs, storage facilities, and combustion system compatibility.

Burning Performance and Ash Production

Wood pellets offer higher burning performance with consistent heat output and lower moisture content compared to wood chips, resulting in more efficient combustion. Wood chips tend to produce more ash due to their variable size and higher moisture, causing less predictable burning and more frequent maintenance. Choosing wood pellets can enhance your heating system's efficiency while minimizing ash disposal efforts.

Availability and Supply Chain Factors

Wood pellets offer higher availability and a more streamlined supply chain compared to wood chips, benefiting from standardized production and packaging that facilitate easier transportation and storage. Wood chips, often sourced locally, may face variability in supply due to regional wood availability and moisture content, impacting consistency and logistics. Understanding these supply chain factors can help you optimize fuel choice based on reliability and delivery efficiency.

Choosing the Right Fuel: Key Considerations

Wood pellets offer higher energy density and uniform size, providing consistent combustion and ease of storage, making them ideal for automated stoves and boilers. Wood chips vary in size and moisture content, often requiring more space and frequent handling, suitable for large-scale heating systems or biomass power plants. When choosing the right fuel, consider boiler compatibility, supply availability, cost efficiency, and moisture levels to maximize performance and reduce emissions.

Wood Pellet vs Wood Chip Infographic

libmatt.com

libmatt.com