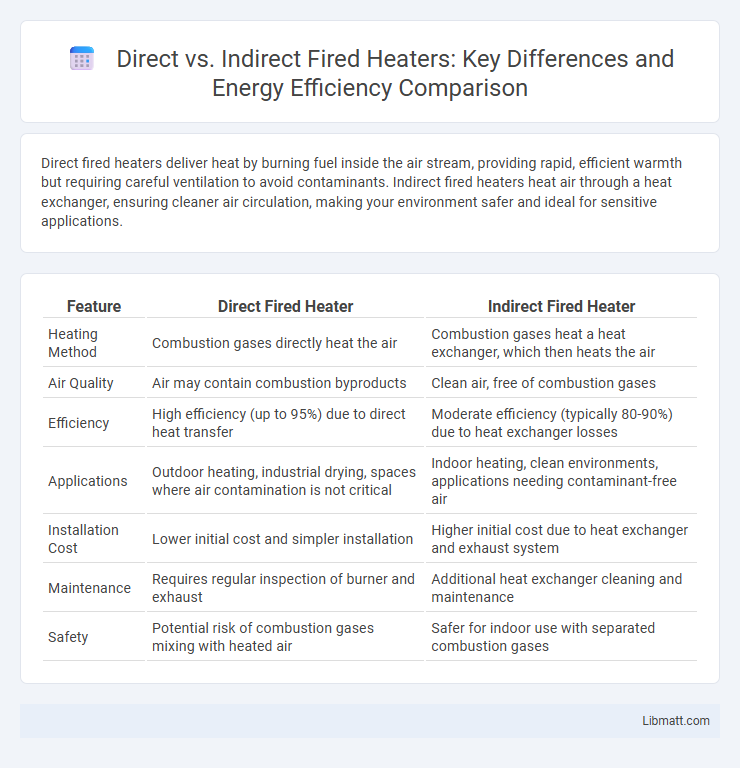

Direct fired heaters deliver heat by burning fuel inside the air stream, providing rapid, efficient warmth but requiring careful ventilation to avoid contaminants. Indirect fired heaters heat air through a heat exchanger, ensuring cleaner air circulation, making your environment safer and ideal for sensitive applications.

Table of Comparison

| Feature | Direct Fired Heater | Indirect Fired Heater |

|---|---|---|

| Heating Method | Combustion gases directly heat the air | Combustion gases heat a heat exchanger, which then heats the air |

| Air Quality | Air may contain combustion byproducts | Clean air, free of combustion gases |

| Efficiency | High efficiency (up to 95%) due to direct heat transfer | Moderate efficiency (typically 80-90%) due to heat exchanger losses |

| Applications | Outdoor heating, industrial drying, spaces where air contamination is not critical | Indoor heating, clean environments, applications needing contaminant-free air |

| Installation Cost | Lower initial cost and simpler installation | Higher initial cost due to heat exchanger and exhaust system |

| Maintenance | Requires regular inspection of burner and exhaust | Additional heat exchanger cleaning and maintenance |

| Safety | Potential risk of combustion gases mixing with heated air | Safer for indoor use with separated combustion gases |

Introduction to Fired Heaters

Fired heaters are essential industrial equipment used to heat process fluids by burning fuel to generate heat. Direct fired heaters transfer heat by exposing the process fluid directly to combustion gases, offering higher efficiency but potential contamination risks. Indirect fired heaters use a heat exchanger to separate combustion gases from the process fluid, ensuring cleaner heating suitable for sensitive applications.

What is a Direct Fired Heater?

A direct fired heater is a type of heating equipment where the fuel combustion occurs inside the heater's chamber, and the produced hot gases come into direct contact with the material or air being heated. This design allows for faster heat transfer and higher efficiency compared to indirect systems. Direct fired heaters are commonly used in industrial processes requiring rapid temperature increase and outdoor heating applications.

What is an Indirect Fired Heater?

An indirect fired heater transfers heat to a process fluid through a heat exchanger, ensuring combustion gases do not mix with the fluid, which maintains purity and prevents contamination. This type of heater is ideal for applications requiring clean, controlled heating environments, such as in chemical processing or HVAC systems. Efficiency and safety are enhanced by isolating combustion products from the heated medium, making indirect fired heaters suitable for sensitive or hazardous operations.

Key Differences: Direct vs Indirect Fired Heaters

Direct fired heaters transfer heat by mixing the combustion gases directly with the air or fluid being heated, offering rapid heating and high efficiency. Indirect fired heaters use a heat exchanger to separate combustion gases from the heated medium, providing cleaner air output and preventing contamination. Key differences include combustion gas exposure, efficiency levels, maintenance requirements, and suitability for various applications where air quality and safety are critical.

Applications of Direct Fired Heaters

Direct fired heaters are commonly used in industrial processes requiring rapid heat transfer, such as in petrochemical refining, natural gas processing, and power generation. These heaters efficiently heat air or gases by directly mixing fuel combustion products with the process fluid, making them ideal for drying, curing, and thermal oxidation applications. Your operations benefit from their high thermal efficiency and straightforward installation in settings where precise temperature control is less critical.

Applications of Indirect Fired Heaters

Indirect fired heaters are ideal for applications requiring clean, contaminant-free air or gas, such as in pharmaceutical manufacturing, food processing, and electronics production. They are commonly used in spaces where combustion byproducts must be kept separate from the heated air, including cleanrooms and paint booths. Your choice of an indirect fired heater ensures precise temperature control and improved air quality critical for sensitive industrial processes.

Efficiency Comparison: Direct vs Indirect Fired

Direct fired heaters typically achieve higher efficiency by directly transferring heat to the process fluid, minimizing heat loss. Indirect fired heaters use a heat exchanger, which reduces potential contamination but results in lower thermal efficiency due to heat transfer limitations. The efficiency of direct fired systems can exceed 90%, whereas indirect fired heaters generally operate between 75% and 85% efficiency.

Safety Considerations for Both Heater Types

Direct fired heaters expose combustion gases directly to the heated air, necessitating stringent ventilation to prevent toxic exposure and ensure safe operation. Indirect fired heaters separate combustion gases with a heat exchanger, significantly reducing the risk of carbon monoxide poisoning and making them safer for enclosed spaces. Your safety depends on selecting the appropriate heater type for the environment and adhering to proper installation and maintenance protocols.

Choosing the Right Heater for Your Needs

Direct fired heaters deliver rapid heat by mixing combustion gases directly with the airflow, making them highly efficient for open spaces and quick heating needs. Indirect fired heaters use a heat exchanger to separate combustion gases from the airflow, providing cleaner, contaminant-free air ideal for enclosed environments or sensitive applications. Choosing the right heater for your needs depends on factors such as ventilation availability, air quality requirements, and heating speed, ensuring optimal performance and safety.

Conclusion: Selecting Between Direct and Indirect Fired Heaters

Choosing between direct and indirect fired heaters depends on the specific heating application and environment requirements; direct fired heaters offer higher efficiency and rapid heat transfer by directly contacting the air with combustion gases, ideal for open or outdoor spaces. Indirect fired heaters provide cleaner, contaminant-free air by separating combustion gases from the heated air using a heat exchanger, making them suitable for indoor or sensitive environments. Assessing factors like air quality, energy efficiency, application setting, and operational costs is essential for selecting the appropriate heater type.

Direct vs Indirect Fired Heater Infographic

libmatt.com

libmatt.com