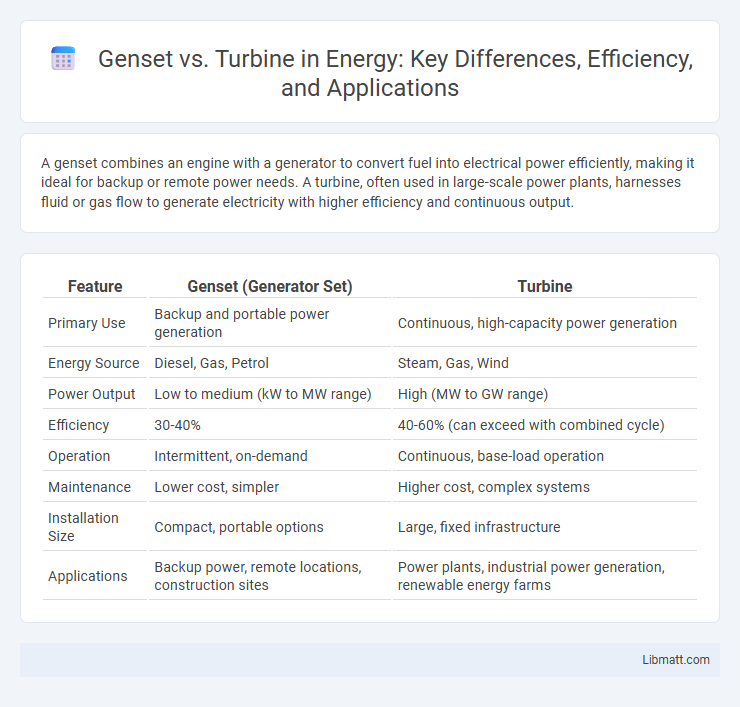

A genset combines an engine with a generator to convert fuel into electrical power efficiently, making it ideal for backup or remote power needs. A turbine, often used in large-scale power plants, harnesses fluid or gas flow to generate electricity with higher efficiency and continuous output.

Table of Comparison

| Feature | Genset (Generator Set) | Turbine |

|---|---|---|

| Primary Use | Backup and portable power generation | Continuous, high-capacity power generation |

| Energy Source | Diesel, Gas, Petrol | Steam, Gas, Wind |

| Power Output | Low to medium (kW to MW range) | High (MW to GW range) |

| Efficiency | 30-40% | 40-60% (can exceed with combined cycle) |

| Operation | Intermittent, on-demand | Continuous, base-load operation |

| Maintenance | Lower cost, simpler | Higher cost, complex systems |

| Installation Size | Compact, portable options | Large, fixed infrastructure |

| Applications | Backup power, remote locations, construction sites | Power plants, industrial power generation, renewable energy farms |

Introduction to Genset and Turbine Technology

Genset technology combines an engine with an electric generator to produce reliable electricity, commonly used for backup power and remote locations. Turbine technology converts kinetic energy from fluids such as steam, water, or air into mechanical energy, driving generators for large-scale power generation with high efficiency. Understanding these technologies helps you choose the right power solution based on capacity, efficiency, and application requirements.

How Gensets Work: Basic Principles

Gensets generate electricity by converting mechanical energy from an engine into electrical power through an alternator, relying on fuel combustion to drive the engine. Turbines operate by harnessing kinetic energy from fluid flow, such as steam, gas, or water, spinning blades connected to a generator to produce electricity. Understanding these mechanisms helps you choose the right power solution based on efficiency, fuel type, and application needs.

Understanding Turbine Generators

Turbine generators convert mechanical energy from steam, gas, or water turbines into electrical power, offering high efficiency for large-scale energy production. Unlike gensets, which combine an internal combustion engine with a generator for flexible, portable power, turbine generators excel in continuous, high-capacity applications like power plants. Understanding turbine generators helps you assess their suitability for industrial, utility, or renewable energy projects requiring reliable, high-output electricity.

Efficiency Comparison: Genset vs Turbine

Gensets typically offer higher efficiency at partial loads, making them ideal for variable power demands, while turbines excel in efficiency at continuous high power output due to their streamlined combustion process. The thermal efficiency of modern gas turbines can reach up to 40%, whereas diesel gensets usually range between 30-35%. Your choice depends on operational load profiles and fuel availability to maximize overall energy efficiency.

Fuel Types and Consumption

Gensets commonly run on diesel, gasoline, or natural gas, known for efficiency in small to medium power outputs while consuming more fuel per kilowatt-hour compared to turbines. Turbines primarily use natural gas or liquid fuels like kerosene, delivering higher fuel efficiency at large scales with lower fuel consumption rates for continuous, high-demand operations. Your choice hinges on fuel availability, cost, and the scale of power needed, as turbines are optimal for large, steady loads and gensets suit variable or emergency power needs.

Installation and Maintenance Requirements

Gensets require flexible installation options with moderate space and can be quickly deployed in various environments, while turbines demand precise site preparation and substantial infrastructure due to their larger size and complexity. Maintenance for gensets involves routine checks of fuel systems, oil levels, and filters, making them suitable for decentralized power generation, whereas turbines require specialized technicians for regular inspections of blades, bearings, and lubrication systems to ensure optimal performance and longevity. The overall maintenance costs for turbines are typically higher compared to gensets because of the advanced technology and stringent operational standards involved.

Environmental Impact and Emissions

Gensets typically produce higher emissions due to reliance on fossil fuels like diesel, resulting in greater greenhouse gases and particulate matter compared to turbines. Turbines, especially those powered by natural gas or renewable sources, generate lower carbon footprints and reduced air pollutants, contributing to improved air quality. Choosing the right system can significantly impact your environmental goals by minimizing harmful emissions and promoting sustainable energy use.

Cost Analysis: Initial and Operational Expenses

Gensets typically have lower initial costs compared to turbines, making them more accessible for small to medium power needs. Operational expenses for gensets include fuel consumption and routine maintenance, which can add up over time due to lower efficiency and frequent servicing. Turbines, although costly upfront due to advanced technology and installation requirements, offer lower long-term operational costs through higher efficiency and reduced fuel usage.

Applications and Industry Use Cases

Gensets are widely used in construction sites, remote locations, and emergency backup power for hospitals due to their portability and reliability. Turbines dominate large-scale industrial applications such as power plants, oil and gas refineries, and aviation, where continuous and high-capacity energy generation is required. Your choice between a genset and turbine depends on the scale, operational duration, and energy demand of your specific industry application.

Choosing the Right Power Solution

Choosing the right power solution involves evaluating gensets and turbines based on efficiency, fuel type, and application needs. Gensets excel in portable, backup, and small to medium power generation with flexibility in fuel options like diesel, natural gas, or biogas. Turbines, typically used in large-scale, continuous power production, offer higher efficiency in steady-state operations and are suitable for industrial and utility-scale projects.

Genset vs Turbine Infographic

libmatt.com

libmatt.com