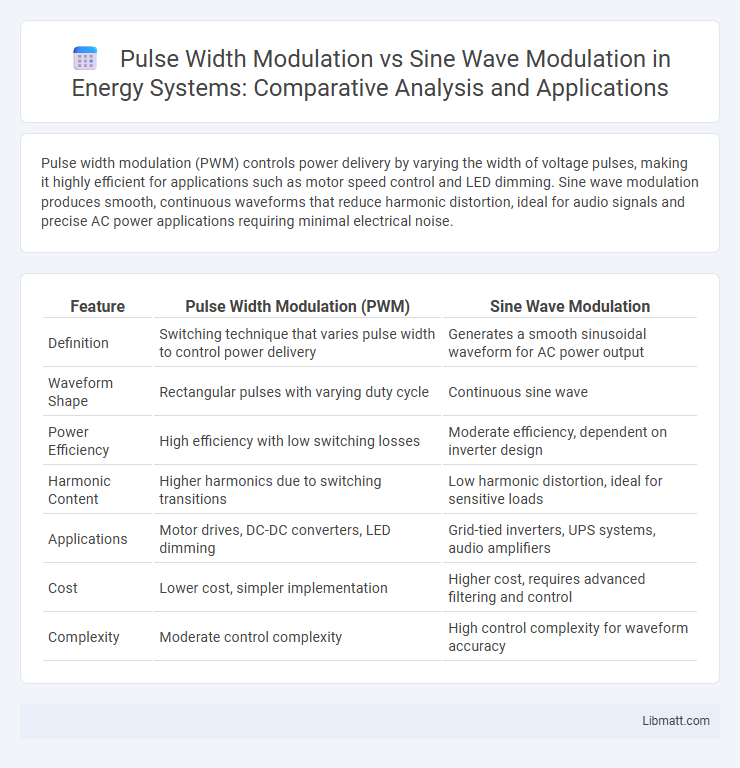

Pulse width modulation (PWM) controls power delivery by varying the width of voltage pulses, making it highly efficient for applications such as motor speed control and LED dimming. Sine wave modulation produces smooth, continuous waveforms that reduce harmonic distortion, ideal for audio signals and precise AC power applications requiring minimal electrical noise.

Table of Comparison

| Feature | Pulse Width Modulation (PWM) | Sine Wave Modulation |

|---|---|---|

| Definition | Switching technique that varies pulse width to control power delivery | Generates a smooth sinusoidal waveform for AC power output |

| Waveform Shape | Rectangular pulses with varying duty cycle | Continuous sine wave |

| Power Efficiency | High efficiency with low switching losses | Moderate efficiency, dependent on inverter design |

| Harmonic Content | Higher harmonics due to switching transitions | Low harmonic distortion, ideal for sensitive loads |

| Applications | Motor drives, DC-DC converters, LED dimming | Grid-tied inverters, UPS systems, audio amplifiers |

| Cost | Lower cost, simpler implementation | Higher cost, requires advanced filtering and control |

| Complexity | Moderate control complexity | High control complexity for waveform accuracy |

Introduction to Modulation Techniques

Pulse width modulation (PWM) and sine wave modulation are fundamental techniques used to control power delivery in electrical systems. PWM adjusts the width of voltage pulses to regulate motor speed and brightness efficiently, while sine wave modulation generates smooth, continuous waveforms ideal for minimizing harmonic distortion in AC power applications. Your choice between these methods depends on the specific performance, efficiency, and harmonic quality requirements of your application.

What is Pulse Width Modulation (PWM)?

Pulse Width Modulation (PWM) is a digital technique that controls the power delivered to electrical devices by varying the width of voltage pulses while keeping the frequency constant. PWM efficiently regulates motor speed, LED brightness, and power inverters by switching the signal on and off rapidly, creating a square wave with adjustable pulse duration. Your applications benefit from PWM's precise control and high efficiency compared to sine wave modulation, which produces smoother waveform output but is more complex to implement.

Understanding Sine Wave Modulation

Sine wave modulation produces a smooth, continuous waveform essential for applications requiring low harmonic distortion and efficient power delivery. Unlike pulse width modulation (PWM), sine wave modulation generates output signals that closely replicate the ideal sinusoidal shape, improving motor performance and reducing electromagnetic interference. Your choice between pulse width modulation and sine wave modulation depends on the need for signal purity and the specific requirements of your electronic or motor control system.

Key Differences Between PWM and Sine Wave Modulation

Pulse Width Modulation (PWM) generates signals by varying the duty cycle of rectangular pulses, offering high efficiency and precise control suited for power electronics and motor drives. In contrast, Sine Wave Modulation produces smooth, continuous waveforms that closely mimic the natural sinusoidal output required for applications involving audio signals or AC power delivery. Your choice between PWM and Sine Wave Modulation depends on the need for waveform quality, harmonic distortion levels, and system complexity.

Efficiency Comparison: PWM vs Sine Wave

Pulse Width Modulation (PWM) offers higher efficiency in power conversion compared to sine wave modulation, as it reduces switching losses by rapidly switching between fully on and off states. Sine wave modulation provides smoother output with less harmonic distortion but often results in lower efficiency due to continuous modulation and higher switching losses. Your choice depends on whether you prioritize energy efficiency or power quality in applications like motor drives or inverters.

Harmonic Distortion and Signal Quality

Pulse Width Modulation (PWM) typically produces higher harmonic distortion due to rapid switching transients, resulting in a more complex and noisier signal spectrum. Sine wave modulation generates a smoother, lower-distortion output with cleaner signal quality, ideal for applications requiring precise waveform reproduction. The reduced harmonic content in sine wave modulation improves overall system efficiency and minimizes electromagnetic interference compared to PWM.

Applications of Pulse Width Modulation

Pulse Width Modulation (PWM) is widely used in motor control, power delivery, and signal processing due to its high efficiency and precise power regulation. Unlike sine wave modulation, PWM effectively controls the speed and torque of electric motors in applications such as robotics, electric vehicles, and HVAC systems. You benefit from PWM's ability to minimize power loss while maintaining accurate voltage and current levels in these demanding industrial and consumer electronics environments.

Use Cases for Sine Wave Modulation

Sine wave modulation is commonly used in applications requiring smooth, continuous signals such as audio amplification, power inverters, and communication systems where signal fidelity is critical. This modulation technique is ideal for reducing harmonic distortion and electromagnetic interference, making it suitable for sensitive electronic devices and high-quality audio equipment. Your systems will benefit from sine wave modulation when precision and low noise are essential for optimal performance.

Advantages and Disadvantages of Each Modulation

Pulse width modulation (PWM) offers high efficiency and precise control over power delivery, making it ideal for motor drives and LED dimming, but it can introduce high-frequency noise and electromagnetic interference. Sine wave modulation produces smoother and cleaner output with reduced harmonic distortion, enhancing performance in audio and power systems, yet it requires more complex circuitry and may have lower efficiency under certain conditions. Choosing between PWM and sine wave modulation depends on the specific application requirements, such as noise tolerance, power efficiency, and control complexity.

Choosing the Right Modulation Technique for Your Application

Pulse width modulation (PWM) offers precise control over power delivery and efficiency, making it ideal for motor drives and digital signal applications requiring rapid switching. Sine wave modulation provides smoother output with reduced harmonic distortion, better suited for audio systems and sensitive electronics demanding clean and stable signals. Selecting the appropriate technique depends on factors like application sensitivity, required signal fidelity, and power efficiency.

Pulse width modulation vs Sine wave modulation Infographic

libmatt.com

libmatt.com