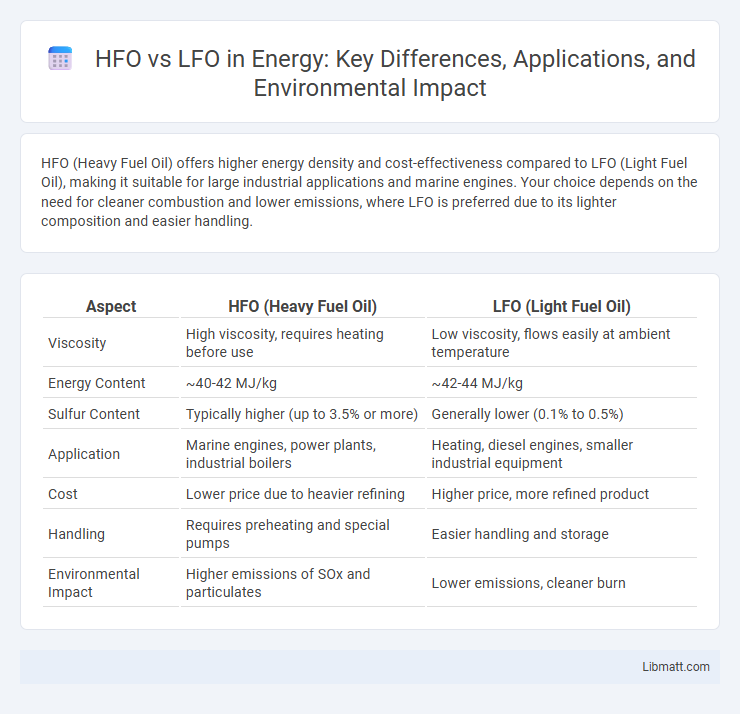

HFO (Heavy Fuel Oil) offers higher energy density and cost-effectiveness compared to LFO (Light Fuel Oil), making it suitable for large industrial applications and marine engines. Your choice depends on the need for cleaner combustion and lower emissions, where LFO is preferred due to its lighter composition and easier handling.

Table of Comparison

| Aspect | HFO (Heavy Fuel Oil) | LFO (Light Fuel Oil) |

|---|---|---|

| Viscosity | High viscosity, requires heating before use | Low viscosity, flows easily at ambient temperature |

| Energy Content | ~40-42 MJ/kg | ~42-44 MJ/kg |

| Sulfur Content | Typically higher (up to 3.5% or more) | Generally lower (0.1% to 0.5%) |

| Application | Marine engines, power plants, industrial boilers | Heating, diesel engines, smaller industrial equipment |

| Cost | Lower price due to heavier refining | Higher price, more refined product |

| Handling | Requires preheating and special pumps | Easier handling and storage |

| Environmental Impact | Higher emissions of SOx and particulates | Lower emissions, cleaner burn |

Introduction to HFO and LFO

High Fuel Oil (HFO) is a viscous residual fuel derived from crude oil refining, commonly used in large marine engines and power plants due to its high energy content and cost-effectiveness. Low Fuel Oil (LFO), also known as marine diesel oil or distillate fuel oil, is a lighter, less viscous fuel with lower sulfur content, offering cleaner combustion and easier handling. The choice between HFO and LFO depends on engine design, environmental regulations, and operational requirements.

Defining Heavy Fuel Oil (HFO)

Heavy Fuel Oil (HFO) is a viscous, high-density residual fuel derived from crude oil refining, characterized by its high sulfur content and lower cost compared to lighter fuels. It is commonly used in marine engines and power plants due to its energy density but requires specialized handling and combustion systems. Understanding the properties of HFO is crucial for optimizing your fuel choice in industrial and maritime applications.

Understanding Light Fuel Oil (LFO)

Light Fuel Oil (LFO) is a refined petroleum product used primarily in industrial heating and marine engines due to its lower viscosity and higher combustion efficiency compared to Heavy Fuel Oil (HFO). LFO typically contains fewer impurities and sulfur content, resulting in cleaner emissions and easier handling during storage and transportation. Its balancing characteristics make LFO a preferred choice for applications requiring quicker ignition and reduced environmental impact.

Chemical Composition and Properties

HFO (Heavy Fuel Oil) contains a higher concentration of residual hydrocarbons and sulfur compounds compared to LFO (Light Fuel Oil), which is composed mainly of lighter, more volatile hydrocarbons with lower sulfur content. The chemical composition of HFO results in higher viscosity and density, requiring heating for efficient combustion, while LFO's lower viscosity and sulfur levels enhance its cleaner-burning properties and ease of handling. Understanding these differences in chemical composition and properties allows Your engine or industrial process to optimize fuel selection for performance and environmental compliance.

Energy Efficiency Comparison

Heavy Fuel Oil (HFO) and Light Fuel Oil (LFO) differ significantly in energy efficiency, with LFO generally providing higher combustion efficiency due to its lower viscosity and sulfur content. This results in reduced engine deposits and improved fuel atomization, enhancing thermal efficiency and lowering specific fuel consumption. Despite HFO's higher calorific value, LFO's superior combustion characteristics often lead to better overall energy utilization in marine and industrial engines.

Environmental Impact and Emissions

HFO (Heavy Fuel Oil) produces higher levels of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter, contributing significantly to air pollution and acid rain. LFO (Light Fuel Oil) contains fewer impurities, resulting in lower emissions and a reduced environmental footprint compared to HFO. Choosing LFO for your operations can help minimize greenhouse gas emissions and comply with stricter environmental regulations.

Cost Analysis: HFO vs LFO

Heavy Fuel Oil (HFO) generally offers a lower initial purchase price compared to Light Fuel Oil (LFO), making it a cost-effective option for large-scale industrial use. However, HFO requires more complex handling and maintenance, potentially increasing operational expenses over time, while LFO's higher combustion efficiency can lead to lower fuel consumption and reduced emissions costs. Your choice between HFO and LFO should consider both upfront fuel costs and long-term maintenance and efficiency factors to optimize overall expenditure.

Applications and Industry Usage

Heavy Fuel Oil (HFO) is predominantly used in large-scale marine engines, power plants, and industrial boilers due to its high energy content and cost-efficiency, especially in shipping and heavy industries. Light Fuel Oil (LFO) finds extensive application in residential heating, smaller industrial furnaces, and diesel generators, offering cleaner combustion and easier handling. The industrial usage of HFO is favored in sectors requiring high thermal output, while LFO is preferred for applications needing quick ignition and lower emissions.

Regulatory Compliance and Restrictions

HFO (Heavy Fuel Oil) faces stricter regulatory compliance and more extensive restrictions compared to LFO (Light Fuel Oil) due to its higher sulfur content and greater environmental impact. International regulations like IMO 2020 limit sulfur emissions from HFO, forcing ships to either use scrubbers or switch to cleaner fuels such as LFO or IMO-compliant alternatives. Your choice between HFO and LFO will significantly influence adherence to emissions standards and operational eligibility in emission control areas.

Future Trends in Fuel Oil Technologies

Future trends in fuel oil technologies emphasize the transition from heavy low sulfur fuel oil (LFO) to cleaner heavy fuel oil (HFO) blends integrated with advanced emission reduction systems. Innovations in HFO formulations aim to reduce sulfur oxide (SOx) and nitrogen oxide (NOx) emissions while enhancing combustion efficiency for maritime and industrial engines. Emerging digital monitoring and control technologies enable optimized operational performance and compliance with the International Maritime Organization's (IMO) 2020 sulfur cap regulations.

HFO vs LFO Infographic

libmatt.com

libmatt.com