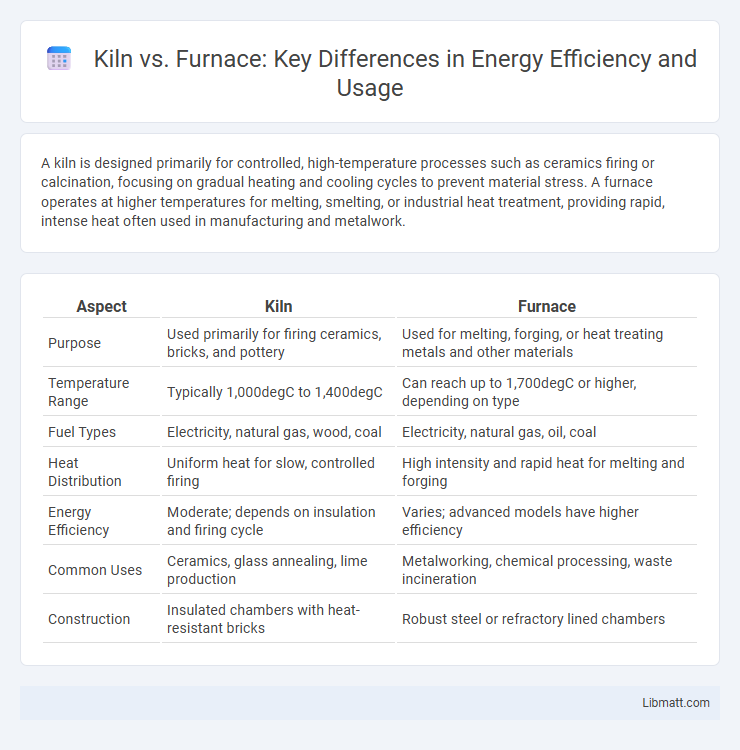

A kiln is designed primarily for controlled, high-temperature processes such as ceramics firing or calcination, focusing on gradual heating and cooling cycles to prevent material stress. A furnace operates at higher temperatures for melting, smelting, or industrial heat treatment, providing rapid, intense heat often used in manufacturing and metalwork.

Table of Comparison

| Aspect | Kiln | Furnace |

|---|---|---|

| Purpose | Used primarily for firing ceramics, bricks, and pottery | Used for melting, forging, or heat treating metals and other materials |

| Temperature Range | Typically 1,000degC to 1,400degC | Can reach up to 1,700degC or higher, depending on type |

| Fuel Types | Electricity, natural gas, wood, coal | Electricity, natural gas, oil, coal |

| Heat Distribution | Uniform heat for slow, controlled firing | High intensity and rapid heat for melting and forging |

| Energy Efficiency | Moderate; depends on insulation and firing cycle | Varies; advanced models have higher efficiency |

| Common Uses | Ceramics, glass annealing, lime production | Metalworking, chemical processing, waste incineration |

| Construction | Insulated chambers with heat-resistant bricks | Robust steel or refractory lined chambers |

Introduction to Kiln and Furnace

A kiln is a high-temperature oven primarily used for firing ceramics, bricks, and pottery, employing controlled heat to harden materials through processes like sintering and vitrification. A furnace operates at even higher temperatures and is designed for smelting metals, heat treatment, and industrial-scale thermal processes, facilitating chemical reactions such as melting and alloying. Both devices utilize thermal energy but differ significantly in function, design, and temperature range based on their specific applications.

Key Differences Between Kiln and Furnace

Kilns operate at moderate temperatures primarily for firing ceramics, bricks, and pottery, while furnaces reach much higher temperatures used for melting metals and industrial processes. Kilns rely on controlled heating to achieve consistent material transformation, whereas furnaces focus on intense heat to alter material states rapidly. Fuel types for kilns often include wood, gas, or electricity, contrasting with furnaces that typically use gas, oil, or electric elements for sustained high-temperature output.

Common Uses of Kilns

Kilns are primarily used for firing ceramics, pottery, and bricks, where controlled high temperatures are essential for hardening and glazing materials. They also play a crucial role in the production of glass and in the calcination of minerals for industrial applications. Unlike furnaces, kilns provide a consistent, gradual heating process ideal for delicate materials requiring precise temperature control.

Common Applications of Furnaces

Furnaces are widely used in industrial processes such as metal smelting, glass production, and heat treatment of materials due to their capability to reach extremely high temperatures efficiently. You will often find furnaces integral in manufacturing sectors requiring precise thermal processing, including chemical production and ceramics firing. Their design supports continuous operation, making them ideal for large-scale applications where consistent heat distribution is critical.

Temperature Capabilities: Kiln vs Furnace

Kilns typically operate at temperatures ranging from 1,000 to 2,400 degrees Fahrenheit, ideal for ceramics, glass, and metal annealing processes. Furnaces can reach much higher temperatures, often exceeding 3,000 degrees Fahrenheit, suitable for industrial applications like metal smelting and heat treatment. Understanding these temperature capabilities helps you select the right equipment based on the heat intensity required for your specific material processing needs.

Energy Efficiency Comparison

Kilns and furnaces differ significantly in energy efficiency based on their design and application; kilns, primarily used for ceramics and pottery, typically operate at lower temperatures and utilize insulation techniques to retain heat, resulting in moderate energy consumption. Furnaces, designed for higher temperature industrial processes such as metal smelting or heat treatment, often incorporate advanced combustion systems and heat recovery units that enhance fuel utilization and overall efficiency. Comparing energy efficiency, modern furnaces generally achieve higher thermal efficiency rates, sometimes exceeding 85%, whereas kilns often range between 50% and 70%, depending on construction and fuel type.

Material Types Processed

Kilns are primarily designed for processing ceramic, clay, and pottery materials through controlled high-temperature heating, essential for hardening and glazing. Furnaces handle a broader range of materials, including metals, glass, and industrial chemicals, typically involving melting or smelting. Your choice depends on the specific material type and thermal process required, with kilns suited for ceramics and furnaces for metal and glass applications.

Maintenance and Durability

Kilns require regular maintenance to prevent thermal cracks and ensure consistent temperature control, with ceramic insulation needing periodic replacement to maintain efficiency. Furnaces, especially industrial-grade models, are built for durability with robust steel construction and advanced refractory linings, minimizing maintenance frequency but requiring occasional inspection of burners and electrical components. Your choice should consider whether you prioritize the lower upkeep of a durable furnace or the specialized care a kiln demands for precision firing.

Cost Analysis: Kiln vs Furnace

A kiln typically consumes less energy than a furnace, resulting in lower operational costs for prolonged use, especially in ceramics and pottery industries. Furnaces, while offering higher temperature ranges suited for metalworking and industrial applications, often incur higher initial installation and maintenance expenses. Your decision should factor in the specific energy efficiency, upfront investment, and long-term expenses aligned with your production needs.

Choosing the Right Option for Your Needs

When deciding between a kiln and a furnace, consider the specific temperatures and materials involved in your process, as kilns typically operate at lower temperatures suited for ceramics and pottery, while furnaces handle higher heat for metals and industrial applications. Your choice depends on the precision, duration, and atmosphere required, with kilns offering controlled environments for gradual heating and furnaces providing rapid, intense heat ideal for melting or smelting. Evaluating these factors ensures you select the right equipment that meets your production needs and efficiency goals.

Kiln vs Furnace Infographic

libmatt.com

libmatt.com