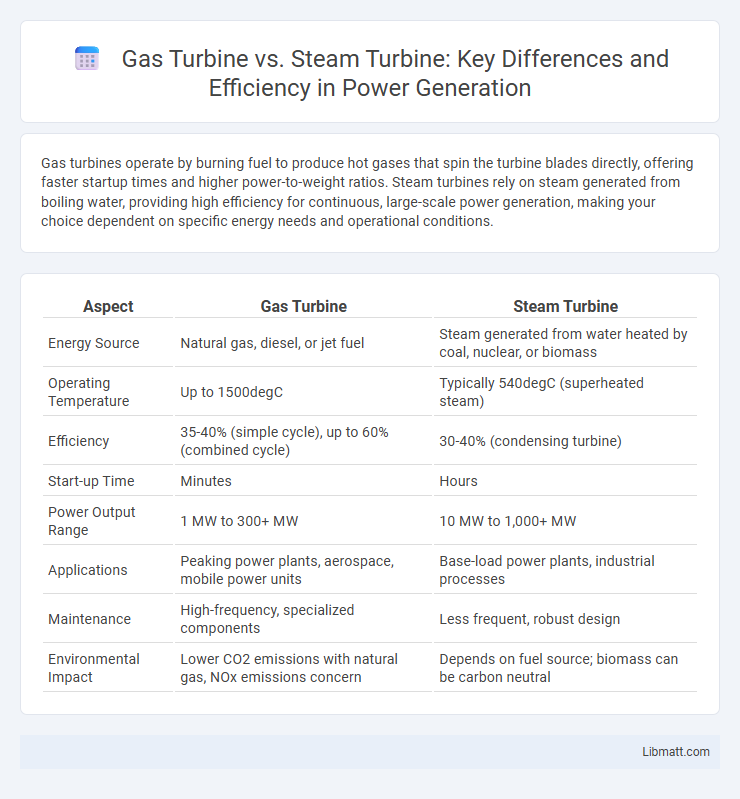

Gas turbines operate by burning fuel to produce hot gases that spin the turbine blades directly, offering faster startup times and higher power-to-weight ratios. Steam turbines rely on steam generated from boiling water, providing high efficiency for continuous, large-scale power generation, making your choice dependent on specific energy needs and operational conditions.

Table of Comparison

| Aspect | Gas Turbine | Steam Turbine |

|---|---|---|

| Energy Source | Natural gas, diesel, or jet fuel | Steam generated from water heated by coal, nuclear, or biomass |

| Operating Temperature | Up to 1500degC | Typically 540degC (superheated steam) |

| Efficiency | 35-40% (simple cycle), up to 60% (combined cycle) | 30-40% (condensing turbine) |

| Start-up Time | Minutes | Hours |

| Power Output Range | 1 MW to 300+ MW | 10 MW to 1,000+ MW |

| Applications | Peaking power plants, aerospace, mobile power units | Base-load power plants, industrial processes |

| Maintenance | High-frequency, specialized components | Less frequent, robust design |

| Environmental Impact | Lower CO2 emissions with natural gas, NOx emissions concern | Depends on fuel source; biomass can be carbon neutral |

Introduction to Gas and Steam Turbines

Gas turbines convert energy by burning fuel to produce hot gases that spin turbine blades, commonly used in power plants and aircraft engines for rapid startup and high power-to-weight ratios. Steam turbines operate by expanding high-pressure steam across blades, typically found in traditional power generation with efficient energy transfer from steam produced by boilers. Your choice depends on factors like fuel availability, efficiency requirements, and operational flexibility in energy systems.

Fundamental Operating Principles

Gas turbines operate on the Brayton cycle, where compressed air is mixed with fuel and combusted to produce high-temperature, high-pressure gas that drives the turbine blades. Steam turbines function on the Rankine cycle, utilizing steam generated from boiling water to expand through turbine blades, converting thermal energy from the steam into mechanical work. The key distinction lies in the working fluid: gas turbines use combustion gases, while steam turbines rely on steam, affecting efficiency, startup time, and application suitability.

Energy Efficiency Comparison

Gas turbines typically achieve thermal efficiencies between 30% and 40%, with combined cycle configurations boosting efficiency up to 60%. Steam turbines, especially in modern power plants, reach efficiencies around 35% to 45%, depending on steam conditions and turbine design. The integration of gas and steam turbines in combined cycle power plants maximizes overall energy efficiency by utilizing waste heat from the gas turbine to generate steam for the steam turbine.

Fuel Types and Consumption

Gas turbines primarily use natural gas or liquid fuels such as diesel and jet fuel, offering rapid startup and high efficiency in power generation. Steam turbines rely on steam produced by burning coal, biomass, or utilizing nuclear energy, with fuel consumption influenced by the boiler's fuel source and steam cycle efficiency. Your choice between the two affects fuel flexibility, operational costs, and environmental impact based on the availability and type of fuel used.

Power Output and Performance

Gas turbines deliver high power output with rapid start-up times, making them ideal for peak load demands and flexible operations. Steam turbines typically achieve higher efficiency at a steady load, benefiting from the Rankine cycle in large-scale power plants. Performance of gas turbines improves with advanced materials and cooling techniques, while steam turbines excel in combined cycle setups for enhanced overall efficiency.

Environmental Impact and Emissions

Gas turbines produce lower carbon dioxide emissions per unit of electricity generated compared to steam turbines powered by coal or oil, due to higher combustion efficiency and cleaner fuel use such as natural gas. Steam turbines often rely on fossil fuels with higher particulate and sulfur dioxide emissions, contributing to acid rain and smog formation. You can reduce your environmental footprint by selecting gas turbine technology for cleaner, more efficient power generation with fewer harmful emissions.

Maintenance Requirements and Costs

Gas turbines demand frequent inspections and preventive maintenance due to high-temperature operation and complex combustion systems, leading to higher routine upkeep costs. Steam turbines, operating at lower temperatures and fewer moving parts, typically require less frequent maintenance, resulting in comparatively lower long-term service expenses. Your choice should weigh the immediate maintenance intensity of gas turbines against the steadier, more predictable costs associated with steam turbines.

Applications in Industry and Power Generation

Gas turbines are extensively used in aviation, natural gas processing, and peaking power plants due to their rapid start-up capabilities and high power-to-weight ratio. Steam turbines dominate large-scale power generation in thermal power plants, nuclear reactors, and cogeneration facilities because of their high efficiency in converting heat energy from steam into electricity. You can optimize power generation by selecting gas turbines for flexible, on-demand electricity and steam turbines for continuous, base-load energy production.

Advantages and Limitations

Gas turbines offer higher power-to-weight ratios and faster start-up times, making them ideal for power generation and aviation applications requiring quick responsiveness. Steam turbines provide higher efficiency at constant, large-scale power output, commonly used in power plants with fuel flexibility and lower operational noise. Limitations of gas turbines include lower efficiency at partial loads and sensitivity to fuel quality, whereas steam turbines require lengthy startup periods and complex water treatment systems.

Future Trends and Technological Innovations

Gas turbines are advancing with innovations in materials science, such as ceramic matrix composites, enhancing thermal efficiency and enabling higher operating temperatures. Steam turbines benefit from digital monitoring and predictive maintenance technologies, improving reliability and performance in power plants. Future trends include hybrid systems that integrate gas and steam turbines with renewable energy sources to achieve lower emissions and greater energy efficiency.

Gas Turbine vs Steam Turbine Infographic

libmatt.com

libmatt.com