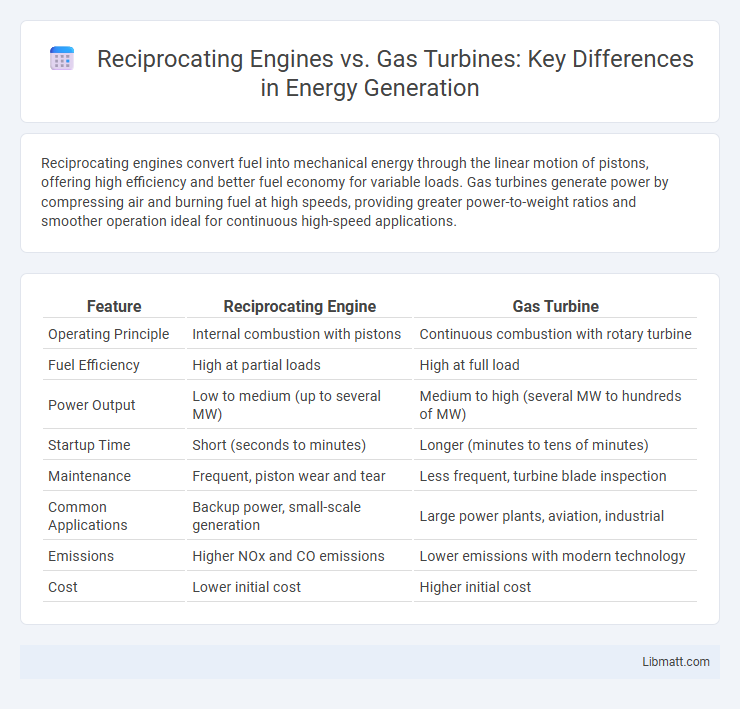

Reciprocating engines convert fuel into mechanical energy through the linear motion of pistons, offering high efficiency and better fuel economy for variable loads. Gas turbines generate power by compressing air and burning fuel at high speeds, providing greater power-to-weight ratios and smoother operation ideal for continuous high-speed applications.

Table of Comparison

| Feature | Reciprocating Engine | Gas Turbine |

|---|---|---|

| Operating Principle | Internal combustion with pistons | Continuous combustion with rotary turbine |

| Fuel Efficiency | High at partial loads | High at full load |

| Power Output | Low to medium (up to several MW) | Medium to high (several MW to hundreds of MW) |

| Startup Time | Short (seconds to minutes) | Longer (minutes to tens of minutes) |

| Maintenance | Frequent, piston wear and tear | Less frequent, turbine blade inspection |

| Common Applications | Backup power, small-scale generation | Large power plants, aviation, industrial |

| Emissions | Higher NOx and CO emissions | Lower emissions with modern technology |

| Cost | Lower initial cost | Higher initial cost |

Introduction to Reciprocating Engines and Gas Turbines

Reciprocating engines operate on the principle of converting linear piston motion into rotational motion, commonly used in automobiles and small machinery due to their high torque at low speeds and fuel efficiency. Gas turbines function by drawing in air, compressing it, mixing with fuel, and igniting the mixture to produce high-velocity exhaust gases that spin turbine blades, making them ideal for power generation and aviation applications because of their high power-to-weight ratio and continuous operation. Both engine types differ significantly in mechanical design, fuel consumption patterns, and typical applications, influencing their selection based on performance requirements and operational contexts.

Fundamental Working Principles

Reciprocating engines operate on the principle of converting chemical energy from fuel combustion into mechanical energy through the linear motion of pistons within cylinders. Gas turbines function by compressing air, mixing it with fuel, and igniting the mixture to produce high-velocity exhaust gases that spin turbine blades, generating rotational energy. The fundamental distinction lies in reciprocating engines using intermittent piston strokes versus gas turbines employing continuous combustion and rotational motion to produce power.

Key Components Comparison

Reciprocating engines consist primarily of pistons, cylinders, crankshafts, and valves that convert fuel combustion into mechanical motion through linear reciprocation. Gas turbines feature a compressor, combustion chamber, and turbine blades, where continuous combustion generates high-velocity gas flow to spin the turbine shaft for power output. The key distinction lies in the reciprocating engine's use of intermittent combustion with moving pistons versus the gas turbine's continuous combustion with rotating components.

Efficiency and Performance Metrics

Reciprocating engines typically achieve thermal efficiencies of 30-40%, excelling in part-load performance and fuel flexibility, making them ideal for applications requiring variable power output. Gas turbines offer higher power-to-weight ratios and can reach efficiencies above 40%, especially in combined cycle configurations, providing superior performance at continuous high-speed operation. Performance metrics favor reciprocating engines for low-speed, high-torque demands, while gas turbines dominate in applications prioritizing power density and consistent output.

Fuel Types and Consumption

Reciprocating engines primarily use fuels like gasoline, diesel, and natural gas, offering high efficiency at lower speeds and varied load conditions due to their ability to optimize fuel consumption. Gas turbines operate mainly on jet fuel or natural gas, delivering better fuel efficiency at constant high-speed operations but typically consuming more fuel at partial loads. Your choice between these engines should consider fuel availability and consumption patterns aligned with operational demands for optimal performance.

Maintenance Requirements and Costs

Reciprocating engines typically require more frequent maintenance due to their numerous moving parts, including regular oil changes, valve adjustments, and piston inspections, which can translate to higher operational costs over time. Gas turbines have fewer moving components and generally benefit from longer maintenance intervals but involve more specialized and costly inspections and part replacements, especially for turbine blades and combustors. Your choice between these engines should consider the trade-off between the routine, labor-intensive servicing of reciprocating engines and the high-cost, less frequent maintenance characteristic of gas turbines.

Environmental Impact and Emissions

Reciprocating engines generally produce higher levels of nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter compared to gas turbines, which operate at higher combustion temperatures and more complete fuel oxidation, resulting in lower emissions. Gas turbines benefit from advanced combustion technologies and can utilize cleaner fuels, reducing their overall environmental impact and carbon footprint. Your choice between the two should consider emissions regulations and sustainability goals to minimize environmental harm.

Applications Across Industries

Reciprocating engines power a wide range of industries, including automotive, marine, and small-scale power generation, due to their efficiency in variable load conditions and ease of maintenance. Gas turbines find extensive applications in aviation, power plants, and large-scale industrial operations where high power output and reliability are critical. Your choice between these engines depends on factors like load variability, power requirements, and operational environment specific to your industry.

Advantages and Limitations

Reciprocating engines offer high thermal efficiency and are well-suited for varying load conditions, making them ideal for small to medium power applications with easier maintenance and lower initial costs. Gas turbines provide higher power-to-weight ratios and better performance at continuous high-speed operations, benefiting large-scale power generation and aviation but suffer from lower efficiency at partial loads and higher fuel consumption. Limitations of reciprocating engines include increased vibration and noise, while gas turbines face issues with sensitivity to fuel quality and complex maintenance requirements.

Future Trends and Technological Innovations

Reciprocating engines are advancing with innovations in fuel efficiency and emissions reduction through hybridization and electrification, while gas turbines are evolving via additive manufacturing and advanced materials that enable higher operating temperatures and improved power-to-weight ratios. Future trends indicate a shift toward integrating renewable fuels such as hydrogen, enhancing digital twin technology for predictive maintenance in both engine types, and adopting variable geometry components to optimize performance across varying loads. The growing demand for sustainable aviation and power generation accelerates the development of low-emission reciprocating engines and high-efficiency gas turbines capable of operating on sustainable aviation fuels (SAFs) and biofuels.

Reciprocating Engine vs Gas Turbine Infographic

libmatt.com

libmatt.com