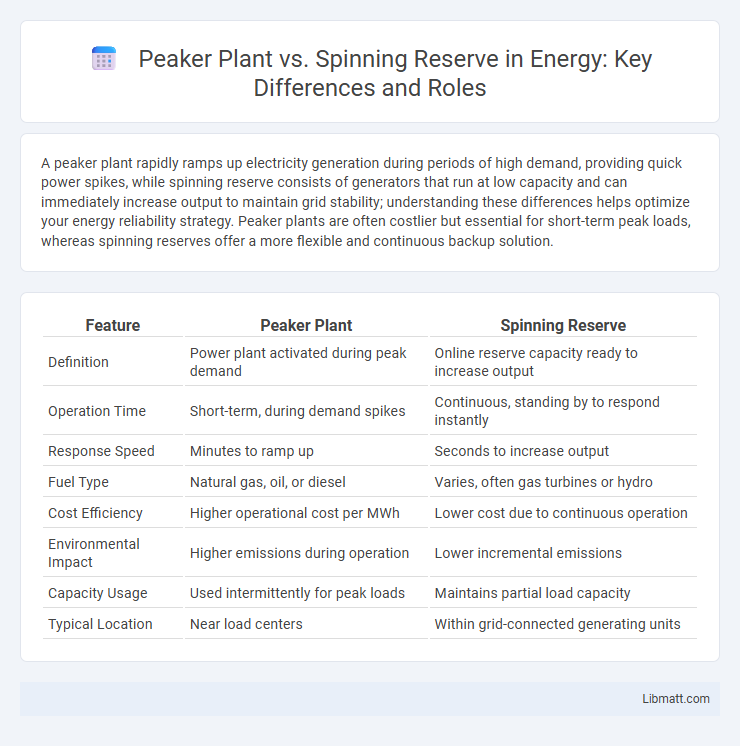

A peaker plant rapidly ramps up electricity generation during periods of high demand, providing quick power spikes, while spinning reserve consists of generators that run at low capacity and can immediately increase output to maintain grid stability; understanding these differences helps optimize your energy reliability strategy. Peaker plants are often costlier but essential for short-term peak loads, whereas spinning reserves offer a more flexible and continuous backup solution.

Table of Comparison

| Feature | Peaker Plant | Spinning Reserve |

|---|---|---|

| Definition | Power plant activated during peak demand | Online reserve capacity ready to increase output |

| Operation Time | Short-term, during demand spikes | Continuous, standing by to respond instantly |

| Response Speed | Minutes to ramp up | Seconds to increase output |

| Fuel Type | Natural gas, oil, or diesel | Varies, often gas turbines or hydro |

| Cost Efficiency | Higher operational cost per MWh | Lower cost due to continuous operation |

| Environmental Impact | Higher emissions during operation | Lower incremental emissions |

| Capacity Usage | Used intermittently for peak loads | Maintains partial load capacity |

| Typical Location | Near load centers | Within grid-connected generating units |

Introduction to Peaker Plants and Spinning Reserve

Peaker plants are specialized power stations designed to quickly generate electricity during peak demand periods, providing rapid-response energy to stabilize the grid. Spinning reserve refers to generation capacity from online, synchronized units that can ramp up output immediately to handle sudden supply disruptions or demand spikes. Your energy strategy benefits from understanding how peaker plants complement spinning reserves to maintain grid reliability and prevent outages.

Definitions: Peaker Plant vs. Spinning Reserve

A Peaker Plant is a power generation facility designed to operate during periods of high electricity demand, typically providing quick-start capacity to stabilize the grid. Spinning Reserve refers to the extra generating capacity that is online but not fully loaded, ready to immediately supply power if there is a sudden shortfall in electricity. Understanding the differences helps you optimize grid reliability by balancing fast-start peaking plants with the continuously available spinning reserves.

Role in Grid Stability

Peaker plants provide rapid power generation during peak demand periods, ensuring grid stability by quickly compensating for sudden energy shortfalls. Spinning reserves consist of online, unloaded generators that can instantly ramp up output, maintaining frequency and voltage stability. Both mechanisms are essential for balancing supply and demand fluctuations, preventing blackouts and maintaining reliable grid operation.

Operational Principles

Peaker plants operate by quickly ramping up electricity generation during peak demand periods, using fast-start turbines or engines to provide immediate power. Spinning reserves involve generating capacity already online but operating below maximum output, ready to increase power instantaneously to maintain grid stability. Your energy strategy benefits from understanding these operational principles to ensure reliability and efficiency during demand fluctuations.

Response Time Comparison

Peaker plants typically provide rapid response times, often ramping up electricity generation within 10 to 30 minutes to meet sudden demand spikes, whereas spinning reserves are online generating units that can respond within seconds to a few minutes by increasing output from their already synchronized operation. The key difference lies in availability; spinning reserves maintain continuous readiness and can deliver immediate power boost, while peaker plants require start-up time due to their offline status. Your power system's reliability depends heavily on the strategic balance between the swift activation of spinning reserves and the capacity flexibility of peaker plants.

Cost Differences

Peaker plants generally have higher operational costs than spinning reserves due to their reliance on fast-start, often less efficient gas turbines that incur higher fuel expenses. Spinning reserves, using already running generators synchronized to the grid, incur lower incremental costs as they maintain readiness without the need for full startup fuel consumption. Your cost optimization strategy should consider that peaker plants offer quick start capabilities at premium fuel costs, while spinning reserves provide a more economical solution for short-term backup power.

Environmental Impact

Peaker plants typically rely on fossil fuels, leading to higher greenhouse gas emissions and air pollution compared to spinning reserves, which are often generated by already-running power units and therefore do not require additional fuel combustion. Spinning reserves provide a cleaner backup by utilizing existing generation capacity without the need for startup emissions associated with peaker plants. The environmental impact of peaker plants is significant due to their intermittent use and reliance on less efficient engines, whereas spinning reserves optimize energy use and reduce overall emissions in grid management.

Technological Advancements

Peaker plants have evolved with advancements in fast-start gas turbines and energy storage systems, enabling rapid response to peak electricity demand. Spinning reserves rely increasingly on smart grid technologies and real-time monitoring to maintain grid stability and operational flexibility. Your energy management strategies benefit from integrating these technologies for enhanced reliability and cost efficiency in power supply.

Integration with Renewable Energy

Peaker plants provide rapid, on-demand electricity generation to balance fluctuations caused by intermittent renewable energy sources like solar and wind, ensuring grid reliability during peak demand periods. Spinning reserve consists of online but unloaded generation capacity that can quickly respond within seconds to sudden drops in renewable output, maintaining grid stability without the need for startup times. Your energy strategy benefits from combining peaker plants' flexibility with spinning reserves' immediate responsiveness, optimizing integration with expanding renewable energy capacity.

Future Trends in Grid Reserve Solutions

Peaker plants, traditionally used to meet peak electricity demand, are increasingly being complemented or replaced by enhanced spinning reserves leveraging battery energy storage systems (BESS) and demand response technologies. Future grid reserve solutions emphasize faster response times, higher flexibility, and integration with renewable energy sources to maintain grid stability and reliability. Advancements in grid-scale energy storage and smart grid management are key drivers for evolving spinning reserves, reducing reliance on carbon-intensive peaker plants.

Peaker plant vs Spinning reserve Infographic

libmatt.com

libmatt.com