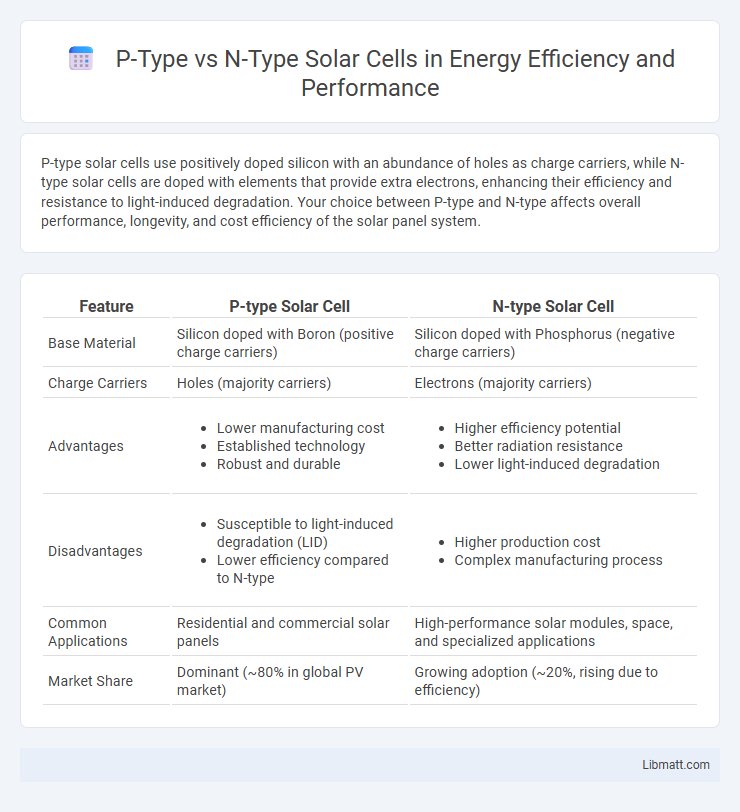

P-type solar cells use positively doped silicon with an abundance of holes as charge carriers, while N-type solar cells are doped with elements that provide extra electrons, enhancing their efficiency and resistance to light-induced degradation. Your choice between P-type and N-type affects overall performance, longevity, and cost efficiency of the solar panel system.

Table of Comparison

| Feature | P-type Solar Cell | N-type Solar Cell |

|---|---|---|

| Base Material | Silicon doped with Boron (positive charge carriers) | Silicon doped with Phosphorus (negative charge carriers) |

| Charge Carriers | Holes (majority carriers) | Electrons (majority carriers) |

| Advantages |

|

|

| Disadvantages |

|

|

| Common Applications | Residential and commercial solar panels | High-performance solar modules, space, and specialized applications |

| Market Share | Dominant (~80% in global PV market) | Growing adoption (~20%, rising due to efficiency) |

Introduction to P-type and N-type Solar Cells

P-type and N-type solar cells are distinguished by the type of semiconductor material used, where P-type cells utilize silicon doped with elements like boron creating positive charge carriers (holes), and N-type cells use silicon doped with phosphorus producing negative charge carriers (electrons). The junction between P-type and N-type materials forms the crucial p-n junction responsible for photovoltaic energy conversion. N-type solar cells generally exhibit higher efficiency and greater resistance to light-induced degradation compared to P-type cells, making them a preferred choice in advanced solar technologies.

Basic Principles of P-type vs N-type Silicon

P-type silicon is doped with boron atoms, creating an abundance of positive charge carriers or "holes," while N-type silicon is doped with phosphorus atoms, providing extra electrons as negative charge carriers. In solar cells, the p-n junction formed between P-type and N-type silicon layers facilitates the separation of electron-hole pairs generated by sunlight, driving electrical current. Understanding these doping mechanisms helps you optimize solar cell efficiency by leveraging the distinct electrical properties of P-type and N-type materials.

Manufacturing Process Differences

P-type solar cells are primarily made using boron-doped silicon wafers, where positive charge carriers (holes) dominate, while N-type cells use phosphorus-doped silicon wafers with electrons as the majority carriers. The manufacturing process for N-type cells often involves a more complex and costly diffusion step to introduce phosphorus atoms, but offers higher resistance to light-induced degradation compared to P-type cells. Your choice between P-type and N-type solar cells directly impacts the fabrication techniques, production costs, and long-term efficiency of your solar panels.

Electrical Properties and Performance

P-type solar cells feature a positive charge carrier majority due to the presence of holes, resulting in higher carrier mobility and typically better performance under lower irradiation conditions. N-type solar cells, with electrons as the majority carriers, exhibit superior resistance to common degradation mechanisms like light-induced degradation, enhancing long-term efficiency and stability. The electrical properties of N-type cells contribute to higher open-circuit voltage and improved overall energy conversion efficiency compared to P-type counterparts.

Efficiency Comparison: P-type vs N-type

N-type solar cells typically demonstrate higher efficiency compared to P-type cells due to their lower susceptibility to light-induced degradation and better tolerance to impurities. The inherent properties of N-type silicon, such as higher minority carrier lifetimes, result in improved energy conversion rates, especially under real-world operating conditions. If you're aiming to maximize your solar energy output, choosing N-type modules can offer a more efficient and durable solution.

Degradation and Longevity

P-type solar cells generally exhibit higher resistance to light-induced degradation (LID) due to their boron-doped silicon structure, resulting in better longevity under prolonged sunlight exposure. N-type solar cells, doped with phosphorus, show enhanced resilience against common degradation mechanisms such as potential-induced degradation (PID) and boron-oxygen complex formation, contributing to superior long-term performance. This inherent stability makes N-type cells particularly advantageous for applications requiring sustained efficiency and durability over decades.

Cost Analysis and Market Trends

P-type solar cells dominate the market due to their lower manufacturing costs and well-established production processes, driving economies of scale that result in competitive pricing. N-type solar cells, while more expensive to produce because of advanced materials like high-purity silicon and complex doping techniques, offer higher efficiency and better resistance to degradation, attracting growing investment in premium solar products. Market trends indicate a gradual shift towards N-type technology as demand for high-performance modules rises, with cost reductions expected as innovation and volume production increase.

Applications and Suitability

P-type solar cells, characterized by a positively doped silicon base, are widely used in residential and commercial rooftop installations due to their cost-effectiveness and proven reliability. N-type solar cells, with a negatively doped silicon base, offer higher efficiency and better resistance to light-induced degradation, making them suitable for high-performance applications like utility-scale solar farms and space technology. The choice between P-type and N-type solar cells depends on factors like budget, efficiency requirements, and environmental conditions, influencing their application in diverse solar energy projects.

Recent Innovations in Solar Cell Types

Recent innovations in P-type solar cells emphasize enhancing passivation layers and using selective emitters to boost efficiency and reduce recombination losses. N-type solar cells gain attention for their superior tolerance to impurities and radiation, employing advanced interdigitated back contact (IBC) designs and PERL (Passivated Emitter Rear Locally diffused) structures to achieve higher conversion efficiencies. Both P-type and N-type cells increasingly incorporate bifacial architectures and heterojunction with intrinsic thin layer (HIT) technology to maximize energy yield in diverse environmental conditions.

Future Prospects and Industry Outlook

P-type solar cells, traditionally dominating the market due to their cost-effectiveness and established manufacturing processes, face increasing competition from N-type solar cells, which offer higher efficiency and better resistance to degradation. The future prospects favor N-type technology as it enables improved energy yield and enhanced performance under various environmental conditions, driving significant interest from leading photovoltaic manufacturers. Your investment in emerging N-type solar technologies could capitalize on industry trends that prioritize longevity, efficiency, and scalability in next-generation solar solutions.

P-type vs N-type Solar Cell Infographic

libmatt.com

libmatt.com