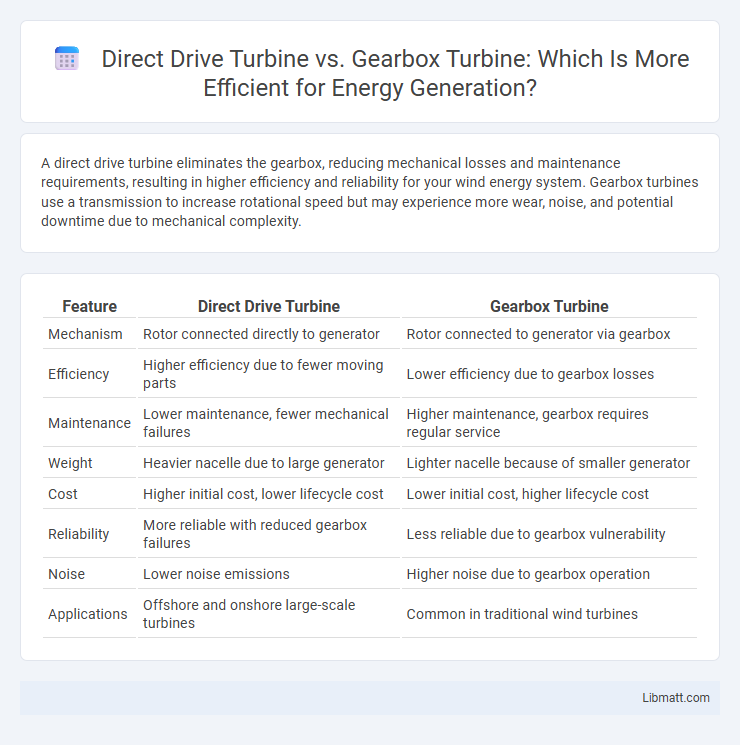

A direct drive turbine eliminates the gearbox, reducing mechanical losses and maintenance requirements, resulting in higher efficiency and reliability for your wind energy system. Gearbox turbines use a transmission to increase rotational speed but may experience more wear, noise, and potential downtime due to mechanical complexity.

Table of Comparison

| Feature | Direct Drive Turbine | Gearbox Turbine |

|---|---|---|

| Mechanism | Rotor connected directly to generator | Rotor connected to generator via gearbox |

| Efficiency | Higher efficiency due to fewer moving parts | Lower efficiency due to gearbox losses |

| Maintenance | Lower maintenance, fewer mechanical failures | Higher maintenance, gearbox requires regular service |

| Weight | Heavier nacelle due to large generator | Lighter nacelle because of smaller generator |

| Cost | Higher initial cost, lower lifecycle cost | Lower initial cost, higher lifecycle cost |

| Reliability | More reliable with reduced gearbox failures | Less reliable due to gearbox vulnerability |

| Noise | Lower noise emissions | Higher noise due to gearbox operation |

| Applications | Offshore and onshore large-scale turbines | Common in traditional wind turbines |

Introduction to Wind Turbine Technologies

Direct drive turbines utilize a permanent magnet generator directly connected to the rotor, eliminating the need for a gearbox and improving reliability and maintenance costs. Gearbox turbines incorporate a multi-stage gearbox to increase rotational speed, allowing the generator to operate efficiently at a higher RPM but introducing mechanical complexity and potential failure points. The choice between direct drive and gearbox turbines depends on factors such as turbine size, site conditions, and desired balance between performance and maintenance.

What is a Direct Drive Turbine?

A Direct Drive Turbine is a type of wind turbine that connects the rotor directly to the generator without using a gearbox, resulting in fewer moving parts and reduced mechanical losses. This design enhances efficiency and reliability by minimizing maintenance requirements and increasing the turbine's operational lifespan. Direct drive turbines are especially advantageous in offshore wind farms where durability and downtime reduction are critical.

What is a Gearbox Turbine?

A gearbox turbine incorporates a mechanical gearbox that increases the rotational speed from the low-speed turbine rotor to the high-speed generator, enhancing electricity production efficiency. This system enables the use of smaller, lighter generators by stepping up the turbine's slow rotational speed to match the generator's optimal operating speed. Your choice between a direct drive turbine and a gearbox turbine depends on factors like maintenance needs, cost, and turbine size.

Key Differences Between Direct Drive and Gearbox Turbines

Direct drive turbines eliminate the gearbox by connecting the rotor directly to the generator, resulting in fewer moving parts and reduced maintenance requirements. Gearbox turbines use a gearbox to increase the rotational speed of the low-speed rotor shaft to match the high-speed generator, allowing smaller, cost-effective generators but adding complexity and potential points of failure. You should choose direct drive turbines for improved reliability and lower maintenance, while gearbox turbines offer advantages in cost and weight efficiency for certain wind farm applications.

Efficiency Comparison: Direct Drive vs Gearbox

Direct drive turbines typically offer higher efficiency due to fewer mechanical components, reducing energy losses associated with gear meshing. Gearbox turbines, while initially less efficient, can achieve comparable performance with advanced gearbox designs but often require more maintenance. Your choice impacts long-term energy output and operational costs, making efficiency a critical factor in turbine selection.

Maintenance and Reliability Factors

Direct drive turbines eliminate the gearbox, reducing mechanical complexity and lowering maintenance requirements due to fewer moving parts prone to wear. Gearbox turbines involve regular inspections and lubricant changes to prevent gear failures, making them more maintenance-intensive and potentially less reliable over time. You benefit from increased reliability with direct drive turbines, as their simplified design minimizes downtime and maintenance costs.

Cost Analysis: Upfront and Long-Term Expenses

Direct drive turbines typically have higher upfront costs due to advanced permanent magnet generators but offer lower long-term expenses by minimizing maintenance and gearbox replacement. Gearbox turbines present lower initial investment but incur higher ongoing costs from gearbox wear, lubrication, and repairs. Your choice affects total cost of ownership, with direct drive models proving more economical over the turbine's lifespan.

Performance in Various Wind Conditions

Direct drive turbines offer superior performance in low to medium wind conditions due to fewer mechanical losses and enhanced efficiency through the elimination of gearbox friction. Gearbox turbines excel in high wind scenarios by allowing optimized rotor speeds and torque conversion, enabling greater energy capture from variable wind speeds. Overall, direct drive systems provide reliable power output with lower maintenance needs, while gearbox turbines maintain adaptability across a broader range of wind conditions.

Environmental Impact and Sustainability

Direct drive turbines reduce environmental impact by eliminating the need for lubricants and minimizing mechanical losses, leading to higher energy efficiency and decreased maintenance waste. Gearbox turbines rely on complex gears and lubricants, which can contribute to soil and water contamination if leaks occur, as well as increased resource consumption for manufacturing and disposal. Choosing a direct drive turbine enhances Your project's sustainability by promoting cleaner operation and reducing ecological footprint over its lifespan.

Choosing the Right Turbine: Factors to Consider

Choosing the right turbine requires evaluating efficiency, maintenance, and lifespan, where direct drive turbines offer lower mechanical losses and reduced maintenance due to fewer moving parts, while gearbox turbines provide cost advantages and higher torque conversion for varying wind speeds. Your decision should factor in site-specific wind conditions, operational reliability, and long-term performance goals to optimize energy output. Assessing initial investment versus total cost of ownership is essential when balancing the trade-offs between direct drive and gearbox turbine technologies.

Direct drive turbine vs Gearbox turbine Infographic

libmatt.com

libmatt.com