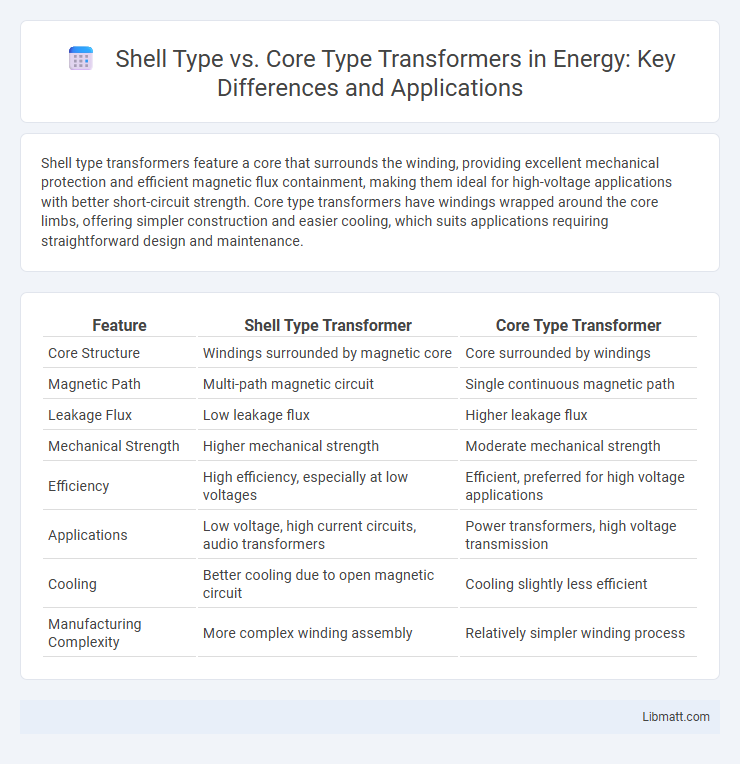

Shell type transformers feature a core that surrounds the winding, providing excellent mechanical protection and efficient magnetic flux containment, making them ideal for high-voltage applications with better short-circuit strength. Core type transformers have windings wrapped around the core limbs, offering simpler construction and easier cooling, which suits applications requiring straightforward design and maintenance.

Table of Comparison

| Feature | Shell Type Transformer | Core Type Transformer |

|---|---|---|

| Core Structure | Windings surrounded by magnetic core | Core surrounded by windings |

| Magnetic Path | Multi-path magnetic circuit | Single continuous magnetic path |

| Leakage Flux | Low leakage flux | Higher leakage flux |

| Mechanical Strength | Higher mechanical strength | Moderate mechanical strength |

| Efficiency | High efficiency, especially at low voltages | Efficient, preferred for high voltage applications |

| Applications | Low voltage, high current circuits, audio transformers | Power transformers, high voltage transmission |

| Cooling | Better cooling due to open magnetic circuit | Cooling slightly less efficient |

| Manufacturing Complexity | More complex winding assembly | Relatively simpler winding process |

Introduction to Transformers

Transformers are essential electrical devices designed to transfer electrical energy between circuits through electromagnetic induction, categorized mainly into shell type and core type based on their construction. Core type transformers have a rectangular core with windings placed on two sides, optimizing magnetic flux and mechanical strength, while shell type transformers encase the windings with magnetic core, providing better short circuit strength and reducing leakage flux. These structural differences impact efficiency, cooling methods, and typical applications in power distribution and industrial settings.

Overview of Shell Type and Core Type Transformers

Shell type transformers feature a core that surrounds the winding, providing enhanced mechanical protection and reduced leakage flux, leading to improved efficiency and voltage regulation. Core type transformers have windings placed around the laminated core limbs, offering simpler construction and ease of maintenance, commonly used in power distribution applications. Both types serve distinct roles based on design emphasis, with shell types favored for high-voltage or precision requirements and core types preferred for general power transmission.

Construction Differences: Shell Type vs Core Type

Shell type transformers feature a core that surrounds the winding, providing enhanced mechanical protection and reduced leakage reactance. Core type transformers have windings encircling a substantial portion of the core, resulting in simpler construction but higher flux leakage. Your choice between these types depends on factors like durability requirements and efficiency priorities in your electrical application.

Magnetic Flux Distribution in Each Type

In shell type transformers, the magnetic flux is concentrated within a closed magnetic path formed by the core surrounding the windings, resulting in efficient flux distribution and reduced leakage. Core type transformers exhibit magnetic flux flowing primarily within the core limbs, with the windings placed on opposite sides, which may cause higher flux leakage compared to shell types. The enclosed magnetic circuit in shell type transformers minimizes stray flux and enhances overall magnetic coupling between primary and secondary windings.

Efficiency Comparison: Shell Type vs Core Type

Shell type transformers generally offer higher efficiency compared to core type transformers due to their superior magnetic flux containment, which reduces core losses. The shell type's laminated core structure minimizes hysteresis and eddy current losses by providing better magnetic path control, resulting in lower energy dissipation. Core type transformers exhibit slightly lower efficiency as their simpler core design allows more magnetic leakage and higher core losses, especially at increased load conditions.

Applications of Shell Type Transformers

Shell type transformers are commonly used in applications requiring high efficiency and superior mechanical strength, such as in industrial machinery and power distribution systems. Their construction allows for better short-circuit protection and reduced leakage reactance, making them ideal for heavy-duty electrical loads and sensitive electronic equipment. If your application demands durability and reliable voltage regulation, choosing a shell type transformer ensures enhanced performance and longevity.

Applications of Core Type Transformers

Core type transformers are widely used in applications where efficient voltage regulation and low losses are critical, such as power distribution and transmission systems. They are commonly found in industrial plants, commercial buildings, and substations due to their ability to handle high voltage and current levels with enhanced magnetic flux control. Your choice of a core type transformer can improve electrical performance in energy-intensive environments, ensuring reliability and stability in power supply.

Advantages and Disadvantages of Shell Type

Shell type transformers feature a core that surrounds the windings, offering superior mechanical strength and better short-circuit resistance compared to core type transformers. Their design enables improved insulation and reduced magnetic flux leakage, resulting in enhanced efficiency and reduced noise levels. However, shell type transformers tend to be more complex and expensive to manufacture, with limited accessibility for maintenance and repairs.

Advantages and Disadvantages of Core Type

Core type transformers offer straightforward construction with easier winding and maintenance, making them cost-effective and reliable for various applications. Their design enables efficient cooling and lower magnetic losses, but they tend to be bulkier and less mechanically robust compared to shell type transformers. Your choice of core type transformers can benefit installations requiring simple design and easy adaptability, despite the trade-off in physical size and protection.

Key Factors for Selecting Transformer Types

Key factors for selecting transformer types include voltage levels, application requirements, and fault tolerance. Shell type transformers provide better mechanical strength and are suitable for high voltage and heavy-duty industrial use, while core type transformers offer simpler construction and are often preferred for distribution and lower voltage applications. Efficiency, cooling methods, and space constraints also influence the decision between shell type and core type transformers.

Shell Type vs Core Type Transformer Infographic

libmatt.com

libmatt.com