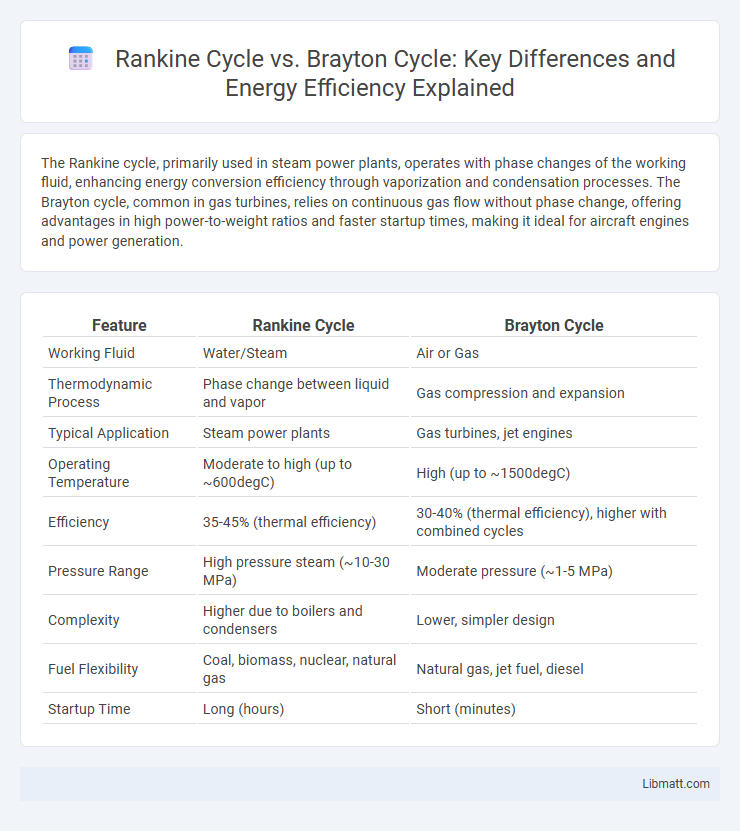

The Rankine cycle, primarily used in steam power plants, operates with phase changes of the working fluid, enhancing energy conversion efficiency through vaporization and condensation processes. The Brayton cycle, common in gas turbines, relies on continuous gas flow without phase change, offering advantages in high power-to-weight ratios and faster startup times, making it ideal for aircraft engines and power generation.

Table of Comparison

| Feature | Rankine Cycle | Brayton Cycle |

|---|---|---|

| Working Fluid | Water/Steam | Air or Gas |

| Thermodynamic Process | Phase change between liquid and vapor | Gas compression and expansion |

| Typical Application | Steam power plants | Gas turbines, jet engines |

| Operating Temperature | Moderate to high (up to ~600degC) | High (up to ~1500degC) |

| Efficiency | 35-45% (thermal efficiency) | 30-40% (thermal efficiency), higher with combined cycles |

| Pressure Range | High pressure steam (~10-30 MPa) | Moderate pressure (~1-5 MPa) |

| Complexity | Higher due to boilers and condensers | Lower, simpler design |

| Fuel Flexibility | Coal, biomass, nuclear, natural gas | Natural gas, jet fuel, diesel |

| Startup Time | Long (hours) | Short (minutes) |

Introduction to Rankine and Brayton Cycles

The Rankine cycle, commonly used in steam power plants, converts heat into mechanical work through the phase change of water into steam, driving turbines for electricity generation. The Brayton cycle, primarily applied in gas turbine engines, operates with continuous combustion of air-fuel mixtures to produce high-temperature, high-pressure gas expanding through turbines. Both cycles form the foundation of thermal power generation, with Rankine favoring steam cycles and Brayton emphasizing gas turbine applications.

Basic Working Principles

The Rankine cycle operates on the principle of phase change, using a liquid-vapor phase transition in a closed loop to convert heat into mechanical work, typically involving a boiler, turbine, condenser, and pump. The Brayton cycle functions on continuous combustion of a gas, where compressed air is heated at constant pressure and expanded through a turbine, typical in gas turbine engines. Both cycles aim to convert thermal energy into mechanical work but differ fundamentally--Rankine uses steam and phase change, while Brayton uses continuous gas flow and pressure changes.

Key Components Comparison

The Rankine cycle primarily consists of a boiler, turbine, condenser, and pump, where water is the working fluid undergoing phase changes to convert heat into mechanical work. The Brayton cycle features a compressor, combustion chamber, turbine, and exhaust system, utilizing air or gas as the working fluid in a continuous gas flow process. Understanding the key components helps you optimize thermal efficiency and select the appropriate cycle for power generation applications.

Thermodynamic Processes

The Rankine cycle primarily involves phase changes, utilizing liquid water and steam to convert heat into mechanical work through evaporation and condensation processes. The Brayton cycle operates entirely with gases, typically air or combustion products, relying on isentropic compression and expansion without phase change. Your choice between these cycles depends on application needs for efficiency and the working fluid's thermodynamic behavior.

Fuel Sources and Efficiency

The Rankine cycle primarily uses water or steam as the working fluid, making it ideal for fuel sources like coal, biomass, nuclear, and geothermal energy, with thermal efficiencies typically ranging from 30% to 45%. The Brayton cycle operates mainly with air and is favored in gas turbines fueled by natural gas, jet fuel, or other hydrocarbons, achieving efficiency levels between 35% and 40%, with higher efficiencies possible through combined cycle configurations. Your choice between these cycles should depend on the available fuel source and desired efficiency, as Rankine cycles excel in steady, high-heat applications, while Brayton cycles fit dynamic, high-power scenarios.

Applications in Power Generation

The Rankine cycle is predominantly used in steam power plants for electricity generation by converting heat from fuel combustion or nuclear reactions into mechanical work through steam turbines. The Brayton cycle powers gas turbine plants, commonly employed in aviation and combined-cycle power plants for efficient electricity production. Both cycles play crucial roles in modern power generation, with Rankine cycles favoring large-scale, steady-state operations and Brayton cycles excelling in high-speed, flexible applications.

Environmental Impact

The Rankine cycle, primarily used in steam power plants, typically relies on water and steam, producing lower greenhouse gas emissions when paired with renewable energy sources or carbon capture technologies. The Brayton cycle, common in gas turbines, often burns natural gas or jet fuel, leading to higher CO2 and NOx emissions, which contribute significantly to air pollution and climate change. Efforts to improve the environmental impact of both cycles focus on increasing efficiency and integrating cleaner fuels, such as hydrogen or biofuels, to reduce carbon footprints.

Advantages and Limitations

The Rankine cycle offers high efficiency in converting heat from steam into mechanical work, making it ideal for power plants using water as a working fluid. Its main limitation is the slow startup time and reduced efficiency at partial loads compared to the Brayton cycle, which excels in faster startup and better adaptability to varying loads due to its use of gas turbines. Your choice depends on operational needs: Rankine cycles suit steady, large-scale power generation, while Brayton cycles provide flexibility and quicker response for variable power demands.

Recent Innovations and Improvements

Recent innovations in the Rankine cycle include supercritical and ultra-supercritical steam conditions that enhance thermal efficiency and reduce emissions in power plants. Advances in Brayton cycle technology focus on incorporating intercooling, reheating, and combined cycle configurations with gas turbines to maximize energy output and fuel utilization. Your choice between these cycles should consider the latest improvements in materials and system integration that drive higher performance and environmental sustainability.

Future Trends in Power Cycles

Future trends in power cycles highlight the shift towards hybrid systems combining Rankine and Brayton cycles to maximize efficiency and reduce emissions. Advanced materials and supercritical CO2 fluids enable both cycles to operate at higher temperatures and pressures, enhancing performance. Your energy projects can benefit from integrating these innovations to meet evolving environmental regulations and sustainability goals.

Rankine cycle vs Brayton cycle Infographic

libmatt.com

libmatt.com