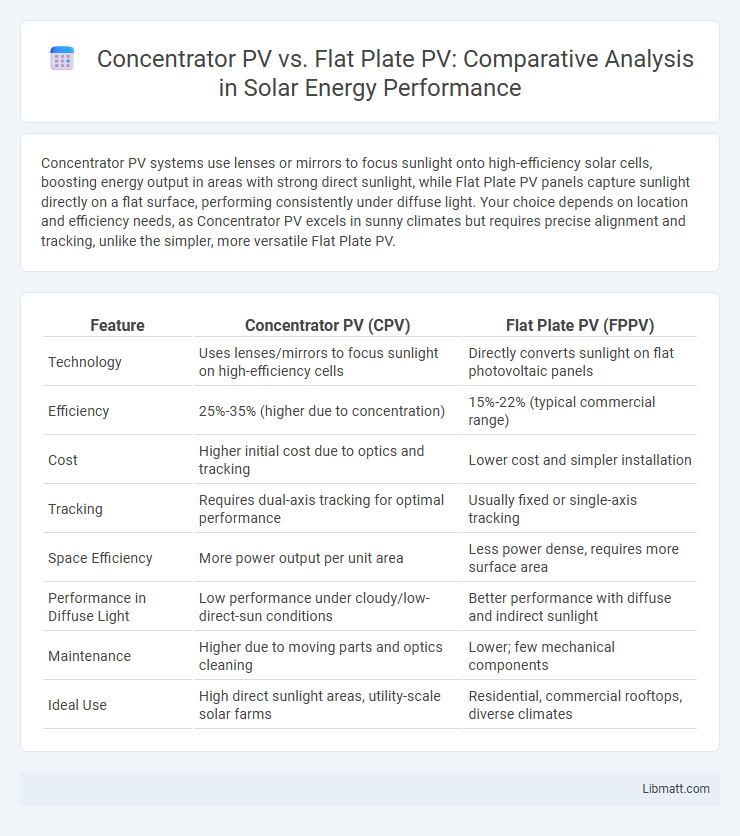

Concentrator PV systems use lenses or mirrors to focus sunlight onto high-efficiency solar cells, boosting energy output in areas with strong direct sunlight, while Flat Plate PV panels capture sunlight directly on a flat surface, performing consistently under diffuse light. Your choice depends on location and efficiency needs, as Concentrator PV excels in sunny climates but requires precise alignment and tracking, unlike the simpler, more versatile Flat Plate PV.

Table of Comparison

| Feature | Concentrator PV (CPV) | Flat Plate PV (FPPV) |

|---|---|---|

| Technology | Uses lenses/mirrors to focus sunlight on high-efficiency cells | Directly converts sunlight on flat photovoltaic panels |

| Efficiency | 25%-35% (higher due to concentration) | 15%-22% (typical commercial range) |

| Cost | Higher initial cost due to optics and tracking | Lower cost and simpler installation |

| Tracking | Requires dual-axis tracking for optimal performance | Usually fixed or single-axis tracking |

| Space Efficiency | More power output per unit area | Less power dense, requires more surface area |

| Performance in Diffuse Light | Low performance under cloudy/low-direct-sun conditions | Better performance with diffuse and indirect sunlight |

| Maintenance | Higher due to moving parts and optics cleaning | Lower; few mechanical components |

| Ideal Use | High direct sunlight areas, utility-scale solar farms | Residential, commercial rooftops, diverse climates |

Introduction to Concentrator PV and Flat Plate PV

Concentrator PV systems use lenses or mirrors to focus sunlight onto high-efficiency solar cells, significantly increasing energy output in high-direct-sunlight environments. Flat Plate PV panels consist of a flat, stationary surface with semiconductor materials that convert sunlight directly into electricity, offering reliable performance under diffuse and varying light conditions. Both technologies serve different applications based on geographic location, efficiency requirements, and installation costs.

How Concentrator PV Systems Work

Concentrator PV systems use lenses or mirrors to focus sunlight onto high-efficiency solar cells, intensifying the solar energy received for greater electricity generation. Unlike flat plate PV modules, which directly convert diffuse sunlight over a broad surface, concentrator PV requires precise tracking mechanisms to maintain optimal alignment with the sun's rays. Your ability to harness more power in limited space makes concentrator PV ideal for areas with high direct sunlight and stringent efficiency demands.

Principles of Flat Plate PV Panels

Flat plate PV panels operate on the principle of converting sunlight directly into electricity using photovoltaic cells embedded in a flat, rectangular surface. These panels absorb solar radiation over their entire surface area without concentrating sunlight, making them effective for capturing diffuse light in various conditions. Your energy system benefits from the simplicity and durability of flat plate PV panels, which offer steady performance without the need for tracking systems.

Efficiency Comparison: Concentrator vs Flat Plate

Concentrator PV systems achieve higher efficiency by using lenses or mirrors to focus sunlight onto high-efficiency solar cells, often reaching conversion rates above 30%. In contrast, flat plate PV panels typically have lower efficiencies, averaging around 15-20%, due to direct exposure to diffuse and direct sunlight without concentration. The enhanced efficiency of concentrator PV makes them ideal for high solar irradiance regions, though they require precise solar tracking and cooling systems.

Land and Space Requirements

Concentrator PV systems require significantly less land area than flat plate PV systems due to their use of lenses or mirrors to focus sunlight onto smaller, high-efficiency solar cells, making them ideal for limited space applications. Flat plate PV panels occupy more surface area as they capture diffuse sunlight directly without concentration, necessitating more extensive installation sites for equivalent power output. The space efficiency of concentrator PV is advantageous in urban and constrained environments where maximizing energy generation per square meter is critical.

Performance in Different Climates

Concentrator PV systems deliver higher efficiency in regions with abundant direct sunlight, such as arid and desert climates, due to their ability to focus sunlight onto smaller, high-efficiency cells. Flat plate PV panels perform better in diffuse light conditions commonly found in cloudy or partially shaded environments, maintaining relatively steady energy output across varied weather. Climate factors like temperature and irradiance intensity significantly affect the comparative performance, with concentrator PV systems being less effective in cooler or overcast areas where diffuse radiation dominates.

Cost Analysis and Investment Considerations

Concentrator PV systems typically require higher initial investments due to the need for precise tracking mechanisms and specialized optics, whereas flat plate PV panels offer lower upfront costs and simpler installations. Maintenance expenses for concentrator PV tend to be elevated, driven by complex components, but they can achieve higher energy yields per unit area, potentially enhancing return on investment in high direct sunlight regions. Investment considerations should balance the increased capital and operational costs of concentrator systems against their efficiency advantages, particularly for large-scale projects in suitable climates.

Maintenance and Lifespan Differences

Concentrator PV systems require more frequent maintenance due to their complex tracking mechanisms and cooling needs, while flat plate PV panels offer simpler upkeep with fewer moving parts. The lifespan of flat plate PV modules often exceeds 25 years, benefiting from their robust design, whereas concentrator PV units may experience reduced longevity because of higher thermal and mechanical stress. You should consider maintenance capabilities and expected durability when choosing between these two photovoltaic technologies.

Scalability and Application Scenarios

Concentrator PV systems offer high scalability due to their ability to focus sunlight onto smaller, highly efficient solar cells, making them ideal for large-scale solar farms in regions with intense direct sunlight. Flat plate PV panels provide versatile scalability from small residential rooftops to utility-scale installations, performing consistently across various climates and diffuse light conditions. Applications for concentrator PV are typically utility-scale projects where land and high DNI (Direct Normal Irradiance) are available, while flat plate PV suits diverse environments including urban, residential, and off-grid systems.

Future Trends in PV Technology

Concentrator PV systems, leveraging advanced optics and multi-junction solar cells, are expected to achieve higher efficiency gains compared to traditional Flat Plate PV, which rely on semiconductor-based photovoltaic layers. Research in Concentrator PV focuses on reducing costs of concentrator optics and improving thermal management, making them suitable for utility-scale applications with intense solar exposure. Your choice in future PV technology should consider the rapid progress in Concentrator PV efficiency and the widespread adoption of Flat Plate PV due to lower initial costs and ease of installation.

Concentrator PV vs Flat Plate PV Infographic

libmatt.com

libmatt.com