Soft start devices gradually increase voltage to minimize mechanical stress on motors during startup, improving equipment longevity. Variable Frequency Drives (VFDs) control motor speed and torque by adjusting frequency and voltage, offering more precise energy savings and process control for Your applications.

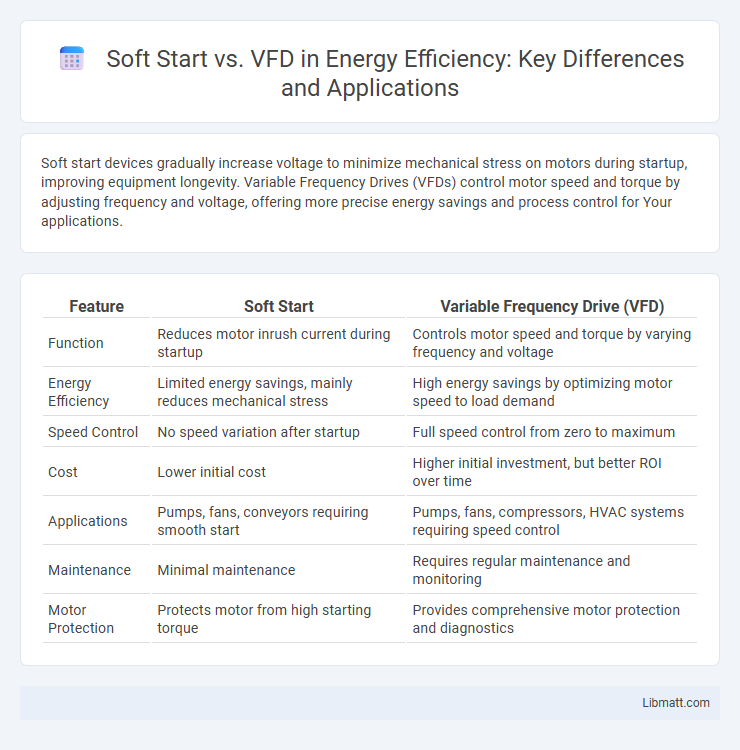

Table of Comparison

| Feature | Soft Start | Variable Frequency Drive (VFD) |

|---|---|---|

| Function | Reduces motor inrush current during startup | Controls motor speed and torque by varying frequency and voltage |

| Energy Efficiency | Limited energy savings, mainly reduces mechanical stress | High energy savings by optimizing motor speed to load demand |

| Speed Control | No speed variation after startup | Full speed control from zero to maximum |

| Cost | Lower initial cost | Higher initial investment, but better ROI over time |

| Applications | Pumps, fans, conveyors requiring smooth start | Pumps, fans, compressors, HVAC systems requiring speed control |

| Maintenance | Minimal maintenance | Requires regular maintenance and monitoring |

| Motor Protection | Protects motor from high starting torque | Provides comprehensive motor protection and diagnostics |

Introduction to Motor Starting Methods

Soft start and variable frequency drive (VFD) are two primary motor starting methods used to control the acceleration and reduce mechanical stress in electric motors. Soft start gradually ramps up voltage to the motor, minimizing inrush current and torque during startup, while VFD adjusts both voltage and frequency to provide precise speed control and enhanced energy efficiency throughout operation. Selecting the appropriate motor starting method depends on application requirements such as load characteristics, energy savings, and process control precision.

What is a Soft Starter?

A Soft Starter is an electronic device used to gradually ramp up the voltage supply to an electric motor, reducing inrush current and mechanical stress during startup. It ensures smoother acceleration, minimizes electrical disturbances, and extends the lifespan of motor components by avoiding sudden torque spikes. Soft Starters are ideal for applications requiring controlled startup without speed variation during operation.

What is a Variable Frequency Drive (VFD)?

A Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of an electric motor by varying the frequency and voltage of its power supply. Unlike soft starters that gradually ramp up voltage to reduce inrush current, VFDs offer precise motor speed control for enhanced energy efficiency and process optimization. VFDs are widely used in HVAC systems, conveyor belts, and pump applications to provide smooth operation and significant energy savings.

Key Differences Between Soft Starters and VFDs

Soft Starters and Variable Frequency Drives (VFDs) differ primarily in their control and efficiency capabilities; Soft Starters regulate motor voltage to reduce inrush current during startup, while VFDs provide comprehensive speed control by varying voltage and frequency. Soft Starters are ideal for applications requiring simple start and stop control with reduced mechanical stress, whereas VFDs enhance energy efficiency and performance by allowing precise motor speed adjustments during operation. Your choice depends on whether you need basic motor protection or advanced speed control and energy savings.

Performance and Control Capabilities

Soft start devices provide limited performance by gradually ramping up motor voltage to reduce inrush current, resulting in basic control over start-up torque and current. Variable Frequency Drives (VFDs) offer superior performance by precisely controlling motor speed and torque through adjustable frequency and voltage, enabling optimized process control and energy savings. Enhanced control capabilities of VFDs include adjustable acceleration/deceleration profiles, dynamic speed regulation, and integration with advanced automation systems for improved operational efficiency.

Energy Efficiency Comparison

Soft start devices reduce inrush current during motor startup but maintain full motor speed and load, resulting in minimal energy savings. Variable Frequency Drives (VFDs) optimize motor speed and torque throughout operation, leading to significant energy efficiency by matching power use to demand. Your choice of VFD can lower electricity costs substantially compared to soft start methods, especially in variable load applications.

Application Scenarios: When to Use Soft Start vs VFD

Soft start devices are ideal for applications requiring simple, cost-effective motor startup with reduced inrush current, such as conveyor systems and pumps that need smooth acceleration without variable speed control. Variable Frequency Drives (VFDs) excel in scenarios demanding precise speed regulation, energy efficiency, and dynamic control, including HVAC systems, variable torque applications, and industrial machinery with frequent speed adjustments. Selecting between soft start and VFD depends on load characteristics, control complexity, and energy-saving goals.

Cost Considerations and ROI

Soft start systems generally have lower initial costs compared to variable frequency drives (VFDs), making them more budget-friendly for simple motor startups. However, VFDs offer greater energy savings by precisely controlling motor speed, leading to a faster return on investment through reduced electricity bills and extended equipment life. For your facility, choosing a VFD can maximize long-term cost efficiency despite the higher upfront investment.

Installation and Maintenance Requirements

Soft start devices require simpler installation with fewer wiring connections and minimal configuration, making them ideal for straightforward motor control applications. Variable Frequency Drives (VFDs) involve more complex installation, including additional cooling and grounding considerations, as well as advanced programming for speed control. Maintenance for soft starters is generally lower due to fewer electronic components, whereas VFDs demand regular monitoring of cooling systems, capacitors, and firmware updates to ensure optimal performance.

Conclusion: Choosing the Right Solution for Your Needs

Selecting between a Soft Start and a Variable Frequency Drive (VFD) depends on specific application requirements such as torque control, energy efficiency, and system complexity. Soft Starts are ideal for reducing inrush current and mechanical stress during motor startup, offering a cost-effective and simple solution. VFDs provide precise speed control, improved energy savings, and enhanced process automation, making them suitable for applications demanding variable speed and load adaptability.

Soft Start vs VFD Infographic

libmatt.com

libmatt.com