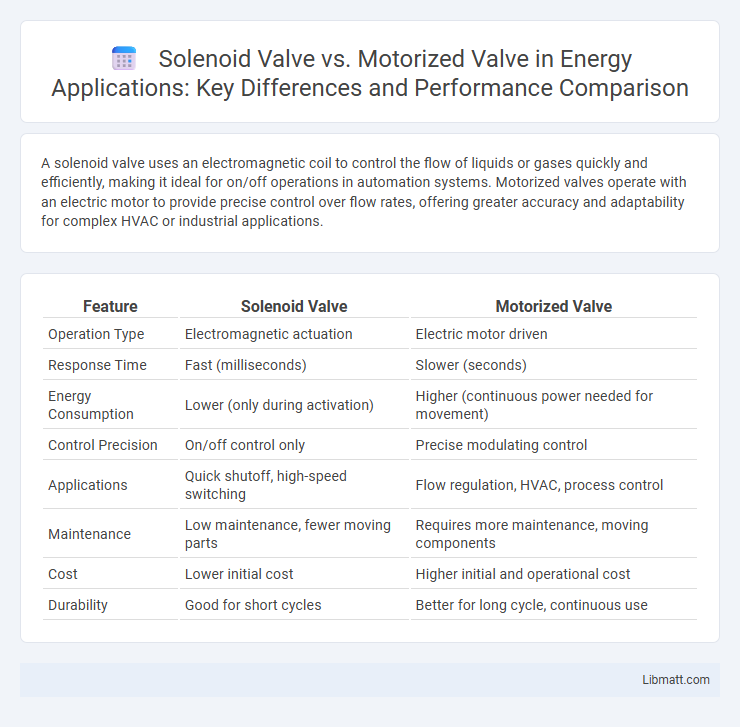

A solenoid valve uses an electromagnetic coil to control the flow of liquids or gases quickly and efficiently, making it ideal for on/off operations in automation systems. Motorized valves operate with an electric motor to provide precise control over flow rates, offering greater accuracy and adaptability for complex HVAC or industrial applications.

Table of Comparison

| Feature | Solenoid Valve | Motorized Valve |

|---|---|---|

| Operation Type | Electromagnetic actuation | Electric motor driven |

| Response Time | Fast (milliseconds) | Slower (seconds) |

| Energy Consumption | Lower (only during activation) | Higher (continuous power needed for movement) |

| Control Precision | On/off control only | Precise modulating control |

| Applications | Quick shutoff, high-speed switching | Flow regulation, HVAC, process control |

| Maintenance | Low maintenance, fewer moving parts | Requires more maintenance, moving components |

| Cost | Lower initial cost | Higher initial and operational cost |

| Durability | Good for short cycles | Better for long cycle, continuous use |

Introduction to Solenoid and Motorized Valves

Solenoid valves operate using electromagnetic force to control fluid flow quickly and efficiently, making them ideal for automation in HVAC and irrigation systems. Motorized valves use electric motors to adjust valve position precisely, offering better control over flow rates in applications like water treatment and industrial processes. Understanding your system's requirements helps determine whether the fast response of solenoid valves or the precise modulation of motorized valves is best suited for your needs.

Working Principle of Solenoid Valves

Solenoid valves operate by using an electromagnetic solenoid coil to control the flow of fluid or gas through a valve. When energized, the coil creates a magnetic field that moves a plunger or armature, opening or closing the valve with rapid response times. Understanding the working principle of solenoid valves helps you select the appropriate valve type for precise and efficient fluid control in various applications.

Working Principle of Motorized Valves

Motorized valves operate using an electric motor to control the valve position by converting electrical energy into mechanical torque, enabling precise modulation of fluid flow. Unlike solenoid valves that use electromagnetic force for quick open/close actions, motorized valves provide smooth, gradual control suitable for applications requiring accurate flow regulation. Your system benefits from motorized valves when precise control over flow rates or pressure is essential for optimal performance and efficiency.

Key Differences Between Solenoid and Motorized Valves

Solenoid valves use an electromagnetic solenoid to control the flow of fluid, offering fast response times and simple on/off operation, making them ideal for low-pressure systems. Motorized valves employ an electric motor to rotate or linear move the valve mechanism, providing precise flow control and suitability for high-pressure, larger diameter, or more complex applications. Key differences include actuation method, control precision, pressure handling capability, and application scope, with solenoid valves favored for quick, binary control and motorized valves used for modulated, variable flow regulation.

Advantages of Solenoid Valves

Solenoid valves offer rapid response times and precise control, making them ideal for applications requiring quick on/off operation. Their compact size and simple design result in easier installation and lower maintenance costs compared to motorized valves. You benefit from reliable performance in systems where minimal power consumption and fast actuation are critical.

Advantages of Motorized Valves

Motorized valves offer precise control over fluid flow with adjustable position settings, allowing for fine-tuned regulation in complex systems. Their ability to operate quietly and handle a wide range of pressures and temperatures makes them suitable for diverse industrial applications. You benefit from enhanced energy efficiency and longer service life compared to solenoid valves, reducing maintenance costs and downtime.

Common Applications: Solenoid vs Motorized Valves

Solenoid valves are commonly used in applications requiring fast, precise control of fluid or gas flow, such as in HVAC systems, irrigation, and pneumatic controls. Motorized valves are preferred in systems demanding accurate flow regulation over a wider range, including water treatment plants, industrial automation, and heating systems. Both types offer reliable flow control but differ in response time and suitability for pressure and flow variations.

Selection Criteria: Solenoid or Motorized Valve?

Solenoid valves are ideal for applications requiring rapid, on/off control with low power consumption and compact design, while motorized valves excel in precise flow regulation, handling higher pressures and larger pipe sizes. Selection depends on factors such as flow control accuracy, system pressure, response time, power availability, and maintenance requirements. Understanding the operational environment and specific application needs is crucial in choosing between solenoid and motorized valves to ensure optimal performance and reliability.

Maintenance and Reliability Comparison

Solenoid valves require less frequent maintenance due to their simple electromagnetic operation, but their faster wear on coils can reduce long-term reliability in high-cycle applications. Motorized valves, with their robust mechanical actuators and precise control, typically offer higher durability and easier maintenance through modular components replacement. Regular inspection of solenoid coil integrity and motorized valve gear lubrication ensures optimal performance and minimizes downtime.

Cost Analysis and Efficiency

Solenoid valves typically offer lower initial costs and faster response times, making them cost-effective for applications requiring frequent on-off cycles under low to medium pressure. Motorized valves, while having higher upfront investment, provide superior energy efficiency and precise flow control in high-pressure or large-volume systems, leading to long-term operational savings. Evaluating total cost of ownership must consider maintenance expenses, application-specific requirements, and energy consumption profiles to optimize valve selection.

Solenoid valve vs Motorized valve Infographic

libmatt.com

libmatt.com