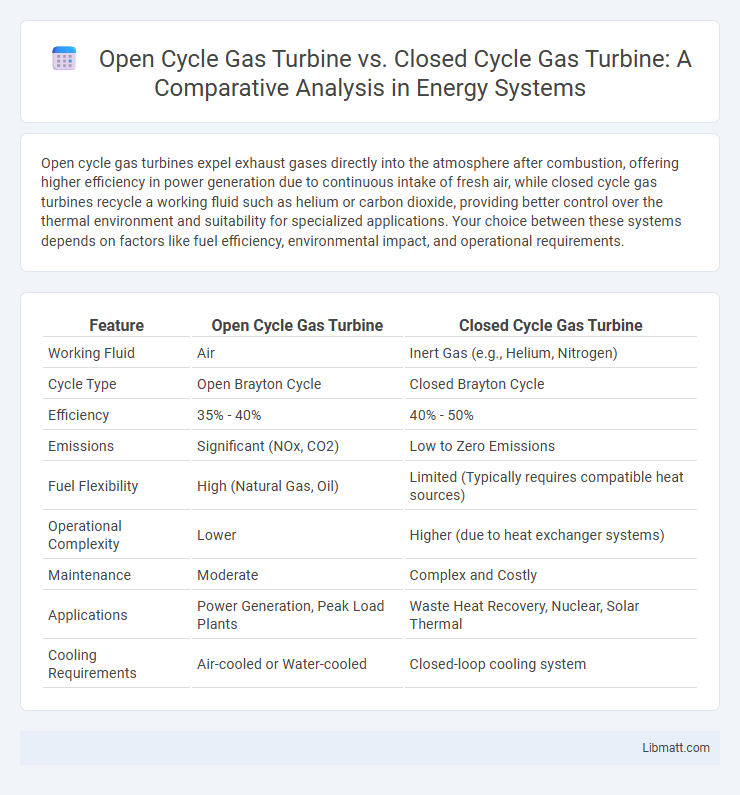

Open cycle gas turbines expel exhaust gases directly into the atmosphere after combustion, offering higher efficiency in power generation due to continuous intake of fresh air, while closed cycle gas turbines recycle a working fluid such as helium or carbon dioxide, providing better control over the thermal environment and suitability for specialized applications. Your choice between these systems depends on factors like fuel efficiency, environmental impact, and operational requirements.

Table of Comparison

| Feature | Open Cycle Gas Turbine | Closed Cycle Gas Turbine |

|---|---|---|

| Working Fluid | Air | Inert Gas (e.g., Helium, Nitrogen) |

| Cycle Type | Open Brayton Cycle | Closed Brayton Cycle |

| Efficiency | 35% - 40% | 40% - 50% |

| Emissions | Significant (NOx, CO2) | Low to Zero Emissions |

| Fuel Flexibility | High (Natural Gas, Oil) | Limited (Typically requires compatible heat sources) |

| Operational Complexity | Lower | Higher (due to heat exchanger systems) |

| Maintenance | Moderate | Complex and Costly |

| Applications | Power Generation, Peak Load Plants | Waste Heat Recovery, Nuclear, Solar Thermal |

| Cooling Requirements | Air-cooled or Water-cooled | Closed-loop cooling system |

Introduction to Gas Turbine Cycles

Open Cycle Gas Turbines operate by drawing ambient air, compressing it, mixing with fuel for combustion, and exhausting hot gases directly to the atmosphere, making them widely used in power generation and aviation for their simplicity and quick start-up. Closed Cycle Gas Turbines reuse the working fluid, typically helium or air, within a sealed system where heat is added externally, enhancing thermal efficiency and reducing emissions in specialized applications like space power plants and concentrated solar power systems. Understanding the fundamental differences in air intake, heat addition, and exhaust processes is crucial for optimizing performance according to operational requirements.

Overview of Open Cycle Gas Turbine

Open Cycle Gas Turbines (OCGT) operate by drawing ambient air into the compressor, mixing it with fuel, and combusting the mixture to produce high-temperature, high-pressure gases that drive the turbine. This type of gas turbine is widely used in power generation and aviation due to its simple design, quick start-up times, and lower initial costs. However, OCGTs have lower thermal efficiency compared to Closed Cycle Gas Turbines because exhaust gases are released directly into the atmosphere without energy recovery.

Overview of Closed Cycle Gas Turbine

Closed cycle gas turbines operate using a sealed working fluid, typically helium or supercritical CO2, which circulates within a closed loop to transfer heat from an external source to the turbine. This design enhances thermal efficiency by maintaining optimal gas properties and allowing the use of various heat sources such as nuclear, solar, or waste heat. Compared to open cycle gas turbines, closed cycle systems offer lower emissions, higher efficiency at smaller scales, and improved operational flexibility due to reduced gas contamination and controlled working fluid conditions.

Key Differences Between Open and Closed Cycle Systems

Open cycle gas turbines expel exhaust gases directly into the atmosphere after combustion, resulting in lower thermal efficiency and increased pollutant emissions. Closed cycle gas turbines recirculate a working fluid, such as helium or air, through a heat exchanger, enabling higher efficiency and reduced emissions by isolating the combustion process. The choice between systems hinges on application needs, with open cycles favored for simplicity and cost, while closed cycles offer enhanced efficiency and environmental benefits in specialized settings.

Efficiency Comparison: Open vs Closed Cycle

Open cycle gas turbines typically exhibit lower thermal efficiency, ranging between 30% to 40%, due to direct exposure to ambient conditions and energy losses in exhaust gases. Closed cycle gas turbines achieve higher efficiency, often exceeding 45%, by utilizing a working fluid in a sealed system that enables better temperature control and reduced energy waste. The closed cycle design allows for waste heat recovery and integration with heat exchangers, significantly improving overall efficiency compared to open cycle systems.

Operational and Maintenance Requirements

Open cycle gas turbines require regular inspection of combustion chambers, turbine blades, and air filters due to exposure to ambient air and combustion gases, increasing maintenance frequency. Closed cycle gas turbines operate with a sealed working fluid, resulting in reduced contamination and wear, which lowers maintenance needs and extends operational life. Operationally, open cycle turbines demand continuous fuel quality monitoring and environmental control, while closed cycle systems benefit from more stable operating conditions and simplified maintenance schedules.

Environmental Impact and Emissions

Open cycle gas turbines emit higher levels of nitrogen oxides (NOx) and carbon dioxide (CO2) due to direct combustion of fuel with atmospheric air, leading to increased greenhouse gas emissions and air pollution. Closed cycle gas turbines operate using a working fluid, such as helium or air, in a sealed system which significantly reduces direct emissions and allows for better integration with renewable heat sources, minimizing environmental footprint. The closed cycle design enhances efficiency and lowers pollutant release, making it a more sustainable option for power generation with reduced impact on climate change and local air quality.

Applications and Industry Usage

Open cycle gas turbines are widely used in power generation, aviation, and marine propulsion due to their ability to handle large airflows and provide quick start-up times, making them ideal for peak load electricity supply and jet engines. Closed cycle gas turbines find applications in nuclear power plants, concentrated solar power systems, and combined heat and power (CHP) units where working fluid recycling enhances efficiency and reduces emissions. Industries such as aerospace, petroleum refining, and renewable energy utilize open cycle turbines for flexible and rapid energy production, while closed cycle turbines are preferred in environments requiring controlled atmospheres and high thermal efficiency.

Cost Analysis and Economic Considerations

Open Cycle Gas Turbines generally have lower initial capital costs and simpler designs, making them more economical for power plants with fluctuating demand and shorter operational hours. Closed Cycle Gas Turbines involve higher upfront investment due to complex heat exchangers and working fluid recirculation systems, but they offer improved thermal efficiency and fuel savings in continuous, high-load applications. Your choice depends on balancing upfront expenditure against long-term fuel costs and maintenance requirements, optimizing for operational efficiency and economic viability.

Future Trends and Technological Developments

Future trends in Open Cycle Gas Turbine (OCGT) technology emphasize increased fuel flexibility and integration with renewable energy sources to enhance grid stability and reduce carbon emissions. Closed Cycle Gas Turbine (CCGT) developments focus on advanced heat exchanger materials and working fluids like supercritical CO2 to improve thermal efficiency and lower operational costs. Both cycles are projected to benefit from digital twin technology and AI-driven predictive maintenance for optimized performance and reduced downtime.

Open Cycle Gas Turbine vs Closed Cycle Gas Turbine Infographic

libmatt.com

libmatt.com