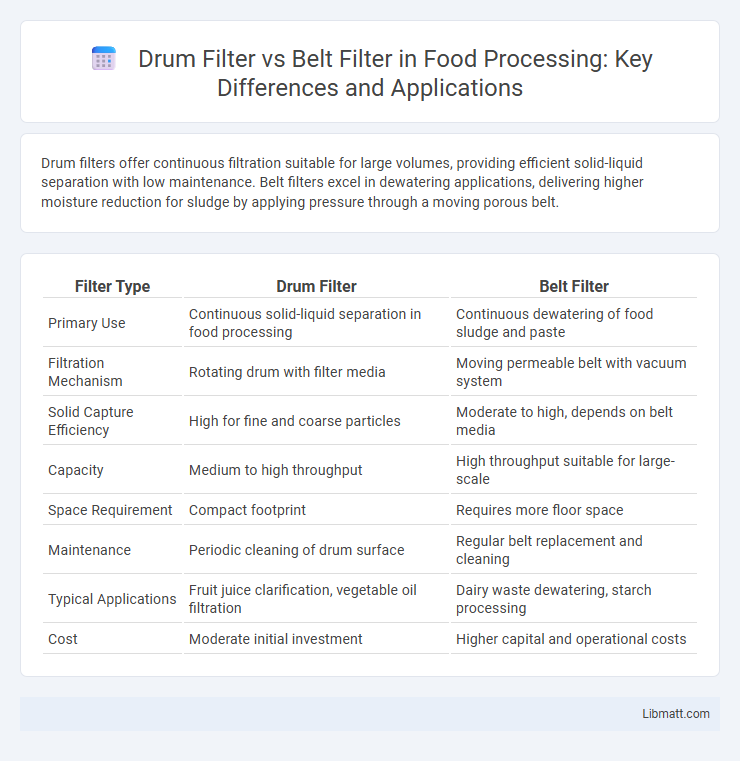

Drum filters offer continuous filtration suitable for large volumes, providing efficient solid-liquid separation with low maintenance. Belt filters excel in dewatering applications, delivering higher moisture reduction for sludge by applying pressure through a moving porous belt.

Table of Comparison

| Filter Type | Drum Filter | Belt Filter |

|---|---|---|

| Primary Use | Continuous solid-liquid separation in food processing | Continuous dewatering of food sludge and paste |

| Filtration Mechanism | Rotating drum with filter media | Moving permeable belt with vacuum system |

| Solid Capture Efficiency | High for fine and coarse particles | Moderate to high, depends on belt media |

| Capacity | Medium to high throughput | High throughput suitable for large-scale |

| Space Requirement | Compact footprint | Requires more floor space |

| Maintenance | Periodic cleaning of drum surface | Regular belt replacement and cleaning |

| Typical Applications | Fruit juice clarification, vegetable oil filtration | Dairy waste dewatering, starch processing |

| Cost | Moderate initial investment | Higher capital and operational costs |

Introduction to Drum and Belt Filters

Drum filters utilize a rotating drum covered with a filter medium to separate solids from liquids, making them ideal for continuous filtration in wastewater treatment and industrial processes. Belt filters operate by passing sludge between two moving belts that squeeze out water, offering efficient dewatering for high moisture-content materials. Your choice between these technologies depends on factors such as sludge characteristics, space availability, and required filtration capacity.

How Drum Filters Work

Drum filters operate by rotating a cylindrical mesh submerged partially in a slurry tank, where pressure differential causes liquid to pass through the mesh while solids accumulate on the drum surface. As the drum rotates, a vacuum system draws the filtrate through the mesh, enabling continuous separation of solids from liquids. This method ensures efficient filtration with minimal cake buildup, ideal for applications like wastewater treatment and pulp processing.

How Belt Filters Operate

Belt filters operate by continuously feeding a sludge slurry onto a moving porous filter belt that allows water to pass through while retaining solids. The sludge cake is progressively dewatered through a series of rollers applying increasing pressure, enhancing moisture removal efficiency. This method ensures consistent cake thickness and lower moisture content compared to drum filters, making belt filters ideal for thickening and dewatering applications in wastewater treatment plants.

Key Differences Between Drum and Belt Filters

Drum filters utilize a rotating drum covered with filter media to separate solids from liquids, offering continuous filtration and backwash cleaning for efficient operation in wastewater treatment. Belt filters operate with a moving porous belt that applies mechanical pressure to dewater sludge, making them ideal for high-solid-content applications. Your choice depends on factors like required throughput, sludge characteristics, and maintenance preferences, as drum filters excel in low-to-medium solids concentration, while belt filters handle higher solids more effectively.

Filtration Efficiency: Drum vs Belt

Drum filters typically offer higher filtration efficiency due to their continuous rotary design, which allows for effective removal of fine suspended solids and consistent washing of the filter media. Belt filters provide variable filtration efficiency, often depending on the type of media used and operational parameters, excelling in dewatering thick sludge but sometimes allowing finer particles to pass through. In industrial applications requiring precise solid-liquid separation, drum filters generally outperform belt filters in maintaining clarity and reducing turbidity in the filtrate.

Maintenance Requirements

Drum filters demand regular cleaning and periodic replacement of filter media to prevent clogging and maintain efficiency. Belt filters require consistent belt tension adjustments and scheduled wash cycles to avoid fabric wear and ensure optimal sludge dewatering performance. Both systems benefit from routine inspection of mechanical components to reduce downtime and extend operational lifespan.

Cost Comparison

Drum filters typically have a lower initial investment cost compared to belt filters due to simpler design and fewer mechanical components. Operating expenses for drum filters are generally higher because of increased maintenance needs and energy consumption linked to continuous rotation and cleaning processes. Belt filters, while more expensive upfront, offer cost savings over time through lower energy usage and reduced downtime, making them economically preferable for large-scale and continuous filtration operations.

Application Suitability

Drum filters are ideal for wastewater treatment plants with moderate solid loads, offering efficient continuous filtration and easy maintenance. Belt filters excel in industrial sludge dewatering where handling high volumes and achieving low moisture content is critical. Understanding your specific application needs ensures you select the filter that maximizes operational efficiency and cost-effectiveness.

Environmental Impact Considerations

Drum filters generally consume less water and energy compared to belt filters, reducing their overall environmental footprint in wastewater treatment applications. Belt filters often require more frequent chemical usage and generate higher volumes of sludge, leading to increased disposal challenges and potential environmental hazards. When selecting equipment for your facility, evaluating the sustainability of drum filters can contribute to minimizing resource consumption and lowering ecological impact.

Choosing the Right Filter for Your Needs

Selecting between a drum filter and a belt filter depends on your specific wastewater treatment requirements, flow rates, and solids load. Drum filters excel in continuous operation with moderate solids concentration, offering efficient filtration and easy maintenance, while belt filters handle higher solids loads and dewatering needs with robust, large-scale processing capabilities. Evaluate factors such as filtration area, cake dryness, operational costs, and footprint to determine the optimal solution for your industrial or municipal application.

drum filter vs belt filter Infographic

libmatt.com

libmatt.com