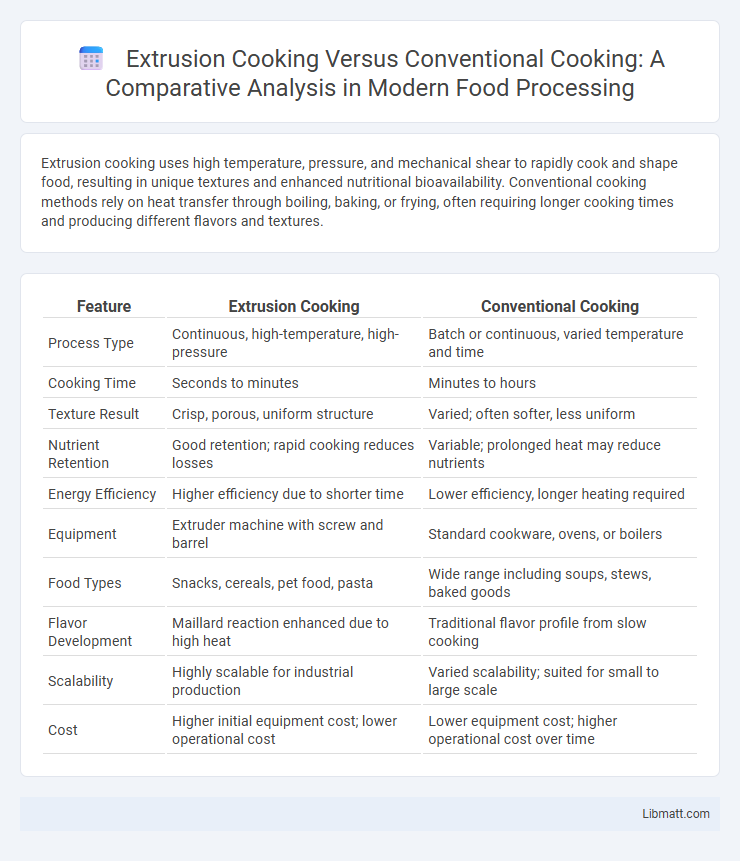

Extrusion cooking uses high temperature, pressure, and mechanical shear to rapidly cook and shape food, resulting in unique textures and enhanced nutritional bioavailability. Conventional cooking methods rely on heat transfer through boiling, baking, or frying, often requiring longer cooking times and producing different flavors and textures.

Table of Comparison

| Feature | Extrusion Cooking | Conventional Cooking |

|---|---|---|

| Process Type | Continuous, high-temperature, high-pressure | Batch or continuous, varied temperature and time |

| Cooking Time | Seconds to minutes | Minutes to hours |

| Texture Result | Crisp, porous, uniform structure | Varied; often softer, less uniform |

| Nutrient Retention | Good retention; rapid cooking reduces losses | Variable; prolonged heat may reduce nutrients |

| Energy Efficiency | Higher efficiency due to shorter time | Lower efficiency, longer heating required |

| Equipment | Extruder machine with screw and barrel | Standard cookware, ovens, or boilers |

| Food Types | Snacks, cereals, pet food, pasta | Wide range including soups, stews, baked goods |

| Flavor Development | Maillard reaction enhanced due to high heat | Traditional flavor profile from slow cooking |

| Scalability | Highly scalable for industrial production | Varied scalability; suited for small to large scale |

| Cost | Higher initial equipment cost; lower operational cost | Lower equipment cost; higher operational cost over time |

Introduction to Extrusion and Conventional Cooking

Extrusion cooking is a high-temperature, short-time process that combines mixing, cooking, and shaping in a single continuous operation, ideal for producing snacks, cereals, and pet food with enhanced texture and flavor. Conventional cooking involves slower heat transfer methods like boiling, steaming, or baking, which can lead to longer processing times and variable nutrient retention. Understanding these differences helps you choose the most efficient cooking technology for your food production needs.

Definition and Process of Extrusion Cooking

Extrusion cooking is a high-temperature, short-time process where ingredients are forced through a shaped die using a screw mechanism, resulting in cooked and expanded food products. Unlike conventional cooking, which relies on prolonged heating methods such as boiling or baking, extrusion combines cooking, mixing, and shaping into a single step, ensuring rapid starch gelatinization and protein denaturation. This efficient technique allows You to produce consistent textures and shapes in snacks, cereals, and pet foods, enhancing product quality and scalability.

Overview of Conventional Cooking Methods

Conventional cooking methods such as boiling, steaming, baking, and frying rely on gradual heat transfer to prepare food, often requiring longer cooking times and careful monitoring. These techniques typically preserve texture and flavor but may result in lower nutrient retention compared to advanced processes like extrusion cooking. Understanding these traditional methods helps you appreciate the efficiency and unique benefits extrusion cooking brings to modern food processing.

Key Differences Between Extrusion and Conventional Cooking

Extrusion cooking uses high temperature, pressure, and mechanical shear to rapidly cook and shape food products, while conventional cooking relies on slower methods like boiling or baking with direct heat transfer. Extrusion allows for continuous production, creating uniform textures and shapes, whereas conventional cooking is typically batch-based with variable product consistency. Your choice depends on desired product characteristics, production speed, and equipment investment.

Nutritional Impact: Extrusion vs Conventional Methods

Extrusion cooking preserves more nutrients such as vitamins, minerals, and dietary fiber compared to conventional cooking by minimizing exposure to water and reducing cooking time. The high temperature and pressure in extrusion can lead to partial degradation of sensitive vitamins but often enhance the bioavailability of certain nutrients like starch and protein. Conventional cooking often causes greater nutrient loss due to prolonged heat exposure and leaching of water-soluble vitamins during boiling or steaming.

Energy Efficiency and Processing Time Comparison

Extrusion cooking significantly reduces processing time by combining mixing, cooking, and shaping in one continuous operation, unlike conventional cooking which requires separate steps and longer durations. Energy efficiency in extrusion cooking is higher due to precise control over temperature and pressure, minimizing heat loss compared to conventional methods that rely on sustained external heating. Studies indicate extrusion cooking can save up to 30% energy and cut processing time by more than half, enhancing overall production efficiency.

Texture and Flavor Development in Both Methods

Extrusion cooking creates unique textures through high temperature and pressure, resulting in crispy, expanded products with enhanced flavor complexity due to Maillard reactions. Conventional cooking generally produces softer textures and more straightforward flavors, preserving natural food characteristics. Your choice between these methods impacts the sensory experience, with extrusion offering bold, crunchy textures and intensified flavors, while conventional cooking maintains traditional taste and mouthfeel.

Applications in Food Industry: Extrusion vs Conventional

Extrusion cooking is widely applied in the production of snacks, pet foods, breakfast cereals, and ready-to-eat meals due to its efficiency in shaping and texturizing ingredients under high temperature and pressure. Conventional cooking, used in baking, boiling, and frying, allows for more diverse flavor development and is preferred for traditional products requiring slow heat treatment. The choice between extrusion and conventional methods depends on desired product texture, processing speed, and ingredient compatibility within food manufacturing.

Environmental Sustainability: Pros and Cons

Extrusion cooking significantly reduces water and energy consumption compared to conventional cooking methods, contributing to lower greenhouse gas emissions and a smaller carbon footprint. However, the high initial energy input for extrusion equipment and potential for increased plastic packaging can offset some environmental benefits. Conventional cooking, while often less energy-intensive per batch, typically consumes more water and produces higher wastewater volumes, posing greater challenges for sustainable food production.

Conclusion: Choosing the Right Cooking Process

Extrusion cooking offers rapid processing, enhanced nutrient retention, and the ability to create diverse textures and shapes, making it ideal for large-scale food manufacturing and specialized product development. Conventional cooking excels in flavor development and traditional recipes, providing a familiar taste profile but often requires longer cooking times and higher energy use. Your choice depends on the desired product characteristics, production scale, and nutritional goals, with extrusion cooking favored for efficiency and innovation, while conventional methods suit artisanal and flavor-rich dishes.

Extrusion Cooking vs Conventional Cooking Infographic

libmatt.com

libmatt.com