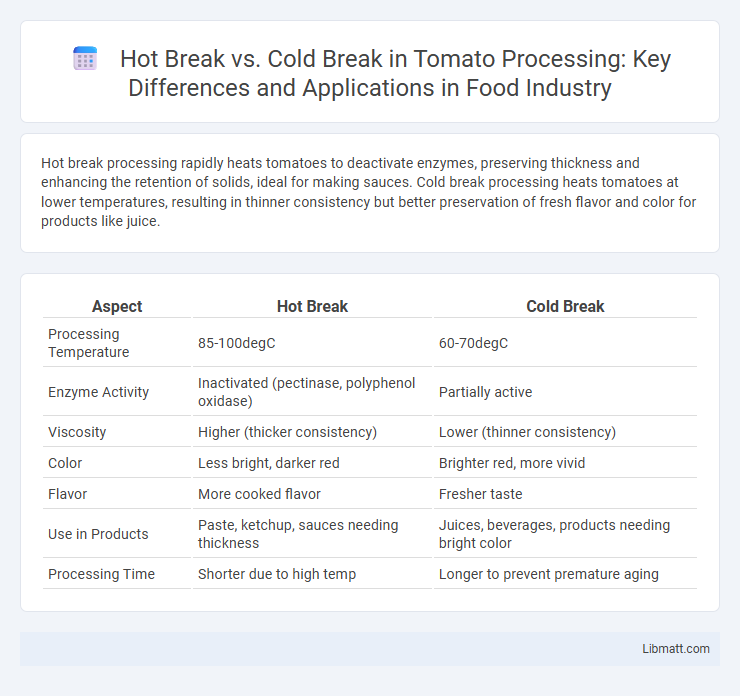

Hot break processing rapidly heats tomatoes to deactivate enzymes, preserving thickness and enhancing the retention of solids, ideal for making sauces. Cold break processing heats tomatoes at lower temperatures, resulting in thinner consistency but better preservation of fresh flavor and color for products like juice.

Table of Comparison

| Aspect | Hot Break | Cold Break |

|---|---|---|

| Processing Temperature | 85-100degC | 60-70degC |

| Enzyme Activity | Inactivated (pectinase, polyphenol oxidase) | Partially active |

| Viscosity | Higher (thicker consistency) | Lower (thinner consistency) |

| Color | Less bright, darker red | Brighter red, more vivid |

| Flavor | More cooked flavor | Fresher taste |

| Use in Products | Paste, ketchup, sauces needing thickness | Juices, beverages, products needing bright color |

| Processing Time | Shorter due to high temp | Longer to prevent premature aging |

Introduction to Tomato Processing

Tomato processing involves critical thermal steps known as hot break and cold break, which significantly impact product quality and texture. Hot break processing heats tomatoes rapidly to 85-100degC, preserving pectin and resulting in thicker sauces with higher viscosity. Cold break processing heats tomatoes to a lower temperature range of 65-75degC, retaining more natural flavor and color but producing thinner juices and sauces with less pectin content.

Defining Hot Break and Cold Break Methods

Hot break and cold break methods are critical processes in tomato processing that influence texture and flavor. Hot break involves heating tomatoes to 85-100degC immediately after crushing to inactivate enzymes, preserving pectin and resulting in thicker, more viscous products like sauces and pastes. Cold break heats tomatoes to a lower temperature, around 60-70degC, to retain fresh flavor and color while producing thinner juices or purees, ideal for products that emphasize a fresher taste.

Key Differences Between Hot Break and Cold Break

Hot break and cold break are critical methods in tomato processing that significantly affect product quality and nutrient retention. Hot break involves rapid heating of tomatoes to 85-100degC, which inactivates enzymes like pectinase, preserving viscosity and resulting in thicker tomato pastes and sauces. Cold break heats tomatoes to a lower temperature range of 60-70degC, retaining more volatile aroma compounds and a fresher taste but leading to thinner consistency due to partial enzyme activity.

Impact on Tomato Product Quality

Hot break processing in tomato production rapidly heats tomatoes to deactivate enzymes, preserving a thicker texture and richer color, which enhances the quality of ketchup and sauces. Cold break processing involves slower heating, resulting in higher juice yields and a lighter color, ideal for tomato juice and paste with a fresher taste profile. The choice between hot and cold break significantly influences viscosity, color retention, and nutrient stability, directly affecting the final product's sensory attributes and shelf life.

Influence on Viscosity and Texture

Hot break tomato processing involves heating tomatoes to 85-100degC immediately after crushing, which inactivates enzymes like pectinase, preserving pectin structure and resulting in higher viscosity and thicker texture. Cold break processing heats tomatoes to 60-70degC, allowing partial enzyme activity that breaks down pectin, yielding a thinner consistency and smoother texture. The choice between hot and cold break methods directly influences the final viscosity and mouthfeel of tomato products such as sauces and pastes.

Color and Flavor Retention in Both Methods

Hot break tomato processing involves heating tomatoes to 85-100degC, effectively preserving vibrant color and rich flavor by inactivating enzymes that cause degradation. Cold break processing heats tomatoes at lower temperatures around 60-70degC, resulting in a lighter color and fresher, more acidic flavor due to partial enzyme activity. Your choice between hot break and cold break impacts the balance of color intensity and flavor freshness in the final tomato product.

Application Suitability: When to Use Hot Break vs Cold Break

Hot break tomato processing is ideal for products requiring thicker consistency and higher viscosity, such as ketchup and tomato paste, due to its rapid heating that preserves pectin structure. Cold break is better suited for juices, sauces, and canned whole tomatoes where a fresher taste and lighter texture are desired, as it involves slower heating that reduces pectin breakdown. Choose hot break for recipes needing robust texture and cold break when maintaining fresh flavor and color is your priority.

Equipment and Processing Requirements

Hot break tomato processing requires high-temperature equipment such as steam-jacketed kettles or continuous steam cookers to rapidly heat tomatoes to around 85-100degC, preserving pectin and resulting in thicker sauces. Cold break processing uses lower temperatures, typically below 65degC, necessitating gentle heating systems like plate heat exchangers to minimize pectin degradation and maintain a fresher flavor. Choosing the right equipment impacts your control over texture and viscosity in the final tomato product.

Industrial Trends and Innovations

Industrial trends in tomato processing show a growing preference for hot break methods due to enhanced paste viscosity and nutrient retention, which align with increased consumer demand for natural, high-quality products. Innovations in thermal technology, such as precise temperature control and rapid heating systems, improve efficiency and product consistency while reducing energy consumption. Cold break processes continue to evolve with advanced membrane filtration techniques that preserve flavor and color, catering to niche markets requiring fresh-like tomato products.

Conclusion: Choosing the Optimal Break Method

Selecting the optimal break method in tomato processing depends on your desired product quality and production efficiency. Hot break preserves pectin and produces thicker sauces ideal for paste and ketchup, while cold break retains more fresh flavor and nutrients, perfect for juices and soups. Your choice impacts texture, viscosity, and flavor, ensuring the final product meets market expectations.

hot break vs cold break in tomato processing Infographic

libmatt.com

libmatt.com