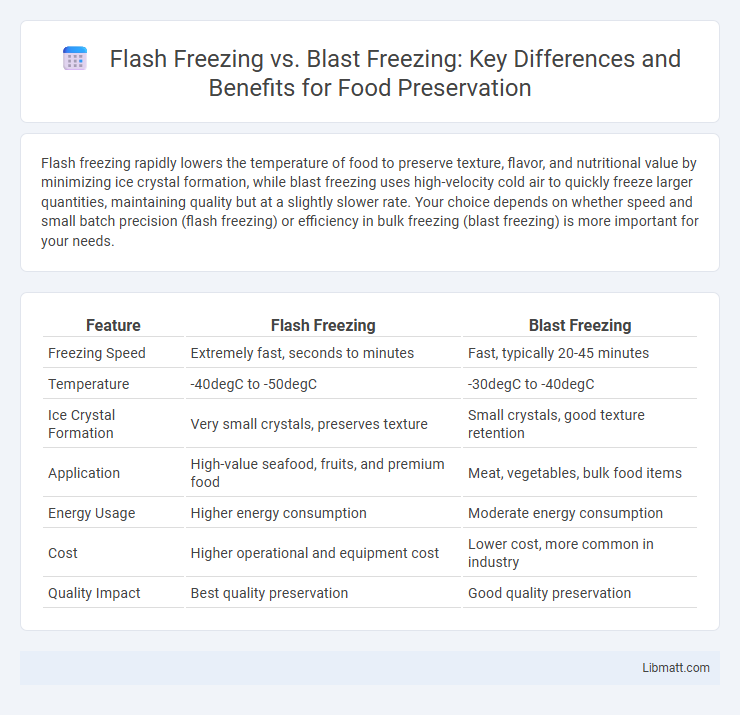

Flash freezing rapidly lowers the temperature of food to preserve texture, flavor, and nutritional value by minimizing ice crystal formation, while blast freezing uses high-velocity cold air to quickly freeze larger quantities, maintaining quality but at a slightly slower rate. Your choice depends on whether speed and small batch precision (flash freezing) or efficiency in bulk freezing (blast freezing) is more important for your needs.

Table of Comparison

| Feature | Flash Freezing | Blast Freezing |

|---|---|---|

| Freezing Speed | Extremely fast, seconds to minutes | Fast, typically 20-45 minutes |

| Temperature | -40degC to -50degC | -30degC to -40degC |

| Ice Crystal Formation | Very small crystals, preserves texture | Small crystals, good texture retention |

| Application | High-value seafood, fruits, and premium food | Meat, vegetables, bulk food items |

| Energy Usage | Higher energy consumption | Moderate energy consumption |

| Cost | Higher operational and equipment cost | Lower cost, more common in industry |

| Quality Impact | Best quality preservation | Good quality preservation |

Introduction to Flash Freezing and Blast Freezing

Flash freezing rapidly cools items by exposing them to extremely low temperatures at a high velocity, effectively preserving the texture and nutritional value of food by minimizing ice crystal formation. Blast freezing employs powerful blasts of cold air circulated at high speeds within a freezing chamber, freezing products quickly and uniformly for extended shelf life. Understanding these methods helps you select the optimal freezing technique based on your product's sensitivity and storage needs.

Understanding the Freezing Processes

Flash freezing involves rapidly lowering the temperature of food to preserve cellular structure and nutrient content, minimizing ice crystal formation that can damage texture. Blast freezing uses powerful blasts of cold air to freeze products quickly and uniformly, which is ideal for bulk processing in commercial settings. Understanding these processes helps you choose the best method to maintain food quality and extend shelf life.

Key Differences Between Flash Freezing and Blast Freezing

Flash freezing rapidly lowers the temperature of food to preserve the cellular structure and nutritional content by freezing it within minutes, often at temperatures below -30degF (-34degC). Blast freezing uses cold air circulation at temperatures around -10degF to -40degF (-23degC to -40degC) to freeze food more gradually than flash freezing, which helps in maintaining texture but may allow larger ice crystals to form. The key differences lie in freezing speed, temperature, and impact on food quality, with flash freezing providing quicker preservation and smaller ice crystals compared to the slower process of blast freezing.

Temperature Ranges and Speed of Freezing

Flash freezing typically occurs at temperatures around -40degF to -50degF, rapidly freezing small food items in minutes to preserve cellular structure and minimize ice crystal formation. Blast freezing operates at slightly warmer temperatures, usually between -10degF and -30degF, and uses high-velocity cold air to freeze larger quantities of food more quickly than standard freezing methods but slower than flash freezing. The faster freezing speed and lower temperature range of flash freezing result in superior texture and quality retention compared to the broader temperature and slower process of blast freezing.

Equipment and Technology Used

Flash freezing utilizes specialized cryogenic equipment, such as liquid nitrogen or carbon dioxide-based freezers, to rapidly lower the temperature of products within minutes. Blast freezing employs high-velocity cold air circulated by powerful fans in blast freezers, reaching temperatures typically between -30degC and -40degC to freeze food quickly. Both technologies require precise temperature control systems and insulation to maintain consistent freezing conditions and preserve product quality.

Impact on Food Quality and Texture

Flash freezing preserves food quality by rapidly lowering temperature, minimizing ice crystal formation that can damage cellular structure and cause texture loss. Blast freezing, while fast, cools food at a slower rate than flash freezing, potentially resulting in larger ice crystals that degrade texture and flavor. Your choice between these methods affects the final product's freshness, moisture retention, and overall sensory experience.

Applications in Food Industries

Flash freezing preserves the quality and nutritional value of seafood, fruits, and vegetables by rapidly reducing the temperature to prevent large ice crystals from forming, making it ideal for delicate items. Blast freezing, commonly used for meat and poultry, utilizes high-velocity cold air to quickly freeze products in bulk, maintaining texture and minimizing microbial growth during storage. Your choice of freezing method impacts product shelf life, texture, and overall food safety in industrial food processing.

Energy Efficiency and Cost Considerations

Flash freezing consumes less energy by rapidly reducing food temperature with minimal ice crystal formation, preserving product quality efficiently. Blast freezing requires higher energy input to maintain strong airflow at very low temperatures, leading to increased operational costs over time. You should evaluate your facility's energy rates and freezing volume to optimize cost-effectiveness between these two methods.

Safety and Regulatory Standards

Flash freezing and blast freezing both adhere to stringent safety and regulatory standards established by agencies such as the FDA and USDA to ensure food quality and safety. Flash freezing rapidly lowers the temperature of food to -30degF or lower within minutes, minimizing ice crystal formation and reducing microbial growth, thereby meeting HACCP guidelines for pathogen control. Blast freezing, while slightly slower in temperature reduction (typically to -20degF), also complies with critical control point regulations and maintains product integrity by preventing spoilage and contamination during storage and transport.

Choosing the Right Freezing Method for Your Needs

Choosing the right freezing method depends on the type and volume of food you need to preserve. Flash freezing rapidly freezes individual items to prevent ice crystal formation, making it ideal for delicate foods like fruits and seafood, while blast freezing uses powerful cold air circulation to freeze bulk quantities quickly and uniformly. Understanding your freezing goals and food properties ensures you select the most efficient method to maintain quality and extend shelf life.

Flash Freezing vs Blast Freezing Infographic

libmatt.com

libmatt.com