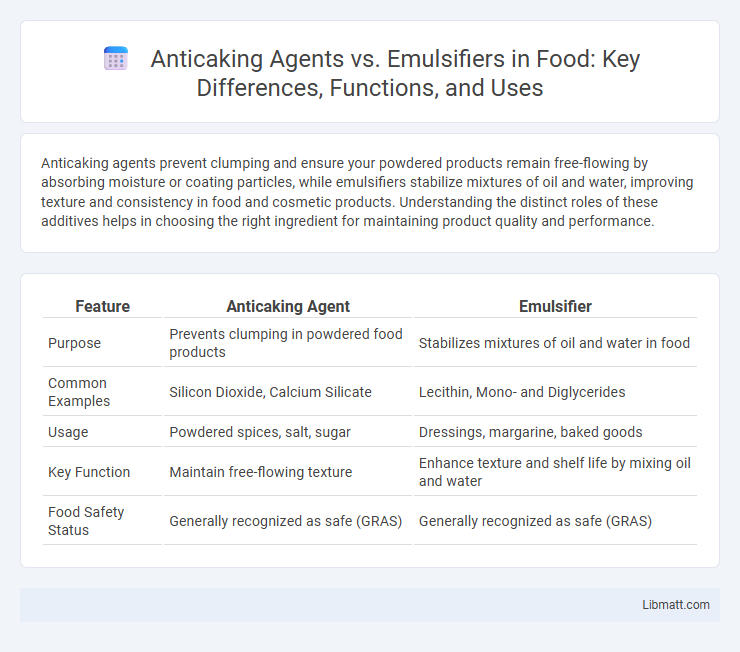

Anticaking agents prevent clumping and ensure your powdered products remain free-flowing by absorbing moisture or coating particles, while emulsifiers stabilize mixtures of oil and water, improving texture and consistency in food and cosmetic products. Understanding the distinct roles of these additives helps in choosing the right ingredient for maintaining product quality and performance.

Table of Comparison

| Feature | Anticaking Agent | Emulsifier |

|---|---|---|

| Purpose | Prevents clumping in powdered food products | Stabilizes mixtures of oil and water in food |

| Common Examples | Silicon Dioxide, Calcium Silicate | Lecithin, Mono- and Diglycerides |

| Usage | Powdered spices, salt, sugar | Dressings, margarine, baked goods |

| Key Function | Maintain free-flowing texture | Enhance texture and shelf life by mixing oil and water |

| Food Safety Status | Generally recognized as safe (GRAS) | Generally recognized as safe (GRAS) |

Introduction to Anticaking Agents and Emulsifiers

Anticaking agents prevent powder clumping by absorbing moisture and improving flow properties in products such as salt, sugar, and powdered milk. Emulsifiers stabilize mixtures of immiscible liquids like oil and water, enabling consistent textures in foods such as mayonnaise and salad dressings. Both additives play distinct roles in enhancing food quality and shelf life through targeted chemical interactions.

Definition of Anticaking Agents

Anticaking agents are additives used in powdered or granulated products to prevent clumping and ensure free-flowing texture by inhibiting moisture absorption and aggregation. These agents, commonly found in salt, powdered sugar, and spices, help maintain product quality and ease of use during storage and handling. Understanding the role of anticaking agents can help you optimize your product's consistency and shelf life compared to emulsifiers, which primarily stabilize mixtures of oil and water.

Definition of Emulsifiers

Emulsifiers are additives that stabilize mixtures of oil and water by reducing surface tension, enabling uniform dispersion of immiscible liquids. Unlike anticaking agents, which prevent clumping in powdered substances, emulsifiers improve texture and consistency in processed foods. Common emulsifiers include lecithin, mono- and diglycerides, and polysorbates.

How Anticaking Agents Work

Anticaking agents function by absorbing excess moisture or coating particles to prevent clumping in powdered and granulated products, ensuring free-flowing consistency during storage and handling. Common substances such as silicon dioxide, calcium silicate, and tricalcium phosphate create a physical barrier that inhibits moisture absorption and particle aggregation. Their role is critical in food industries, pharmaceuticals, and cosmetics where maintaining product texture and ease of use is essential.

How Emulsifiers Function

Emulsifiers function by reducing surface tension between immiscible liquids, such as oil and water, allowing them to form a stable mixture or emulsion. These molecules contain both hydrophilic (water-attracting) and lipophilic (fat-attracting) properties, enabling them to surround and stabilize droplets within the mixture. By preventing separation, emulsifiers improve the texture, consistency, and shelf-life of products like salad dressings, mayonnaise, and baked goods.

Key Differences Between Anticaking Agents and Emulsifiers

Anticaking agents prevent clumping in powdered or granulated substances by absorbing moisture, ensuring free-flowing texture and ease of use in products like salt, powdered sugar, and spices. Emulsifiers stabilize mixtures of immiscible liquids such as oil and water, maintaining homogeneous consistency in products like mayonnaise, dressings, and baked goods. The key difference lies in their functional role: anticaking agents control moisture-induced aggregation, while emulsifiers facilitate the blending of incompatible liquids to improve texture and shelf life.

Common Applications in the Food Industry

Anticaking agents are commonly used in powdered food products such as salt, spices, and powdered sugar to prevent clumping and ensure free flow during packaging and usage. Emulsifiers play a crucial role in processed foods like mayonnaise, ice cream, and baked goods by stabilizing mixtures of oil and water to improve texture and consistency. Understanding these differences helps you select the right additive for maintaining product quality in various food applications.

Safety and Regulatory Considerations

Anticaking agents and emulsifiers undergo rigorous safety assessments and are regulated by food safety authorities such as the FDA and EFSA to ensure their safe use in food products. Your choice between the two must consider their permitted usage levels, approved applications, and potential allergenic effects as outlined in regulatory guidelines. Understanding these safety and regulatory considerations helps maintain compliance and protect consumer health.

Benefits and Limitations of Each Additive

Anticaking agents improve powder flow and prevent clumping in dry products, enhancing shelf life and ease of use but may alter texture and sometimes impart a slight taste. Emulsifiers stabilize mixtures of oil and water, improving product consistency and texture while extending freshness, though excessive use can lead to unwanted flavors or digestive discomfort. Both additives serve distinct functional roles with benefits tailored to specific food formulations, yet their limitations require careful dosage and selection to maintain product quality.

Conclusion: Choosing the Right Additive

Choosing the right additive depends on your product's specific needs: anticaking agents prevent clumping in powders and maintain free-flowing texture, while emulsifiers stabilize mixtures of oil and water to ensure consistent texture and appearance. Understanding the functional difference helps optimize product quality and shelf life. Your selection impacts both manufacturing efficiency and consumer experience.

Anticaking Agent vs Emulsifier Infographic

libmatt.com

libmatt.com