Enrobing involves coating products, typically chocolates or candies, by passing them through a curtain of melted coating to create a uniform layer, while panning refers to tumbling items in a rotating drum to apply layers of sugar, chocolate, or other coatings. Your choice between enrobing and panning depends on the desired finish and texture of the final product, as enrobing offers a smooth, consistent coating and panning provides a thicker, layered appearance.

Table of Comparison

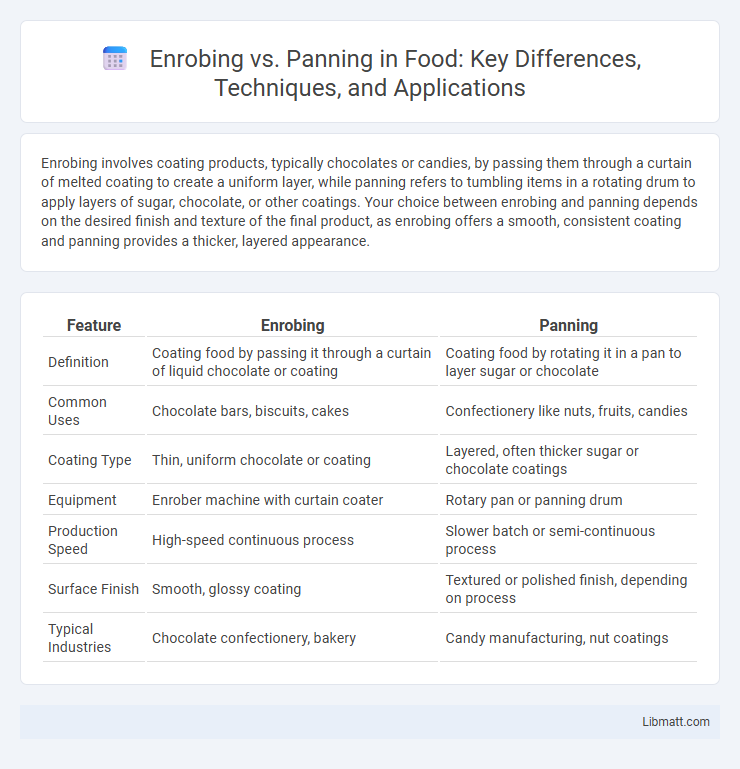

| Feature | Enrobing | Panning |

|---|---|---|

| Definition | Coating food by passing it through a curtain of liquid chocolate or coating | Coating food by rotating it in a pan to layer sugar or chocolate |

| Common Uses | Chocolate bars, biscuits, cakes | Confectionery like nuts, fruits, candies |

| Coating Type | Thin, uniform chocolate or coating | Layered, often thicker sugar or chocolate coatings |

| Equipment | Enrober machine with curtain coater | Rotary pan or panning drum |

| Production Speed | High-speed continuous process | Slower batch or semi-continuous process |

| Surface Finish | Smooth, glossy coating | Textured or polished finish, depending on process |

| Typical Industries | Chocolate confectionery, bakery | Candy manufacturing, nut coatings |

Introduction to Enrobing and Panning

Enrobing involves coating a center, such as a confection or nut, with a continuous layer of chocolate or candy by passing it through a chocolate curtain. Panning, in contrast, gradually applies thin layers of chocolate, sugar, or other coatings to centers by tumbling them in a rotating drum, allowing for even and multiple-layer builds. Your choice between enrobing and panning depends on the desired texture and appearance of the final product.

Understanding the Enrobing Process

The enrobing process involves coating confectionery items by continuously passing them through a curtain of melted chocolate, ensuring an even and smooth layer on all sides. This method is ideal for products with irregular shapes, as the liquid chocolate fully covers the item before it solidifies. Precision in temperature and flow control during enrobing is crucial for achieving consistent texture and sheen in premium chocolate coatings.

The Panning Technique Explained

The panning technique involves tumbling confections in a rotating drum to create a uniform coating, typically using sugar, chocolate, or syrup layers. This method allows precise control over the thickness and texture of the coating, making it ideal for products like candy shells or chocolate-covered nuts. Compared to enrobing, panning offers enhanced surface smoothness and durability due to its gradual layering process.

Key Differences Between Enrobing and Panning

Enrobing involves coating confections by pouring or flowing melted chocolate over them, creating a smooth and even layer, whereas panning is a process of tumbling centers in a rotating drum while gradually adding coatings like sugar or chocolate to build up multiple layers. The key difference lies in the method and texture outcome: enrobing produces a thin, uniform coating, while panning creates thicker, layered finishes, often with a glossy or crunchy surface. Understanding these distinctions helps you choose the ideal technique for desired appearance, texture, and production efficiency in confectionery manufacturing.

Material Compatibility: What Products Work Best

Enrobing works best with softer, moisture-sensitive products such as cakes, pastries, and confections that require a thin, even chocolate or coating layer, ensuring smooth coverage without damaging delicate textures. Panning is ideal for hard or solid centers like nuts, candies, and dried fruits, as it applies thicker, multi-layered coatings that enhance durability and flavor encapsulation. Your choice between enrobing and panning depends on the compatibility of the coating process with the physical characteristics of your product.

Equipment and Technology Used

Enrobing equipment features a continuous curtain of coating material that flows over products on a conveyor belt, utilizing specialized nozzles and heating systems for uniform coverage. Panning machines rely on rotating drums or pans where products are tumbled and coated layer by layer, often integrated with air blowers and syrup injectors for precision application. Advanced enrobing technology allows for faster coating times and smoother finishes, while modern panning equipment excels in creating layered textures and varied surface treatments.

Advantages of Enrobing

Enrobing offers precise control over coating thickness and consistency, making it ideal for delicate confectionery products. This technique enhances the visual appeal and texture while providing a uniform chocolate layer that improves shelf life. You benefit from faster production speeds and reduced chocolate waste compared to panning, optimizing efficiency in your manufacturing process.

Benefits of Panning

Panning offers precise coating control, ensuring an even and consistent layer on chocolates or candies by using a rotating pan. This technique enhances product durability by providing a smooth, glossy finish that resists moisture and improves shelf life. Panning also allows for automated production, increasing efficiency and scalability in confectionery manufacturing.

Choosing the Right Method for Your Product

Enrobing suits products requiring a thin, even chocolate coating, ideal for items like bars and biscuits, ensuring smooth coverage and faster production. Panning excels with small, hard-centered items such as nuts and candies, providing a thick, polished shell through successive layers and tumbling action. Selecting the right method depends on product size, desired coating thickness, and texture, optimizing appearance and consumer appeal.

Industry Applications and Future Trends

Enrobing and panning serve distinct roles in confectionery and snack manufacturing, with enrobing primarily used for coating products like bars, biscuits, and ice cream with chocolate or other coatings, while panning is ideal for candy centers and nuts, creating smooth and diversified textures. The food industry leverages enrobing for mass production efficiency and uniform coatings, whereas panning offers intricate layering and shell development for gourmet or niche products. Emerging trends indicate increased automation, digital monitoring, and sustainable ingredient use, enhancing precision and eco-friendliness, while customization technology allows your brand to meet evolving consumer demands in both applications.

Enrobing vs Panning Infographic

libmatt.com

libmatt.com