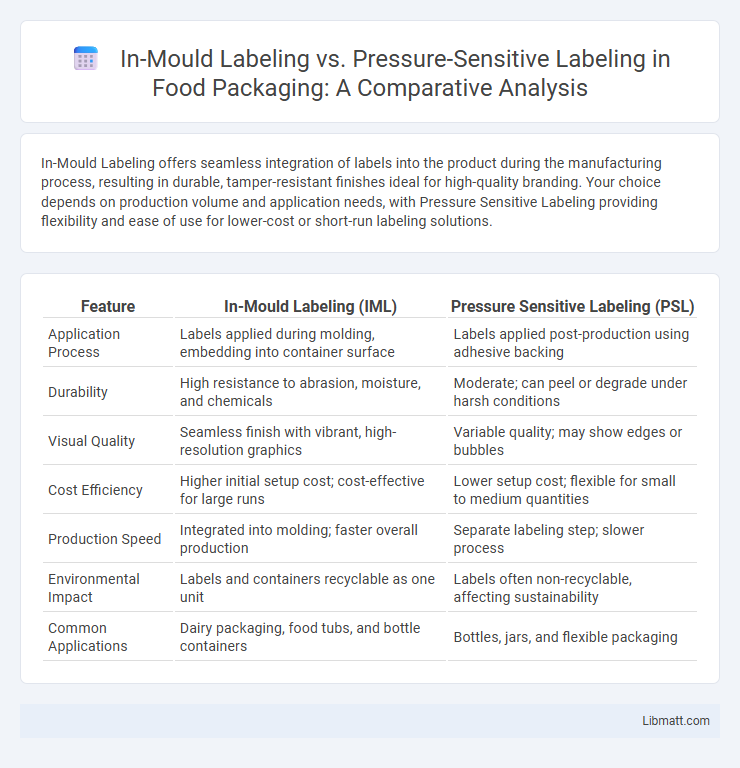

In-Mould Labeling offers seamless integration of labels into the product during the manufacturing process, resulting in durable, tamper-resistant finishes ideal for high-quality branding. Your choice depends on production volume and application needs, with Pressure Sensitive Labeling providing flexibility and ease of use for lower-cost or short-run labeling solutions.

Table of Comparison

| Feature | In-Mould Labeling (IML) | Pressure Sensitive Labeling (PSL) |

|---|---|---|

| Application Process | Labels applied during molding, embedding into container surface | Labels applied post-production using adhesive backing |

| Durability | High resistance to abrasion, moisture, and chemicals | Moderate; can peel or degrade under harsh conditions |

| Visual Quality | Seamless finish with vibrant, high-resolution graphics | Variable quality; may show edges or bubbles |

| Cost Efficiency | Higher initial setup cost; cost-effective for large runs | Lower setup cost; flexible for small to medium quantities |

| Production Speed | Integrated into molding; faster overall production | Separate labeling step; slower process |

| Environmental Impact | Labels and containers recyclable as one unit | Labels often non-recyclable, affecting sustainability |

| Common Applications | Dairy packaging, food tubs, and bottle containers | Bottles, jars, and flexible packaging |

Introduction to Labeling Technologies

In-mould labeling (IML) integrates the label directly into the plastic mold during manufacturing, creating a durable and seamless decoration that resists wear and fading. Pressure sensitive labeling (PSL) involves applying pre-printed adhesive labels to the product surface, offering flexibility and cost-efficiency for short runs and variable designs. Both technologies play crucial roles in packaging, with IML favored for high-volume production and premium appearance, while PSL excels in versatility and rapid application.

What is In-Mould Labeling?

In-Mould Labeling (IML) is a manufacturing process where labels are integrated directly into plastic containers during the molding cycle, creating a seamless and durable bond. This technique enhances label durability, resistance to wear and moisture, and offers superior graphics quality compared to Pressure Sensitive Labeling (PSL). Your products benefit from a high-quality, long-lasting appearance without the risk of label peeling or fading.

What is Pressure Sensitive Labeling?

Pressure Sensitive Labeling utilizes adhesives that bond labels to surfaces upon applying light pressure, eliminating the need for heat or water activation. This method offers rapid application, flexibility in label design, and strong adhesion to various substrates, making it ideal for diverse packaging needs. Your choice of Pressure Sensitive Labeling ensures efficient labeling with durable, customizable results suitable for both high-speed production lines and short runs.

Material Compatibility and Application Processes

In-Mould Labeling (IML) offers superior material compatibility by integrating labels directly into the mold during the plastic injection process, ensuring a seamless bond with materials such as polypropylene and polyethylene. Pressure Sensitive Labeling (PSL) relies on adhesives to adhere labels post-production, making it versatile for various substrates but potentially less durable on flexible or textured surfaces. Your choice between IML and PSL should consider the compatibility with the base material and the application process efficiency required for your production line.

Design Flexibility and Customization

In-mould labeling offers superior design flexibility by allowing full integration of labels into the product's surface, enabling complex shapes and seamless finishes ideal for high-quality, durable branding. Pressure sensitive labeling provides rapid customization opportunities with a wide range of materials, finishes, and adhesives, making it suitable for short runs and frequent design changes. Both methods support vibrant graphics, but in-mould labeling excels in scratch resistance while pressure sensitive labels offer easier on-demand design adjustments.

Durability and Resistance Comparison

In-mould labeling (IML) offers exceptional durability and resistance by fusing the label directly into the plastic container, ensuring it withstands harsh environments, abrasion, and chemicals without peeling or fading. Pressure sensitive labeling (PSL) relies on adhesive bonding, which is more susceptible to damage from moisture, temperature fluctuations, and physical wear over time. Consequently, IML provides superior resistance for applications demanding long-lasting, high-quality labels, while PSL is better suited for short-term or less rigorous conditions.

Production Speed and Efficiency

In-mould labeling (IML) significantly enhances production speed and efficiency by integrating the labeling process directly into the molding cycle, reducing handling and application steps compared to pressure sensitive labeling (PSL). IML eliminates drying time and label misalignment issues, allowing for continuous high-speed production with minimal downtime. In contrast, PSL requires slower application rates and additional curing stages, making it less efficient for large-scale manufacturing where speed and consistency are critical.

Cost Analysis and Investment Considerations

In-mould labeling (IML) typically involves higher upfront investment costs due to the need for specialized molds and integration with the molding process, but it offers long-term cost savings by reducing labor and secondary labeling expenses. Pressure sensitive labeling (PSL) requires lower initial investment and flexible application on different substrates but incurs ongoing costs for label materials and adhesives, as well as slower production rates. Companies must evaluate production volume, label durability, and budget constraints when deciding between IML's higher initial capital outlay with operational efficiency and PSL's lower entry barrier with variable cost structure.

Environmental Impact and Sustainability

In-Mould Labeling (IML) offers superior environmental benefits by integrating the label into the product during manufacturing, reducing waste and enhancing recyclability compared to Pressure Sensitive Labeling (PSL), which often uses adhesives that complicate recycling processes. IML minimizes plastic use and contamination, supporting circular economy goals with less energy and material consumption in production. Your choice of IML can significantly improve sustainability by lowering the carbon footprint associated with packaging and promoting more efficient waste management systems.

Choosing the Right Labeling Method for Your Product

Choosing the right labeling method for your product depends on factors such as durability, production speed, and cost-efficiency. In-Mould Labeling (IML) offers superior resistance to wear and is ideal for products requiring a seamless, tamper-proof finish, especially in high-volume manufacturing. Pressure Sensitive Labeling (PSL) provides flexibility and ease of application, making it suitable for smaller runs or products needing frequent label changes.

In-Mould Labeling vs Pressure Sensitive Labeling Infographic

libmatt.com

libmatt.com