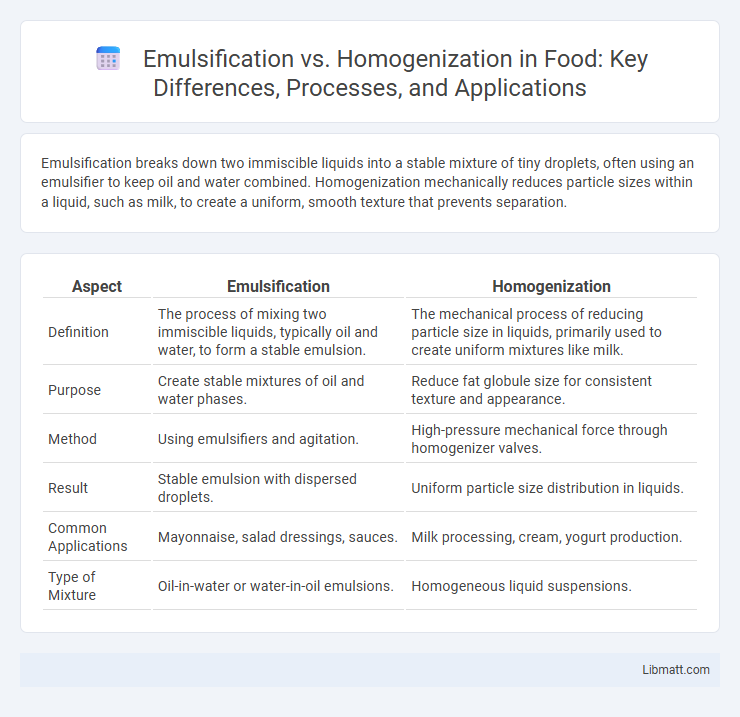

Emulsification breaks down two immiscible liquids into a stable mixture of tiny droplets, often using an emulsifier to keep oil and water combined. Homogenization mechanically reduces particle sizes within a liquid, such as milk, to create a uniform, smooth texture that prevents separation.

Table of Comparison

| Aspect | Emulsification | Homogenization |

|---|---|---|

| Definition | The process of mixing two immiscible liquids, typically oil and water, to form a stable emulsion. | The mechanical process of reducing particle size in liquids, primarily used to create uniform mixtures like milk. |

| Purpose | Create stable mixtures of oil and water phases. | Reduce fat globule size for consistent texture and appearance. |

| Method | Using emulsifiers and agitation. | High-pressure mechanical force through homogenizer valves. |

| Result | Stable emulsion with dispersed droplets. | Uniform particle size distribution in liquids. |

| Common Applications | Mayonnaise, salad dressings, sauces. | Milk processing, cream, yogurt production. |

| Type of Mixture | Oil-in-water or water-in-oil emulsions. | Homogeneous liquid suspensions. |

Understanding Emulsification: Definition and Process

Emulsification is the process of mixing two immiscible liquids, typically oil and water, to create a stable mixture called an emulsion. This process involves the dispersion of one liquid into another in the form of tiny droplets, often aided by emulsifiers that reduce surface tension and prevent separation. Emulsification is crucial in food production, cosmetics, and pharmaceuticals for achieving uniform texture and consistency.

What is Homogenization? Key Concepts Explained

Homogenization is a mechanical process that breaks down fat molecules in liquids, such as milk, to create a uniform and stable mixture by evenly dispersing fat globules throughout the liquid. This process enhances texture, taste, and shelf life by preventing the separation of components, ensuring consistent quality in dairy products and other emulsified systems. Understanding homogenization helps you improve product stability and optimize manufacturing processes in food and cosmetic industries.

The Science Behind Emulsification

Emulsification involves the dispersion of two immiscible liquids, such as oil and water, into a stable mixture using emulsifying agents that reduce surface tension at the interface. This process relies on the formation of small droplets stabilized by surfactants or phospholipids, preventing phase separation through steric or electrostatic repulsion. Emulsification differs from homogenization, which mechanically breaks down particles into uniform sizes but does not inherently stabilize the dispersed phase chemically.

How Homogenization Works: Mechanisms and Methods

Homogenization works by applying mechanical forces such as high pressure, shearing, and turbulence to break down fat globules into smaller, uniformly distributed particles, preventing separation. Common methods include high-pressure homogenizers, ultrasonic homogenization, and microfluidization, each utilizing different mechanisms to achieve a stable and consistent emulsion. This process enhances product texture, stability, and shelf life in industries like dairy, pharmaceuticals, and cosmetics.

Key Differences Between Emulsification and Homogenization

Emulsification involves mixing two immiscible liquids, such as oil and water, to form a stable mixture called an emulsion, typically requiring emulsifiers to maintain stability. Homogenization is a mechanical process that reduces particle size and distributes droplets evenly, commonly used in dairy to achieve uniform texture and prevent separation. The key difference lies in emulsification creating a stable mixture of distinct phases with emulsifiers, while homogenization physically breaks down and disperses particles for consistency.

Common Applications in Food and Beverage Industries

Emulsification is widely used in the production of salad dressings, mayonnaise, and sauces to combine oil and water phases into stable mixtures, enhancing texture and flavor consistency. Homogenization is essential in dairy processing, particularly for milk and cream, to break down fat globules and prevent separation, improving shelf life and mouthfeel. Both techniques are critical in beverage manufacturing, such as fruit juices and flavored drinks, to maintain uniform particle dispersion and overall product stability.

Equipment Used in Emulsification vs Homogenization

Emulsification typically uses high-shear mixers, ultrasonic homogenizers, or rotor-stator devices designed to blend immiscible liquids into stable emulsions by reducing droplet size. Homogenization employs specialized homogenizers such as high-pressure valve homogenizers or piston-gap homogenizers that force the mixture through narrow spaces to achieve uniform particle or droplet distribution. Equipment differences reflect process goals: emulsification emphasizes droplet dispersion and stability, while homogenization targets particle size reduction and consistent texture in food, pharmaceutical, and cosmetic industries.

Impact on Product Quality and Stability

Emulsification enhances product quality by creating stable mixtures of immiscible liquids, improving texture and shelf life through finely dispersed droplets that resist separation. Homogenization increases stability by evenly reducing particle size, producing uniform emulsions with consistent taste and appearance crucial for dairy and beverage industries. Both processes significantly influence product consistency, but emulsification primarily targets droplet dispersion, while homogenization emphasizes size reduction for enhanced stability and sensory attributes.

Advantages and Limitations of Each Process

Emulsification enhances the stability of mixtures by creating fine dispersions of immiscible liquids, offering advantages like improved texture and extended shelf life but may face limitations in droplet size uniformity and stability over time. Homogenization provides uniform particle size reduction, resulting in consistent texture and increased product stability, yet it requires high energy input and specialized equipment that may increase production costs. Your choice between emulsification and homogenization depends on the desired product characteristics and processing capabilities, balancing efficiency with cost and stability needs.

Choosing the Right Process: Factors to Consider

Choosing between emulsification and homogenization depends on factors such as droplet size control, product stability, and the nature of ingredients. Emulsification is preferred for creating stable mixtures of immiscible liquids, especially when oil and water phases must remain distinct yet blended. Homogenization is ideal for producing consistently fine particle sizes and uniform textures, commonly used in dairy processing and pharmaceuticals for enhanced product quality.

Emulsification vs Homogenization Infographic

libmatt.com

libmatt.com