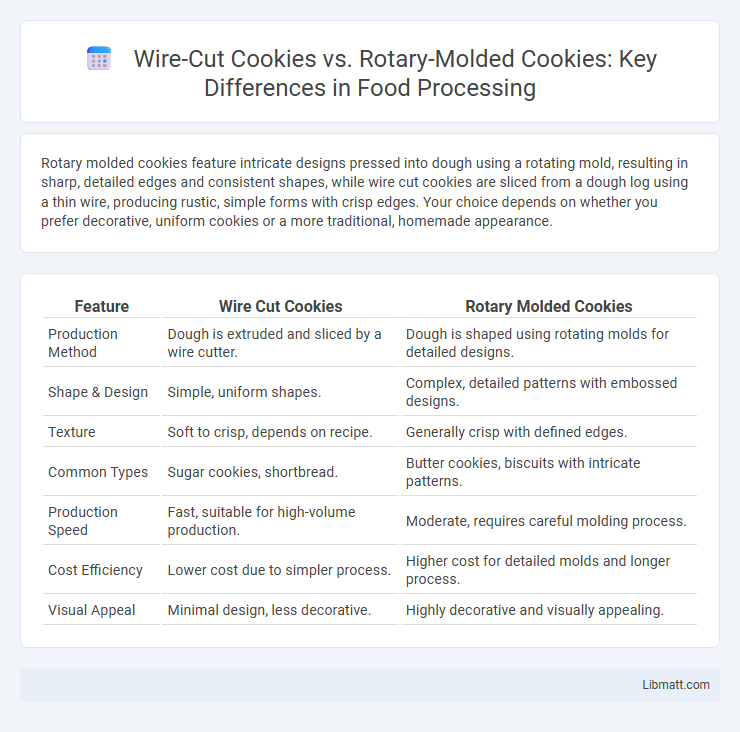

Rotary molded cookies feature intricate designs pressed into dough using a rotating mold, resulting in sharp, detailed edges and consistent shapes, while wire cut cookies are sliced from a dough log using a thin wire, producing rustic, simple forms with crisp edges. Your choice depends on whether you prefer decorative, uniform cookies or a more traditional, homemade appearance.

Table of Comparison

| Feature | Wire Cut Cookies | Rotary Molded Cookies |

|---|---|---|

| Production Method | Dough is extruded and sliced by a wire cutter. | Dough is shaped using rotating molds for detailed designs. |

| Shape & Design | Simple, uniform shapes. | Complex, detailed patterns with embossed designs. |

| Texture | Soft to crisp, depends on recipe. | Generally crisp with defined edges. |

| Common Types | Sugar cookies, shortbread. | Butter cookies, biscuits with intricate patterns. |

| Production Speed | Fast, suitable for high-volume production. | Moderate, requires careful molding process. |

| Cost Efficiency | Lower cost due to simpler process. | Higher cost for detailed molds and longer process. |

| Visual Appeal | Minimal design, less decorative. | Highly decorative and visually appealing. |

Introduction to Wire Cut and Rotary Molded Cookies

Wire cut cookies are made by extruding dough through a die and then slicing it with a wire to create uniform shapes, which results in a soft and chewy texture. Rotary molded cookies involve pressing dough into intricately designed molds that emboss patterns and produce a crisp, detailed finish. Your choice between these methods affects the cookie's texture, appearance, and overall eating experience.

Defining Wire Cut Cookies

Wire cut cookies are defined by their production method, where a dough log is sliced into individual cookies using a wire cutter, ensuring uniform thickness and shape. This technique is ideal for soft or chewy doughs, preventing deformation during shaping and preserving texture integrity. Unlike rotary molded cookies, wire cut variants typically have a simpler surface design due to the cutting process.

Understanding Rotary Molded Cookies

Rotary molded cookies are crafted by pressing dough into intricately designed molds that create detailed, sharp patterns on each cookie, preserving the dough's texture and shape during baking. Unlike wire cut cookies, which are sliced from a dough log and often have a rougher surface texture, rotary molded cookies showcase precise designs and uniform thickness, making them visually appealing and ideal for decorative purposes. Your choice between these types depends on the desired cookie appearance and texture, with rotary molded offering superior aesthetic detail and consistent form.

Differences in Dough Consistency

Wire cut cookies require a thicker, firmer dough to hold their shape during the cutting process, often resulting in a denser texture. Rotary molded cookies use a softer, more pliable dough that easily fills the mold, allowing for intricate patterns and a lighter, more delicate bite. Understanding these dough consistency differences helps you choose the right cookie style for your baking needs and desired texture.

Production Process Comparison

Wire cut cookies are produced by extruding dough through a die and slicing it with a heated wire, allowing for rapid shaping and consistent thickness, ideal for softer doughs. Rotary molded cookies use a patterned mold to press dough into intricate shapes, providing detailed designs and uniform texture, suited for firmer doughs. Your choice between these methods affects production speed, cookie texture, and the complexity of the final product's appearance.

Texture and Appearance Variations

Wire cut cookies feature a crumbly, tender texture with a rustic, uneven surface due to dough being sliced from a log, creating natural ridges and irregular shapes. Rotary molded cookies showcase a crisp, uniform texture and intricate, detailed patterns embossed by the mold, resulting in a polished, professional look. Your choice between these methods affects both the bite and visual appeal, with wire cut delivering a homemade feel and rotary molded providing consistent elegance.

Ingredient Suitability for Each Method

Wire cut cookies require dough with a higher fat content and lower moisture to maintain shape during slicing, favoring ingredients like butter, sugar, and flour in precise ratios for a firm yet pliable texture. Rotary molded cookies benefit from stiffer doughs rich in sugar and shortening, which hold intricate patterns and detailed shapes during molding and baking. Ingredient adjustments such as reduced leavening agents and controlled hydration are critical for rotary molding to prevent distortion and ensure consistent product quality.

Efficiency and Scale in Manufacturing

Wire cut cookies offer high efficiency in manufacturing due to their continuous dough extrusion process, allowing rapid production with minimal downtime. Rotary molded cookies excel in scale by producing intricate shapes and consistent thickness at high speeds, ideal for large-scale commercial operations. Both methods optimize throughput, but wire cutting suits simpler designs, while rotary molding supports complex, high-volume demands.

Common Uses and Popular Varieties

Wire cut cookies, commonly made from soft doughs like chocolate chip or oatmeal raisin, are popular for their classic, homemade texture and appearance, making them ideal for casual snacking or coffee breaks. Rotary molded cookies, produced using intricate molds, are often associated with European butter cookies and shortbread varieties, celebrated for their decorative shapes and crisp texture perfect for gifting and special occasions. You can choose wire cut cookies for everyday enjoyment or opt for rotary molded cookies when seeking a visually appealing treat.

Choosing the Right Cookie Formation Method

Choosing the right cookie formation method depends on your desired texture, shape precision, and production speed. Wire cut cookies offer a rustic appearance with variable thickness, ideal for chewy, drop-style cookies, while rotary molded cookies provide intricate designs and consistent shapes perfect for shortbread and butter cookies. Your choice will impact both the visual appeal and mouthfeel, ensuring your product meets customer expectations.

wire cut cookies vs rotary molded cookies Infographic

libmatt.com

libmatt.com