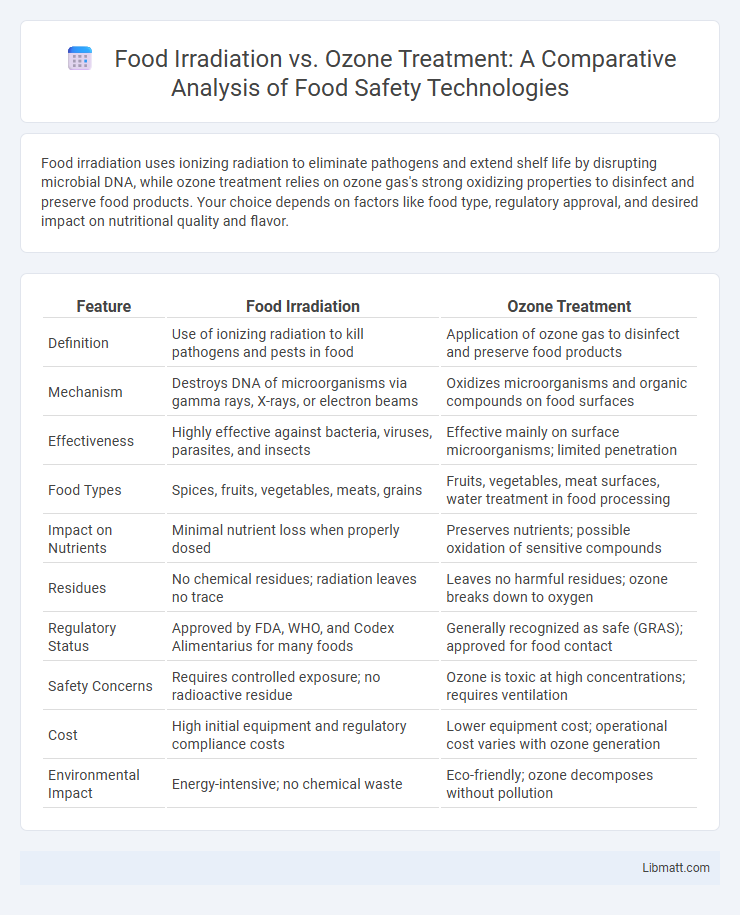

Food irradiation uses ionizing radiation to eliminate pathogens and extend shelf life by disrupting microbial DNA, while ozone treatment relies on ozone gas's strong oxidizing properties to disinfect and preserve food products. Your choice depends on factors like food type, regulatory approval, and desired impact on nutritional quality and flavor.

Table of Comparison

| Feature | Food Irradiation | Ozone Treatment |

|---|---|---|

| Definition | Use of ionizing radiation to kill pathogens and pests in food | Application of ozone gas to disinfect and preserve food products |

| Mechanism | Destroys DNA of microorganisms via gamma rays, X-rays, or electron beams | Oxidizes microorganisms and organic compounds on food surfaces |

| Effectiveness | Highly effective against bacteria, viruses, parasites, and insects | Effective mainly on surface microorganisms; limited penetration |

| Food Types | Spices, fruits, vegetables, meats, grains | Fruits, vegetables, meat surfaces, water treatment in food processing |

| Impact on Nutrients | Minimal nutrient loss when properly dosed | Preserves nutrients; possible oxidation of sensitive compounds |

| Residues | No chemical residues; radiation leaves no trace | Leaves no harmful residues; ozone breaks down to oxygen |

| Regulatory Status | Approved by FDA, WHO, and Codex Alimentarius for many foods | Generally recognized as safe (GRAS); approved for food contact |

| Safety Concerns | Requires controlled exposure; no radioactive residue | Ozone is toxic at high concentrations; requires ventilation |

| Cost | High initial equipment and regulatory compliance costs | Lower equipment cost; operational cost varies with ozone generation |

| Environmental Impact | Energy-intensive; no chemical waste | Eco-friendly; ozone decomposes without pollution |

Introduction to Food Irradiation and Ozone Treatment

Food irradiation uses ionizing radiation to eliminate pathogens and extend shelf life by disrupting microbial DNA, while ozone treatment employs ozone gas as a powerful oxidizing agent to disinfect and preserve food products. Both methods enhance food safety and reduce spoilage without compromising nutritional quality. Your choice between these technologies depends on factors like the type of food, regulatory acceptance, and desired treatment intensity.

How Food Irradiation Works

Food irradiation uses controlled doses of ionizing radiation, such as gamma rays, electron beams, or X-rays, to disrupt the DNA of bacteria, parasites, and insects, effectively reducing spoilage and pathogens. This process penetrates deep into food without significantly raising temperature, preserving texture and nutritional value while extending shelf life. Regulatory agencies like the FDA and WHO have approved irradiation as a safe method to enhance food safety and reduce foodborne illnesses.

Mechanism of Ozone Treatment in Food Processing

Ozone treatment in food processing utilizes ozone (O3) as a powerful oxidizing agent that disrupts microbial cell walls and inactivates enzymes responsible for spoilage. The strong oxidative properties of ozone lead to the breakdown of bacterial, viral, and fungal contaminants, enhancing food safety and extending shelf life. Unlike food irradiation, ozone leaves no chemical residues and decomposes rapidly back into oxygen, making it an environmentally friendly preservation method.

Comparative Effectiveness in Microbial Reduction

Food irradiation and ozone treatment both effectively reduce microbial contamination, but their mechanisms and efficacy levels differ. Food irradiation uses ionizing radiation to penetrate deep into food products, eliminating bacteria, viruses, and parasites with consistent microbial reduction rates often exceeding 99%. Ozone treatment, a potent oxidizing agent, is effective at surface-level decontamination and can reduce microbial loads significantly, though its penetration and uniformity in complex food matrices may be less consistent than irradiation.

Impact on Nutritional Quality

Food irradiation effectively reduces microbial load and extends shelf life while minimally affecting macronutrients like proteins, fats, and carbohydrates; however, some vitamins, particularly vitamin C and certain B vitamins, may degrade depending on the dose. Ozone treatment, used as a strong oxidizing agent, preserves most nutrients better than irradiation but can cause oxidation of sensitive compounds such as lipids and some vitamins. Comparative studies highlight ozone's advantage in maintaining antioxidant activity and phenolic content, making it preferable for nutrient retention in fresh produce.

Effects on Taste, Texture, and Appearance

Food irradiation can cause subtle changes in taste by inducing off-flavors due to lipid oxidation, while ozone treatment tends to preserve the original flavor profile more effectively. Texture alterations from irradiation may include softening or slight mushiness in fruits and vegetables, whereas ozone treatment generally maintains firmness and crispness. Appearance-wise, irradiation may cause minor discoloration or browning, but ozone treatment minimizes visual changes, keeping food fresh-looking and appealing.

Safety and Regulatory Aspects

Food irradiation and ozone treatment are both approved by international regulatory agencies such as the FDA and WHO, ensuring their safety when used within specified limits. Irradiation undergoes rigorous dose control to prevent nutrient loss and microbial resistance, while ozone treatment is valued for its rapid decomposition into non-toxic residues, minimizing chemical residues on food. Your choice between these methods should consider regulatory compliance, the type of food product, and consumer safety preferences.

Environmental Considerations

Food irradiation uses ionizing radiation to eliminate pathogens and extend shelf life, generating minimal chemical residues but raising concerns about energy consumption and radioactive source disposal. Ozone treatment, a natural oxidant, decomposes quickly without leaving harmful residues, promoting a more eco-friendly alternative with lower environmental impact. Both methods reduce the need for chemical preservatives, but ozone's rapid breakdown and lower energy requirements often result in a smaller ecological footprint compared to irradiation.

Cost and Scalability for Industry

Food irradiation generally involves higher initial capital investment due to specialized equipment like gamma irradiators or electron beam accelerators, but it offers consistent large-scale processing suitable for bulk products. Ozone treatment requires lower upfront costs with simpler equipment, making it more scalable for small to medium-sized operations, though maintaining effective ozone concentrations can raise operational expenses. Industry adoption depends on balancing fixed irradiation facility costs against ozone's flexible but sometimes less uniform scalability, influencing cost-efficiency across different production volumes.

Future Trends and Consumer Acceptance

Food irradiation and ozone treatment are emerging technologies with growing potential to enhance food safety and shelf life, driven by increasing demand for minimally processed, chemical-free preservation methods. Future trends indicate greater integration of these methods with smart packaging and blockchain for traceability, addressing consumer concerns about transparency and safety. Consumer acceptance is expected to improve as education on the benefits and regulatory approvals increase, highlighting reduced microbial risks without compromising nutritional quality.

food irradiation vs ozone treatment Infographic

libmatt.com

libmatt.com