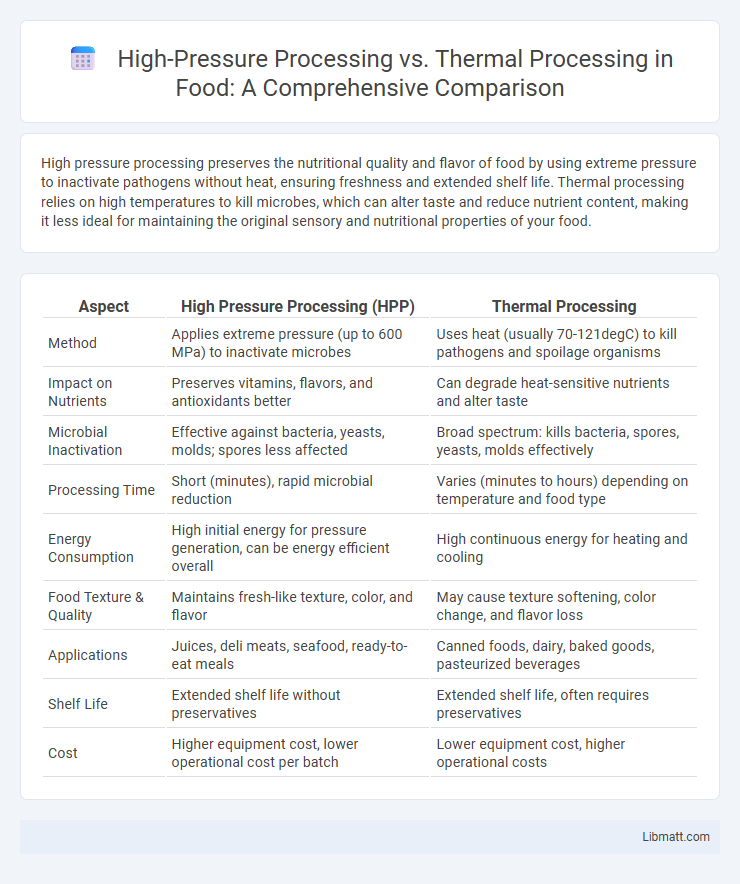

High pressure processing preserves the nutritional quality and flavor of food by using extreme pressure to inactivate pathogens without heat, ensuring freshness and extended shelf life. Thermal processing relies on high temperatures to kill microbes, which can alter taste and reduce nutrient content, making it less ideal for maintaining the original sensory and nutritional properties of your food.

Table of Comparison

| Aspect | High Pressure Processing (HPP) | Thermal Processing |

|---|---|---|

| Method | Applies extreme pressure (up to 600 MPa) to inactivate microbes | Uses heat (usually 70-121degC) to kill pathogens and spoilage organisms |

| Impact on Nutrients | Preserves vitamins, flavors, and antioxidants better | Can degrade heat-sensitive nutrients and alter taste |

| Microbial Inactivation | Effective against bacteria, yeasts, molds; spores less affected | Broad spectrum: kills bacteria, spores, yeasts, molds effectively |

| Processing Time | Short (minutes), rapid microbial reduction | Varies (minutes to hours) depending on temperature and food type |

| Energy Consumption | High initial energy for pressure generation, can be energy efficient overall | High continuous energy for heating and cooling |

| Food Texture & Quality | Maintains fresh-like texture, color, and flavor | May cause texture softening, color change, and flavor loss |

| Applications | Juices, deli meats, seafood, ready-to-eat meals | Canned foods, dairy, baked goods, pasteurized beverages |

| Shelf Life | Extended shelf life without preservatives | Extended shelf life, often requires preservatives |

| Cost | Higher equipment cost, lower operational cost per batch | Lower equipment cost, higher operational costs |

Introduction to Food Processing Methods

High Pressure Processing (HPP) and Thermal Processing are advanced food preservation techniques that enhance safety and shelf life by targeting microorganisms. HPP uses extremely high pressure, up to 600 MPa, to inactivate pathogens without significant heat, preserving flavor, nutrients, and texture. In contrast, Thermal Processing relies on heat treatments, such as pasteurization or sterilization, to destroy microbes but often impacts sensory and nutritional qualities more significantly.

Understanding High Pressure Processing (HPP)

High Pressure Processing (HPP) uses intense pressure, typically between 300 and 600 MPa, to inactivate pathogens and spoilage microorganisms in food, preserving freshness and nutritional quality without heat. This non-thermal method maintains the food's sensory attributes better than traditional thermal processing, which relies on high temperatures to kill microbes but can degrade taste, texture, and nutrients. HPP is particularly effective for juices, ready-to-eat meats, and seafood, extending shelf life while meeting food safety standards.

Overview of Thermal Processing Techniques

Thermal processing techniques, including pasteurization, sterilization, and blanching, use heat to inactivate microorganisms and enzymes in food products, ensuring safety and extended shelf life. These methods rely on temperature-time combinations calibrated to preserve nutritional quality while preventing spoilage and pathogens. Thermal processing remains widely adopted due to its simplicity and effectiveness but can sometimes degrade heat-sensitive nutrients and alter sensory properties.

Mechanisms: How HPP and Thermal Processing Work

High Pressure Processing (HPP) uses extremely high pressure, typically up to 600 MPa, to inactivate microorganisms and enzymes by disrupting their cellular functions without significantly raising the temperature, preserving the food's nutrients and sensory qualities. Thermal Processing relies on heat to denature proteins and enzymes, effectively killing pathogens through temperatures often exceeding 100degC, but this can lead to nutrient loss and altered taste or texture. Your choice between HPP and Thermal Processing depends on the desired balance between food safety, quality retention, and shelf life.

Impact on Food Safety and Shelf Life

High Pressure Processing (HPP) uses intense pressure to inactivate pathogens and spoilage microorganisms without the heat that can degrade nutrients, resulting in safer food with extended shelf life. Thermal Processing relies on high temperatures to kill harmful bacteria but may reduce sensory quality and nutrient content. Your choice between HPP and Thermal Processing influences both the safety and longevity of perishable foods, prioritizing either nutrient preservation or microbial inactivation.

Effects on Nutritional Value and Sensory Quality

High Pressure Processing (HPP) better preserves the nutritional value of foods by retaining vitamins and antioxidants that are often degraded during Thermal Processing due to high heat exposure. Your food's sensory quality, including texture, color, and flavor, is also maintained more effectively with HPP, resulting in fresher taste and appearance. Thermal Processing tends to cause nutrient loss and changes in sensory attributes such as softness and browning, impacting overall food quality.

Energy Consumption and Environmental Considerations

High Pressure Processing (HPP) consumes less energy compared to Thermal Processing due to its shorter processing times and lower temperature requirements, reducing overall carbon emissions. Thermal Processing relies heavily on continuous heating, leading to higher fuel usage and increased environmental impact through greenhouse gas emissions. Your choice of HPP can contribute to more sustainable food production by minimizing energy consumption and preserving product quality without extensive thermal input.

Cost-Effectiveness and Industrial Applications

High Pressure Processing (HPP) offers higher upfront equipment costs but reduces energy consumption and extends shelf life, making it cost-effective for premium products and small to medium-sized production runs. Thermal Processing, with lower initial investment and established scalability, remains economically viable for large-scale, high-volume food manufacturing despite higher ongoing energy expenses. Industrial applications favor HPP in fresh juices, ready-to-eat meals, and seafood for quality retention, while Thermal Processing dominates canned goods, dairy, and bulk commodities due to its proven efficacy and cost efficiency.

Consumer Perception and Market Trends

Consumer perception favors High Pressure Processing (HPP) due to its ability to preserve food freshness, nutrients, and natural flavors without additives, contrasting with Thermal Processing, which often results in nutrient loss and altered taste. Market trends indicate a growing demand for clean-label and minimally processed foods, driving HPP adoption in sectors like juices, deli meats, and dairy products. Your preference for healthier, fresher options aligns with this increasing shift toward non-thermal preservation methods in the food industry.

Future Prospects in Food Processing Technologies

High Pressure Processing (HPP) offers significant advantages over Thermal Processing by preserving nutrients, flavor, and texture while effectively inactivating pathogens, positioning it as a promising technology for future food safety and quality improvements. Innovations in scalable HPP equipment and integration with cold chain logistics enhance shelf life and reduce energy consumption, aligning with sustainable food processing goals. As consumer demand shifts towards minimally processed, clean-label products, the adoption of HPP is expected to expand rapidly, complementing or replacing traditional thermal methods in many applications.

High Pressure Processing vs Thermal Processing Infographic

libmatt.com

libmatt.com